Hypertherm 45XP - Single side bevel

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Hypertherm 45XP - Single side bevel

Hello group, this is going to be long-winded so I apologize in advance.

I have been cutting on a Langmuir Crossfire Pro table (and non-Pro, both with THC) for about 2 years.

I have been running a PrimeWeld CUT60 for about 3 years, 2 of those years on CNC-duty for the above tables.

The last torch I used with my PrimeWeld CUT60 was my UPM-105 machine torch with PrimeWeld consumables. I only just sold this torch last week, but it was always running perfect and I've sold many parts cut on my table.

I switched to a Hypertherm 45XP that was purchased new, along with a genuine Hypertherm machine torch (Duramax consumable type), and genuine consumables. I also purchased a CPC kit as my machine didn't have it built in. This was approximately 2 months ago.

The issue - Switching over to the Hypertherm would give me beveling on an outside cut, X axis (top edge of a square). This bevel would range from 8-9 degrees and I went through an entire 2' x 4' of 3/16" mild steel trying to dial it in and fix the issue.

Mind you, the PrimeWeld CUT60 would cut a test piece, on the same piece of steel, which gave me as much as 1-2 degrees of bevel all around (as expected).

As of 2 days ago, I put my table back together, only to conduct a test cut piece and yet again, achieve about 9 degrees of bevel on the same exact top edge. To elaborate, I went through every possible scenario of troubleshooting to the point where I was still blaming something else and went as far as disassembling my table and reassembling it all over again. There are a few new bearings in the bearing blocks, a new torch mount, not to mention a completely new Z axis assembly.

I am looking for suggestions as to why this can happen.

If you have suggestions or advice, I am all ears. But I can preface by saying that I had completely exhausted my own knowledge and experience in troubleshooting everything for over a week, before contacting Langmuir and Hypertherm direct. My troubleshooting was so extensive even they couldn't figure it out.

Although the last person I spoke to yesterday was a different Hypertherm tech support and his words were - up to 8 degrees is within the range of tolerance that's acceptable. This isn't waterjet or laser. And why it only appears on one side is unheard of to me but what you are getting is what we would see in our own test samples. There is no secret sauce that'll make our plasma cutter cut better. It's the reliability, and the extended life of our consumables that would make it better than a non-Hypertherm.

To which my response is basically the same it has been to others - I know this isn't waterjet, I know this isn't laser. But I just find myself regretting buying an expensive plasma cutter, with expensive machine torch, only for them to perform worse than a cheaper, Chinese plasma cutter.

A part of me is willing to accept this one sided bevel, but another part of me is saying I must be overlooking something.

I have been cutting on a Langmuir Crossfire Pro table (and non-Pro, both with THC) for about 2 years.

I have been running a PrimeWeld CUT60 for about 3 years, 2 of those years on CNC-duty for the above tables.

The last torch I used with my PrimeWeld CUT60 was my UPM-105 machine torch with PrimeWeld consumables. I only just sold this torch last week, but it was always running perfect and I've sold many parts cut on my table.

I switched to a Hypertherm 45XP that was purchased new, along with a genuine Hypertherm machine torch (Duramax consumable type), and genuine consumables. I also purchased a CPC kit as my machine didn't have it built in. This was approximately 2 months ago.

The issue - Switching over to the Hypertherm would give me beveling on an outside cut, X axis (top edge of a square). This bevel would range from 8-9 degrees and I went through an entire 2' x 4' of 3/16" mild steel trying to dial it in and fix the issue.

Mind you, the PrimeWeld CUT60 would cut a test piece, on the same piece of steel, which gave me as much as 1-2 degrees of bevel all around (as expected).

