Been a while since I had a c

Code: Select all

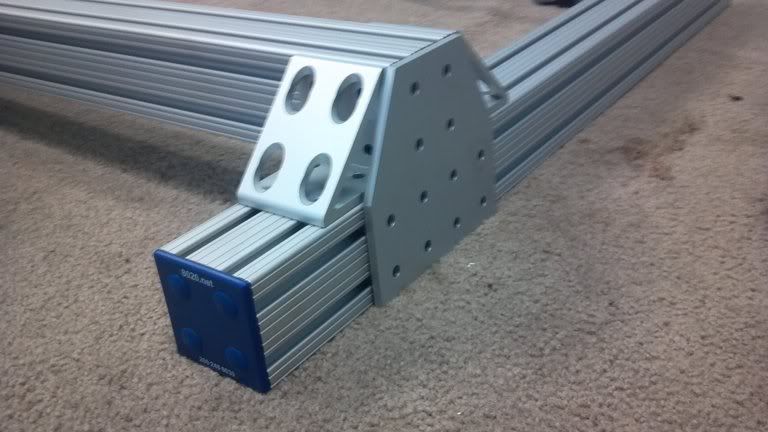

Are there any people out there who have constructed their own table using this system? It looks like a lot of the hardware has improved since I first look at this system, and I think I can put together a really nice 5 by 10 table with my budget which is about $4k. I already have a hypertherm 1250 G3 and most of the material to make my own gantry modeled after Prescision Plasmas gantry system.

Are you happy with the hardware and how hard it was to get a system up and running and what is the reliability factor once your table became operational? If you had to do it again would you go with c and c n c? Sorry 4 the bad grammar and spelling I'm on my cell phone at work