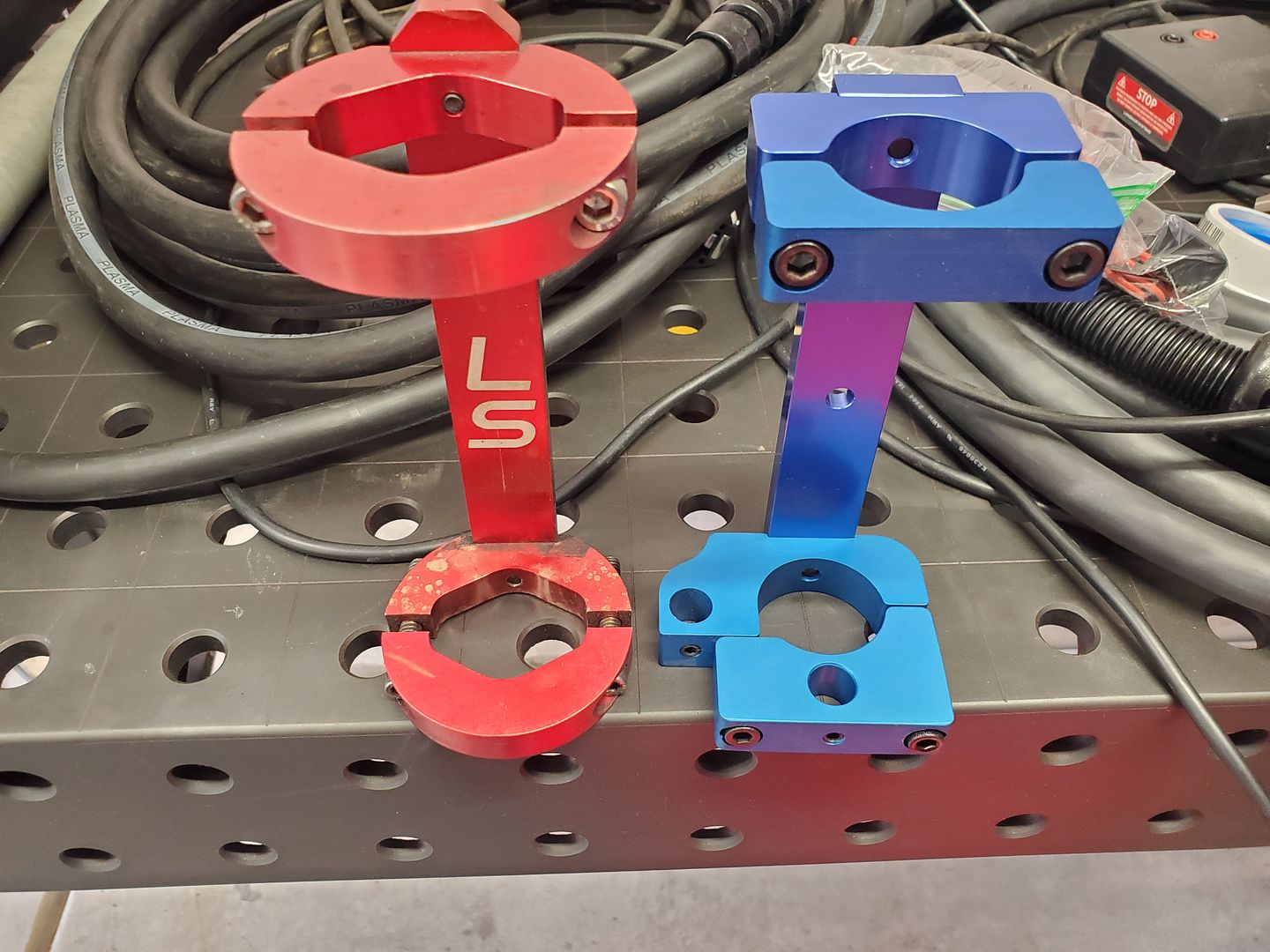

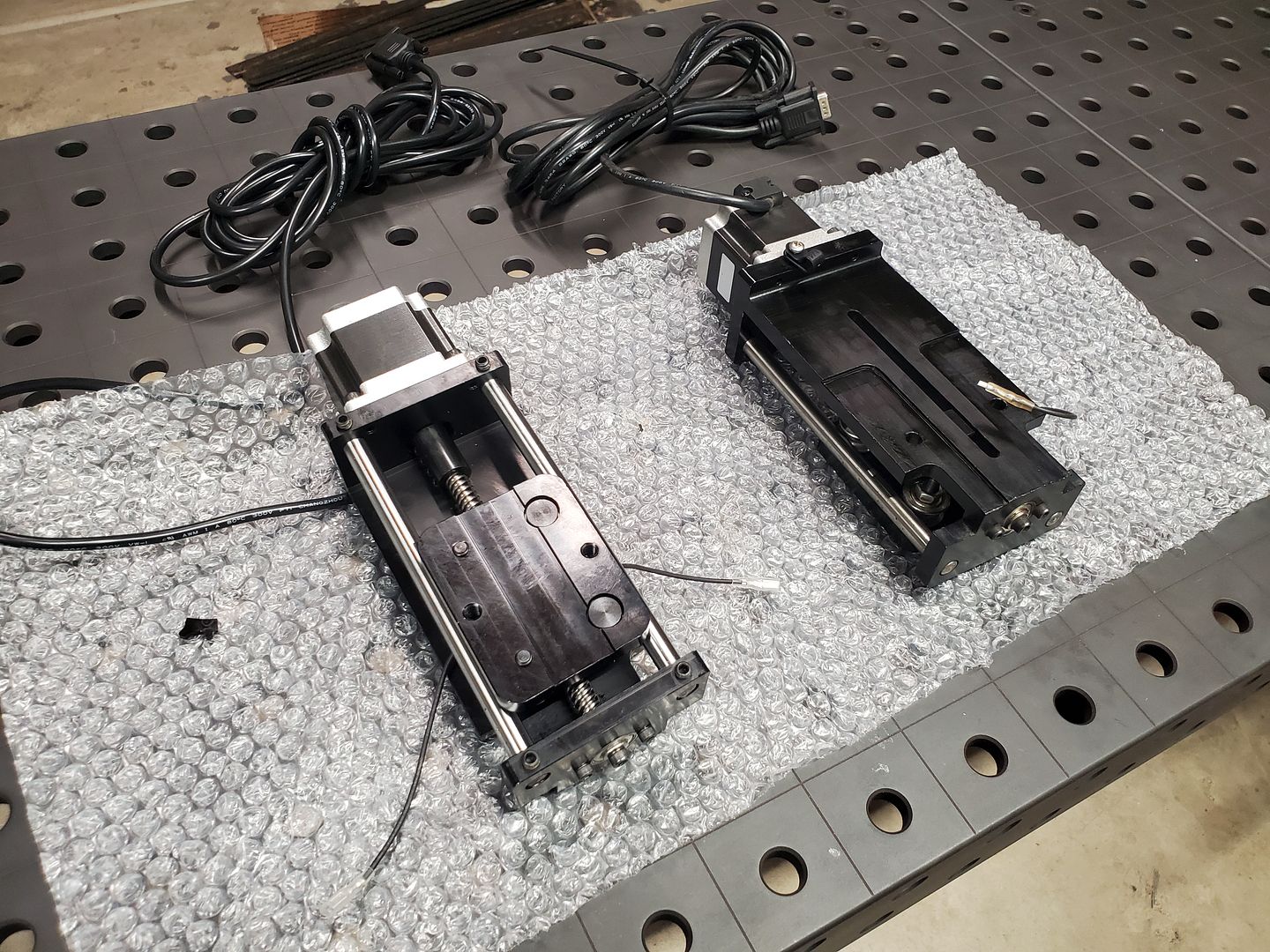

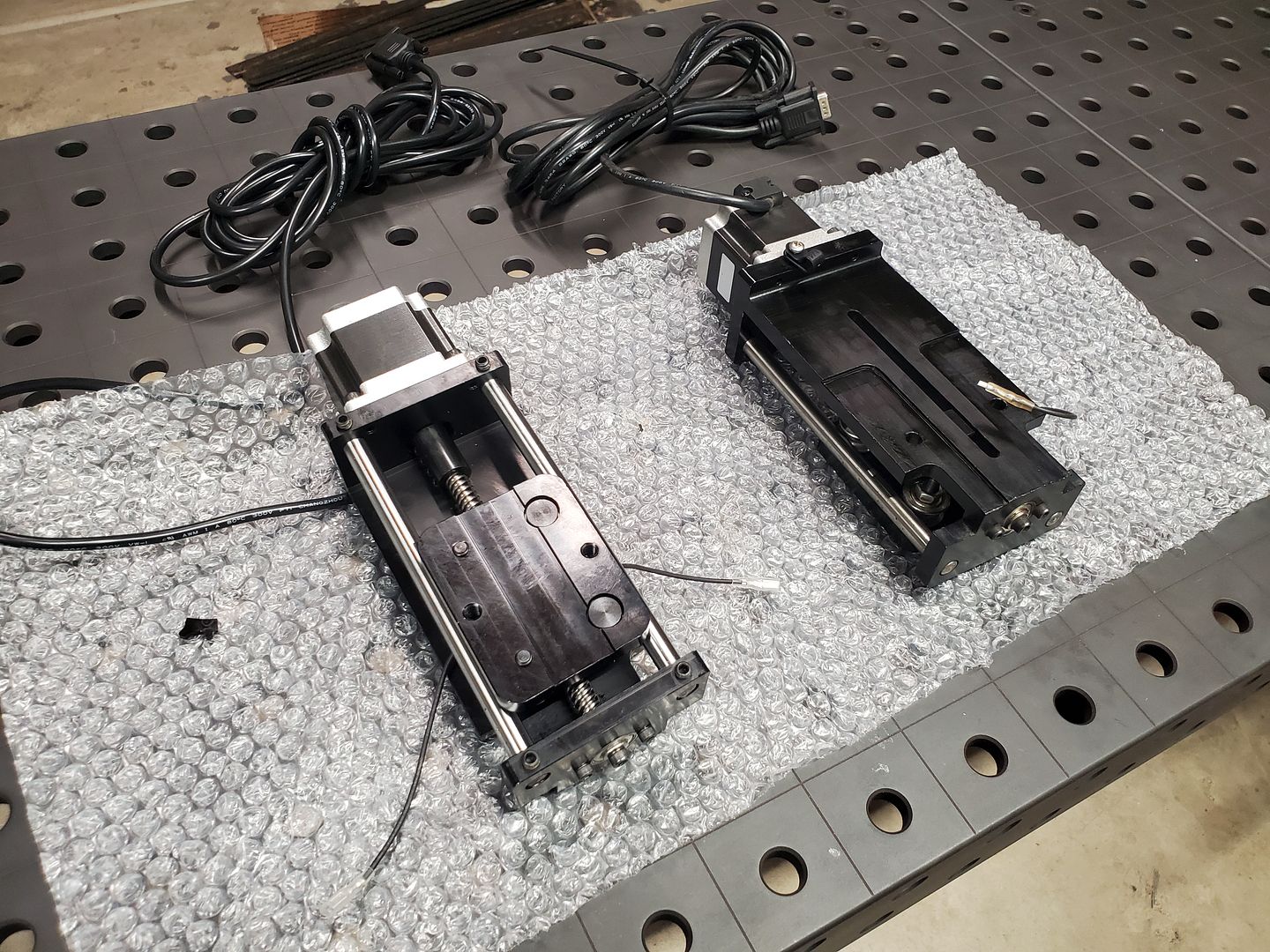

As of 2 days ago, I put my table back together, only to conduct a test cut piece and yet again, achieve about 9 degrees of bevel on the same exact top edge. To elaborate, I went through every possible scenario of troubleshooting to the point where I was still blaming something else and went as far as disassembling my table and reassembling it all over again. There are a few new bearings in the bearing blocks, a new torch mount, not to mention a completely new Z axis assembly.

I am looking for suggestions as to why this can happen.

If you have suggestions or advice, I am all ears. But I can preface by saying that I had completely exhausted my own knowledge and experience in troubleshooting everything for over a week, before contacting Langmuir and Hypertherm direct. My troubleshooting was so extensive even they couldn't figure it out.

Although the last person I spoke to yesterday was a different Hypertherm tech support and his words were - up to 8 degrees is within the range of tolerance that's acceptable. This isn't waterjet or laser. And why it only appears on one side is unheard of to me but what you are getting is what we would see in our own test samples. There is no secret sauce that'll make our plasma cutter cut better. It's the reliability, and the extended life of our consumables that would make it better than a non-Hypertherm.

To which my response is basically the same it has been to others - I know this isn't waterjet, I know this isn't laser. But I just find myself regretting buying an expensive plasma cutter, with expensive machine torch, only for them to perform worse than a cheaper, Chinese plasma cutter.

A part of me is willing to accept this one sided bevel, but another part of me is saying I must be overlooking something.

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

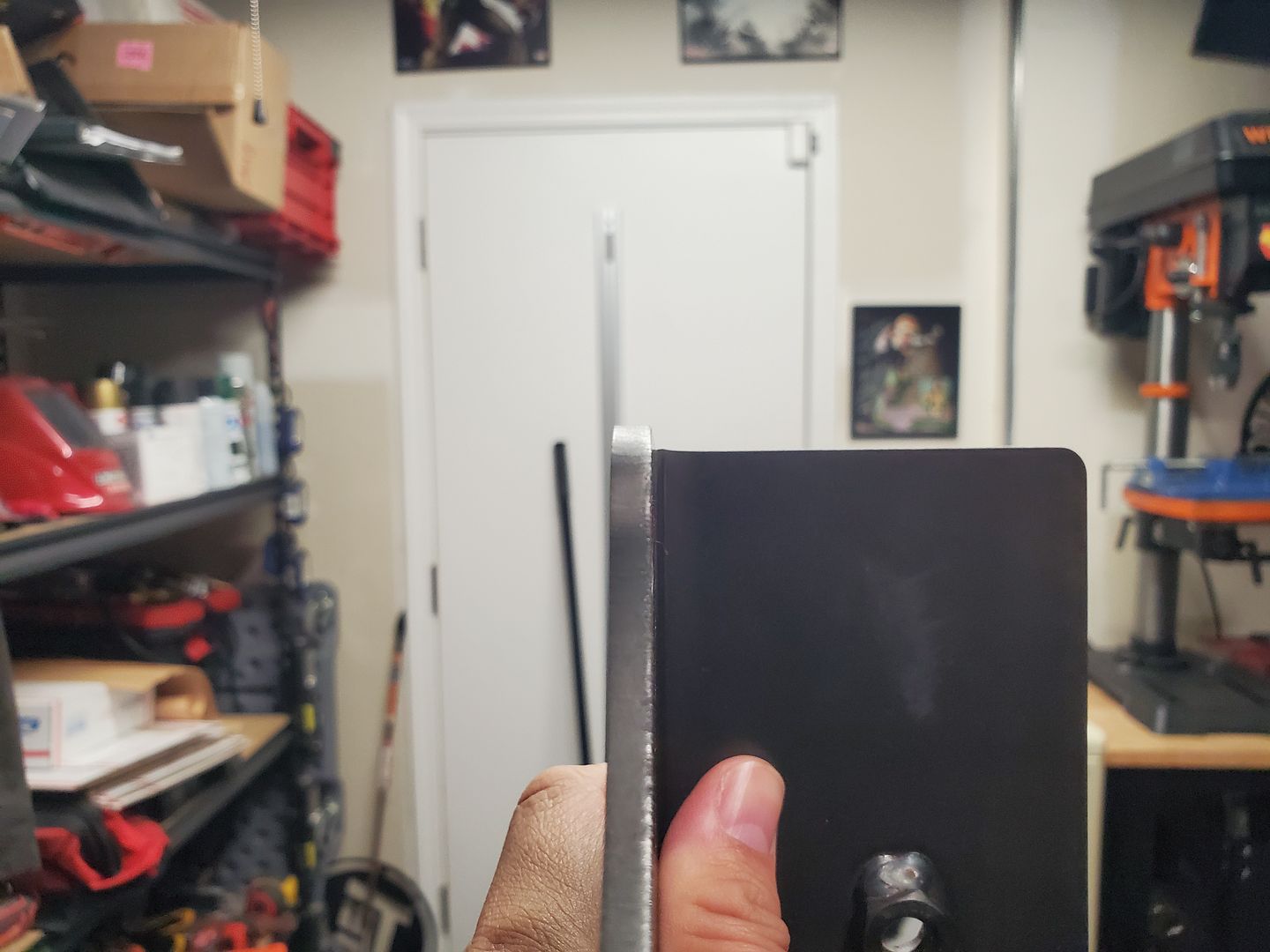

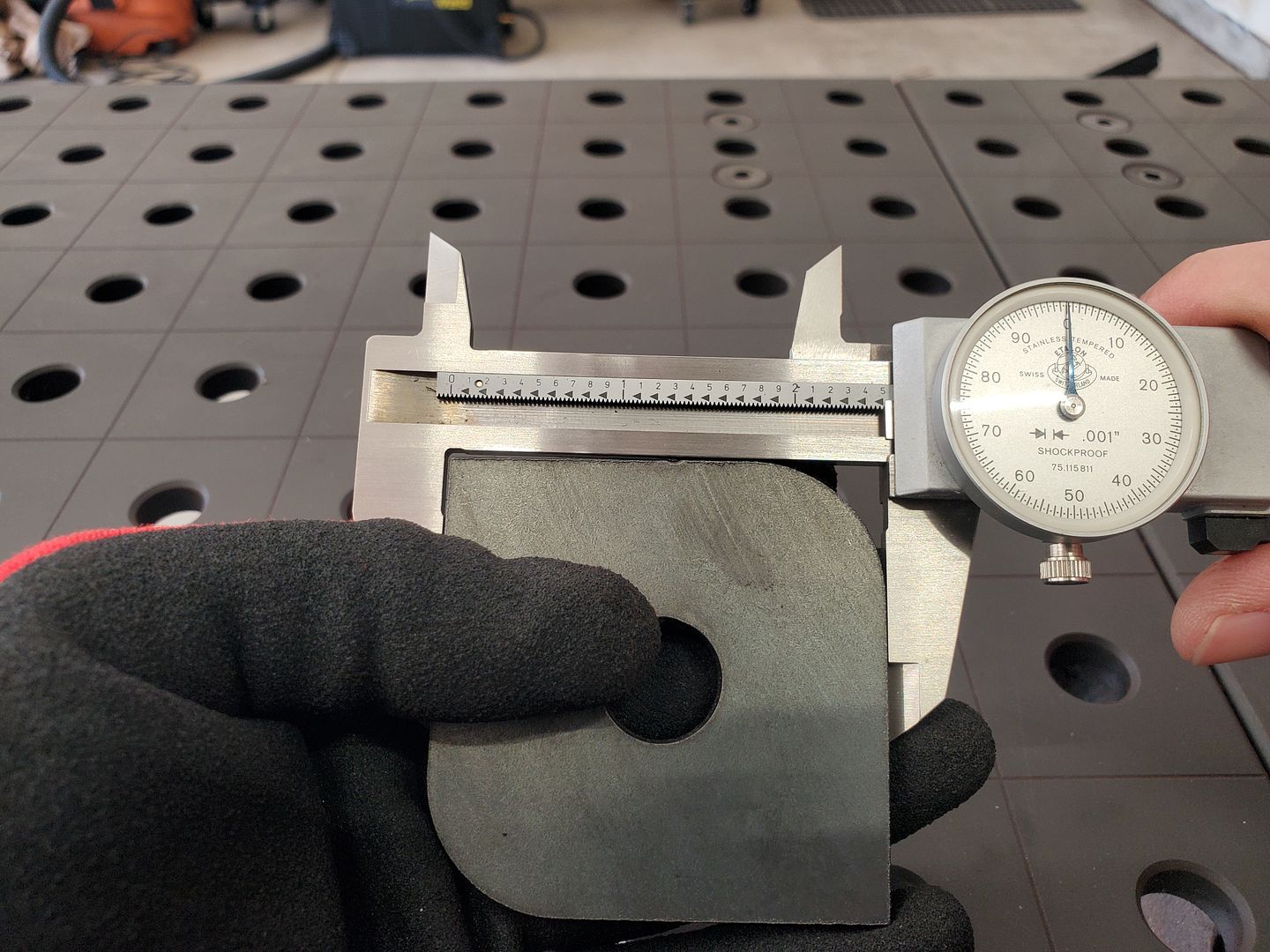

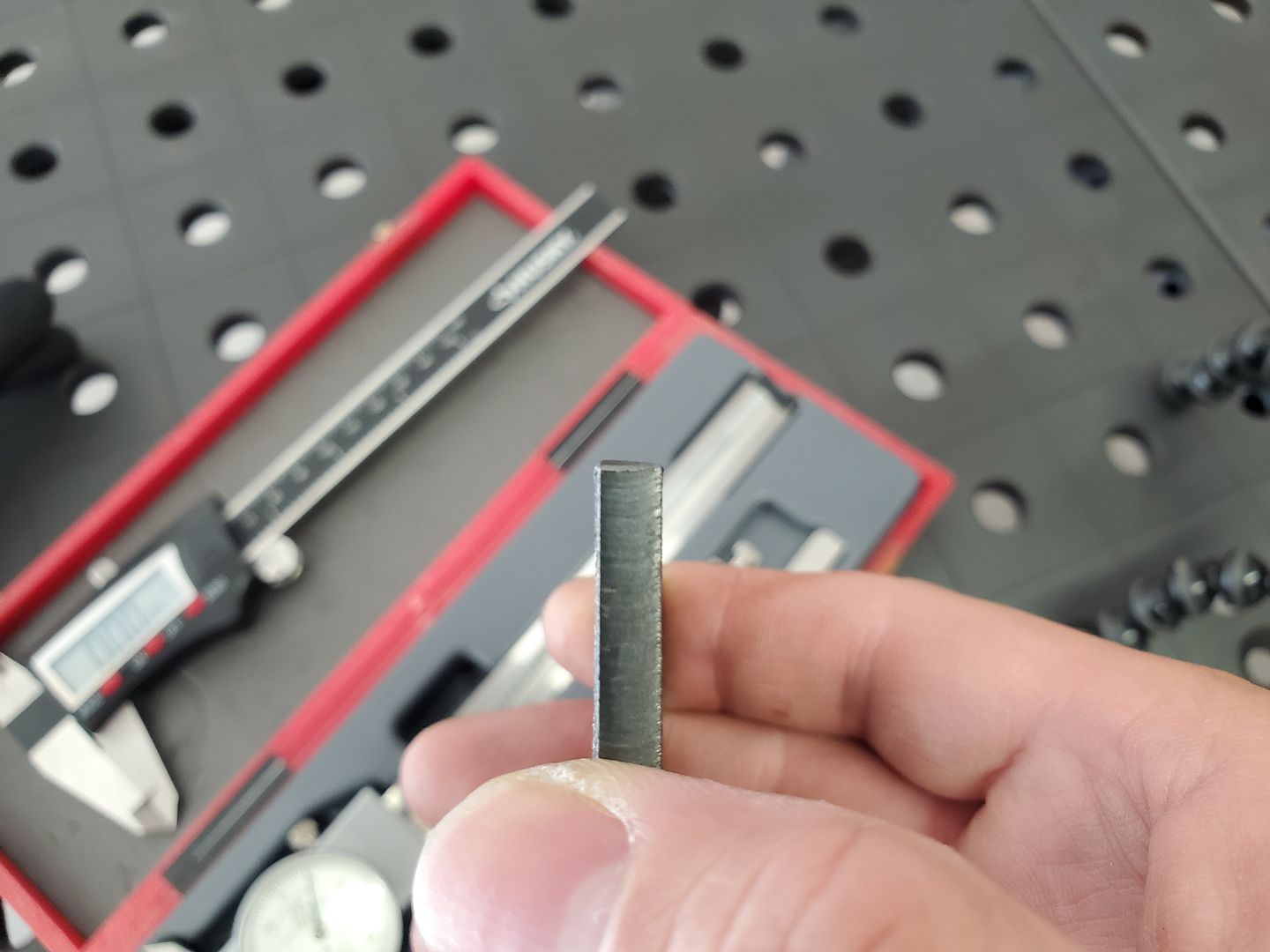

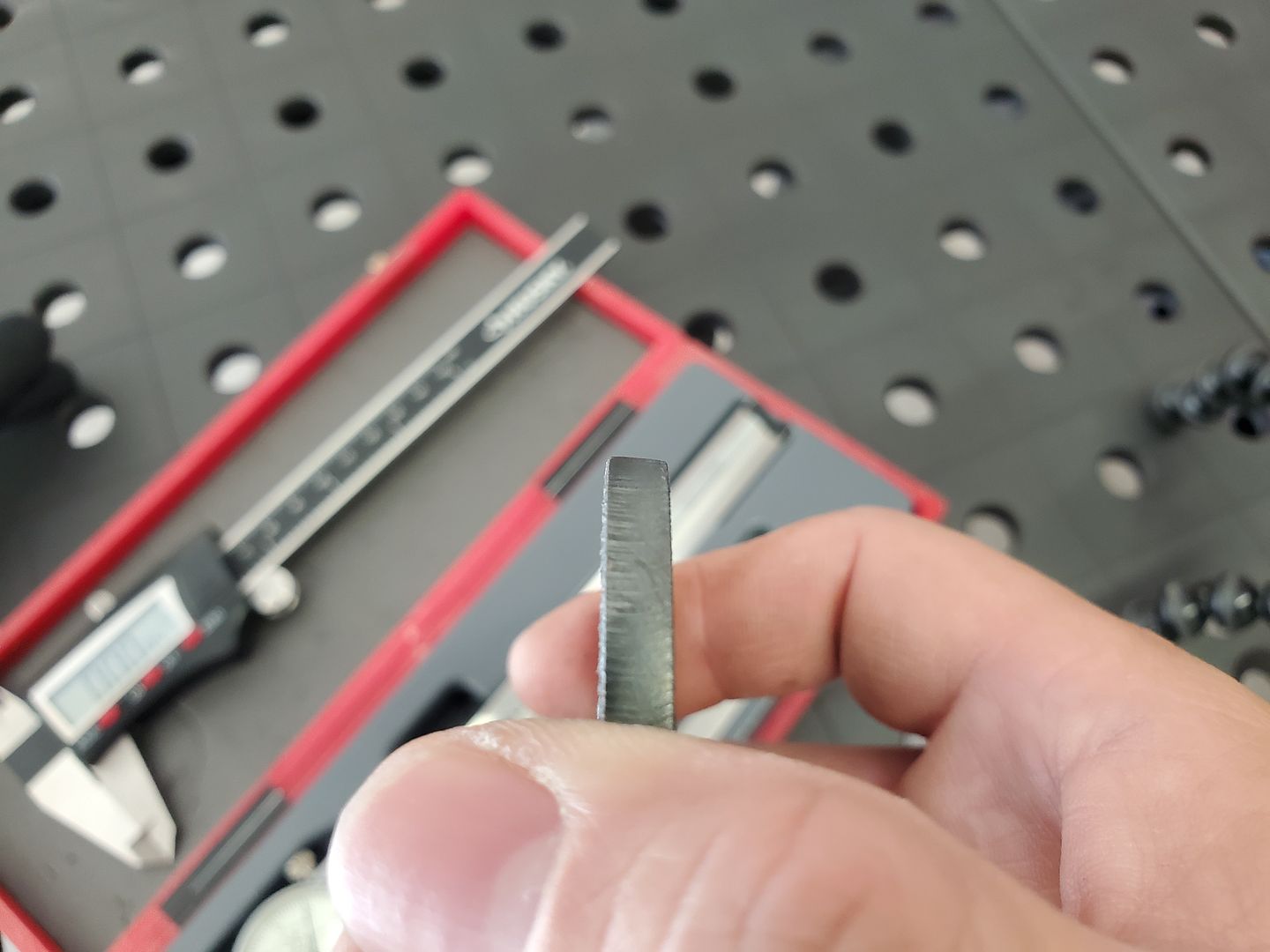

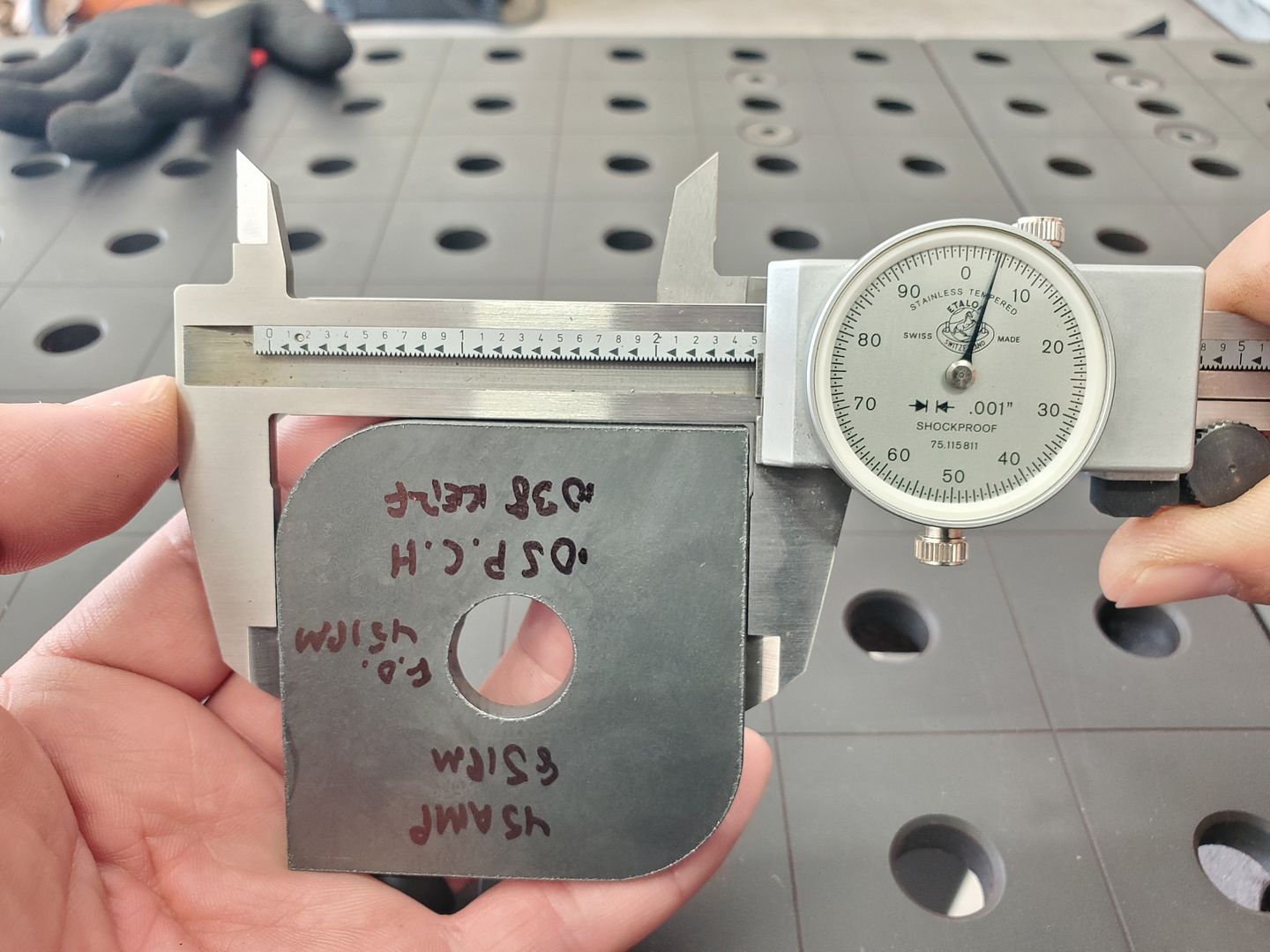

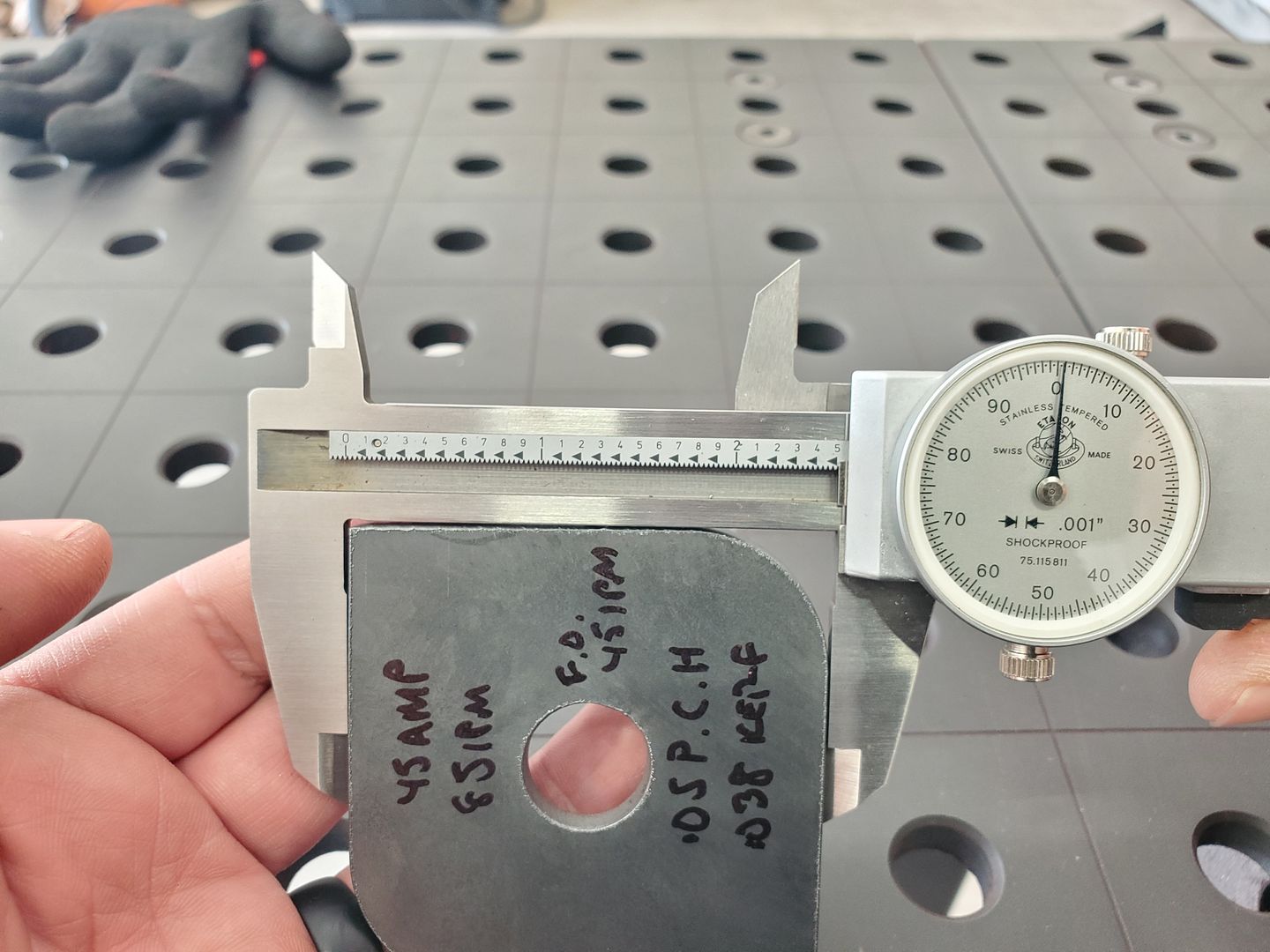

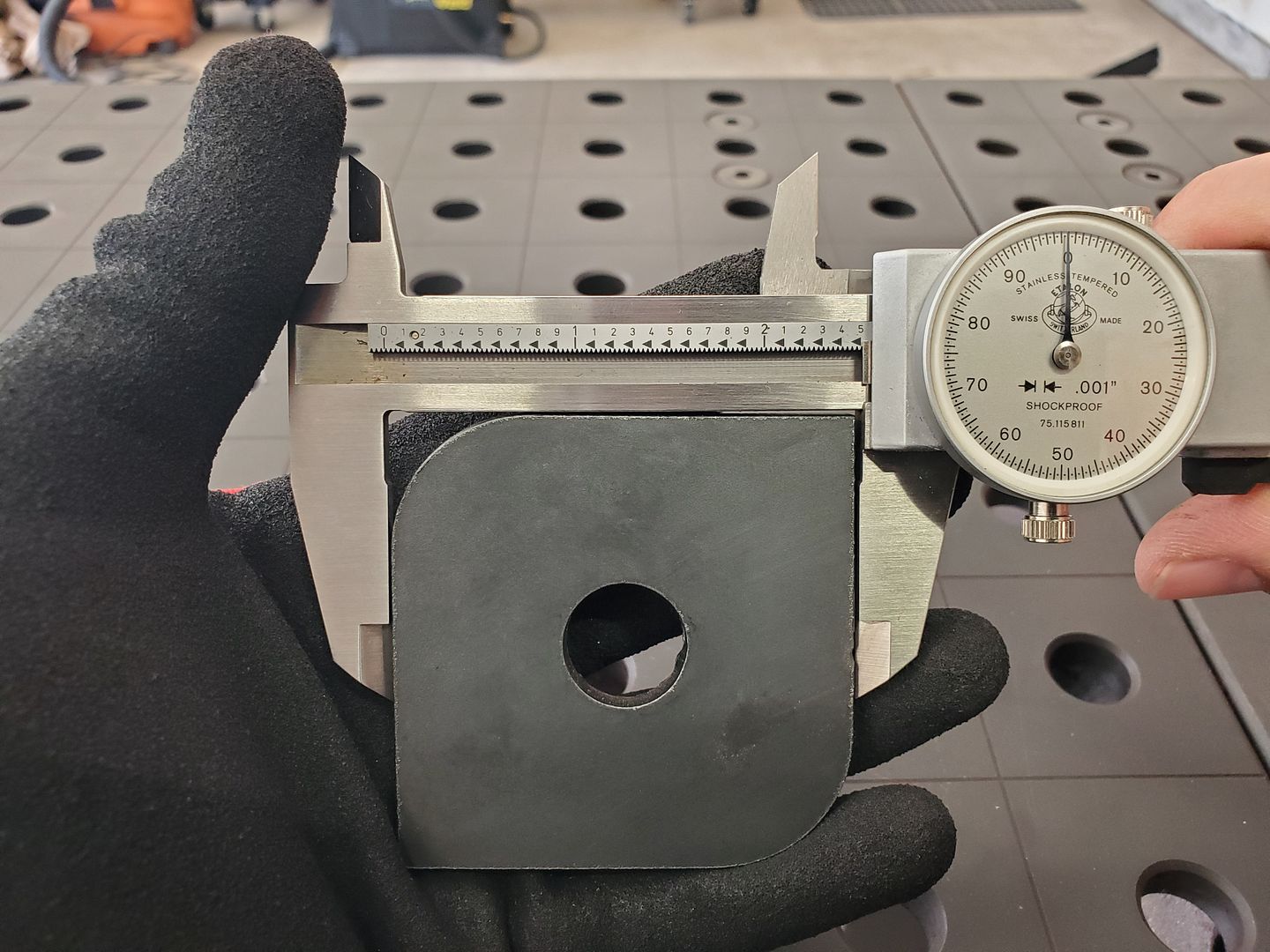

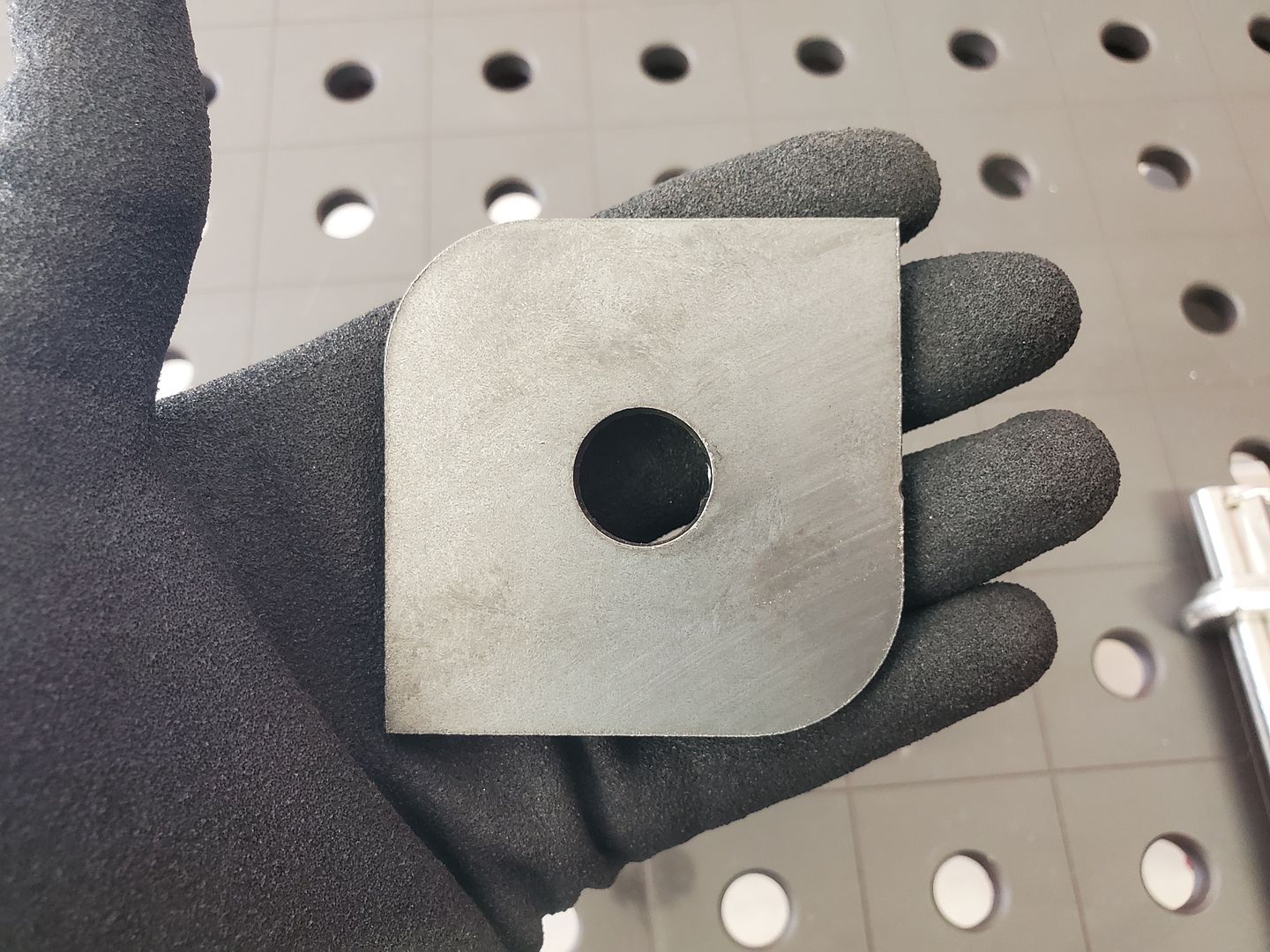

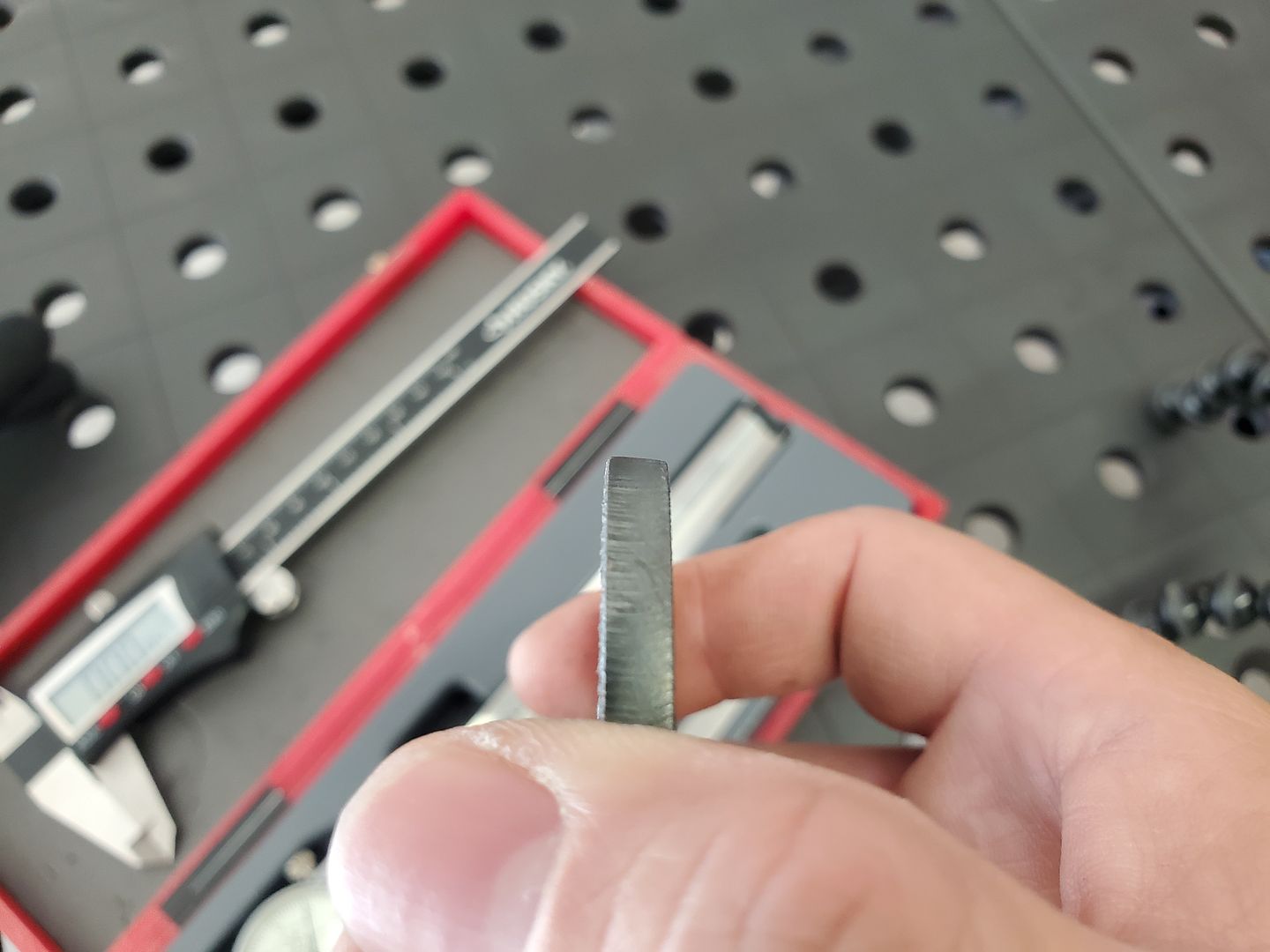

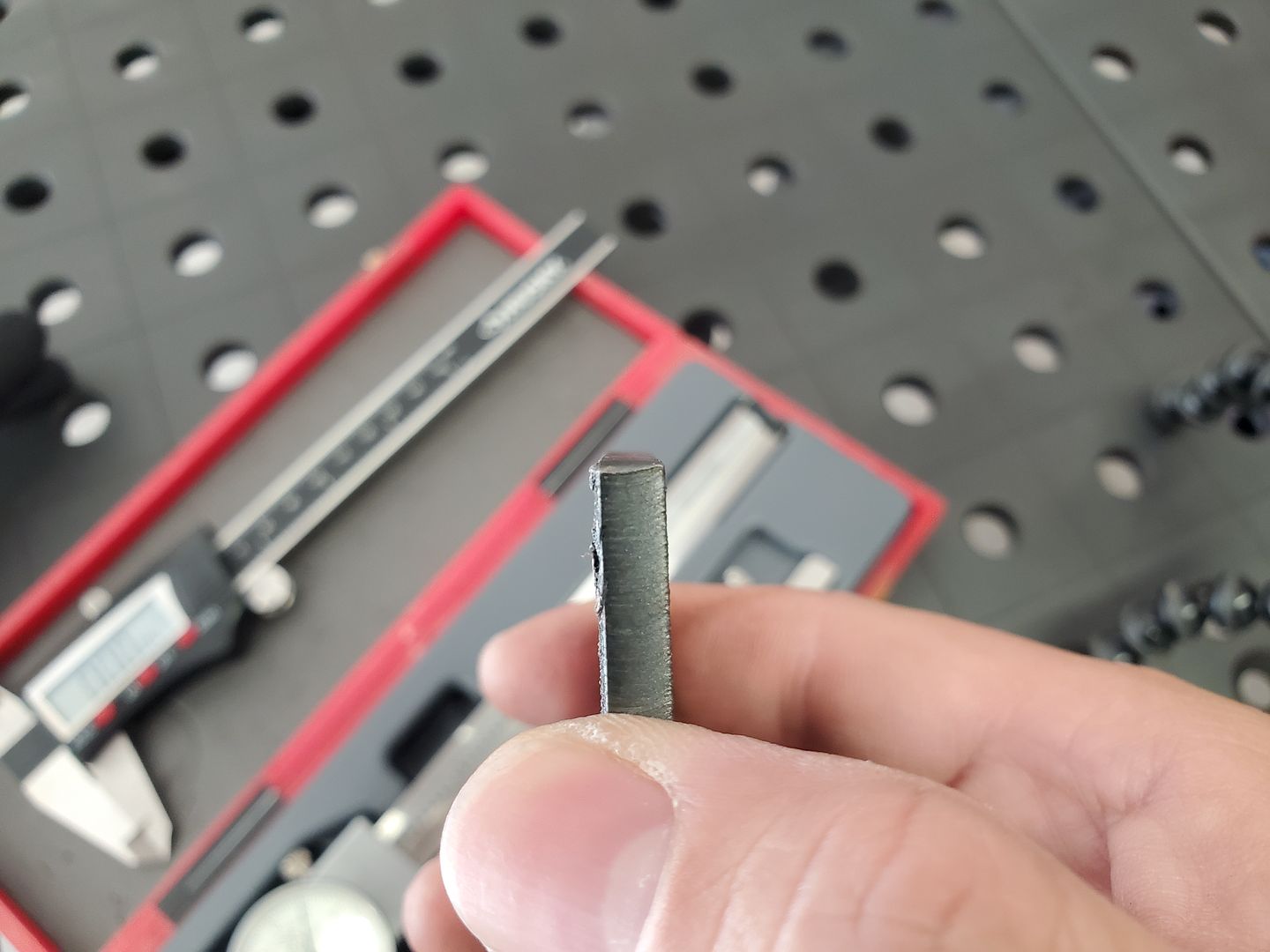

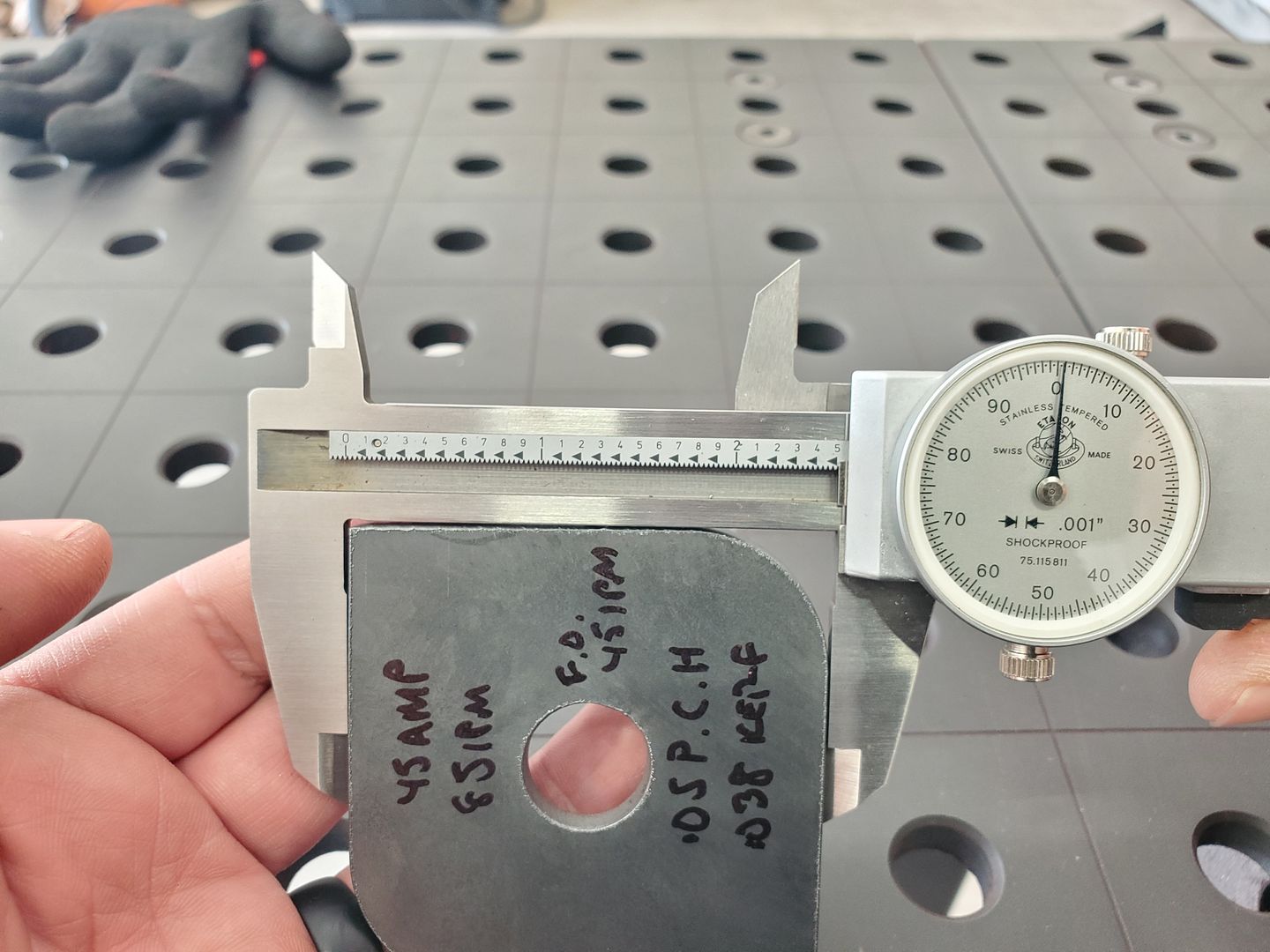

This is an example of the PrimeWeld CUT60's cuts, both a part I make often cut a day or two prior to running the Hypertherm, as well as one while troubleshooting between both machines.

3/16" mild steel, 65ipm, 38amps, 45 amp nozzle, 70psi

3/16" mild steel, 65ipm, 38amps, 45 amp nozzle, 70psi

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

And I won't overwhelm anyone here with tons of pictures but, the parts are basically the same from one to another with an 8-9 degree bevel on top only, on the same exact sheet of 3/16" mild steel as above.

As far as settings, everything from smartvoltage (THC using programmed torch height), to nominal voltage using book value and doing test cuts from as low as 123 volts to as high as 131 volts, as well as using book value for speed and adjusting as low as 60ipm to as high as 95ipm. The tests were also run with THC off not to mention Langmuir and 2 friends providing me their own TAP and NC files to eliminate the possibility of a CAM issue on my end.

Any and all settings changed provide the same results with significantly more bevel on top, and very good quality on the remaining 3 edges.

I have an entire small box of test cuts all with beveling that occurs on the top edge. Regardless of where my start point is on the piece, regardless of where on the table it is cut from.

I am just not completely convinced that my Hypertherm should cut worse than my PrimeWeld.

As far as settings, everything from smartvoltage (THC using programmed torch height), to nominal voltage using book value and doing test cuts from as low as 123 volts to as high as 131 volts, as well as using book value for speed and adjusting as low as 60ipm to as high as 95ipm. The tests were also run with THC off not to mention Langmuir and 2 friends providing me their own TAP and NC files to eliminate the possibility of a CAM issue on my end.

Any and all settings changed provide the same results with significantly more bevel on top, and very good quality on the remaining 3 edges.

I have an entire small box of test cuts all with beveling that occurs on the top edge. Regardless of where my start point is on the piece, regardless of where on the table it is cut from.

I am just not completely convinced that my Hypertherm should cut worse than my PrimeWeld.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

Question you say the bevel is on one side only, your X direction. If cutting a square it is on the 2 sides in the X direction. If the torch is not perpendicular the bevel should be opposite to each side. There can be a out of round with the nozzle opening, this would cause the plasma stream to be off. Have you rotated the torch in its mount to see if the bevel changes?? Torch height can cause a bevel but that should be on all sides.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

"Top side" based on your picture.acourtjester wrote: Fri Oct 11, 2024 6:20 pm Question you say the bevel is on one side only, your X direction. If cutting a square it is on the 2 sides in the X direction. If the torch is not perpendicular the bevel should be opposite to each side. There can be a out of round with the nozzle opening, this would cause the plasma stream to be off. Have you rotated the torch in its mount to see if the bevel changes?? Torch height can cause a bevel but that should be on all sides.

bevel cut.JPG

Opposing side, no effects.

Those suggestions were basically on day 1 of troubleshooting. I don't want to come off as abrasive, but I'm looking for out of the box suggestions as I believe I've done 95% of all troubleshooting anyone can think of. But I want to try something new that someone else may be able to suggest.

But to answer your question, yes of course. Torch has been rotated 45, 90, and 180, using the "enable/disable" switch as my indicator for knowing how much I rotated my torch within the mount. This resulted in the top side getting bevel still.

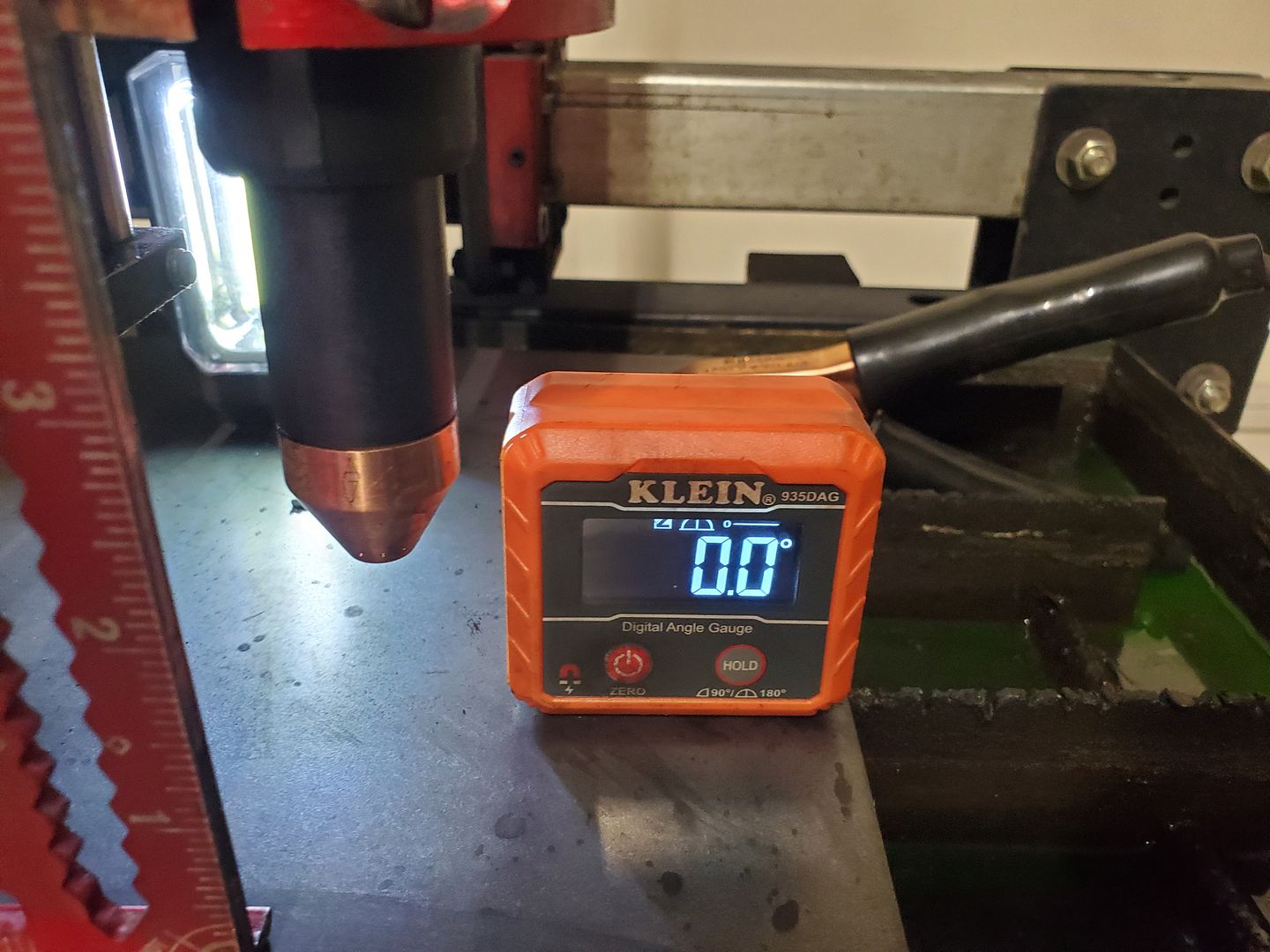

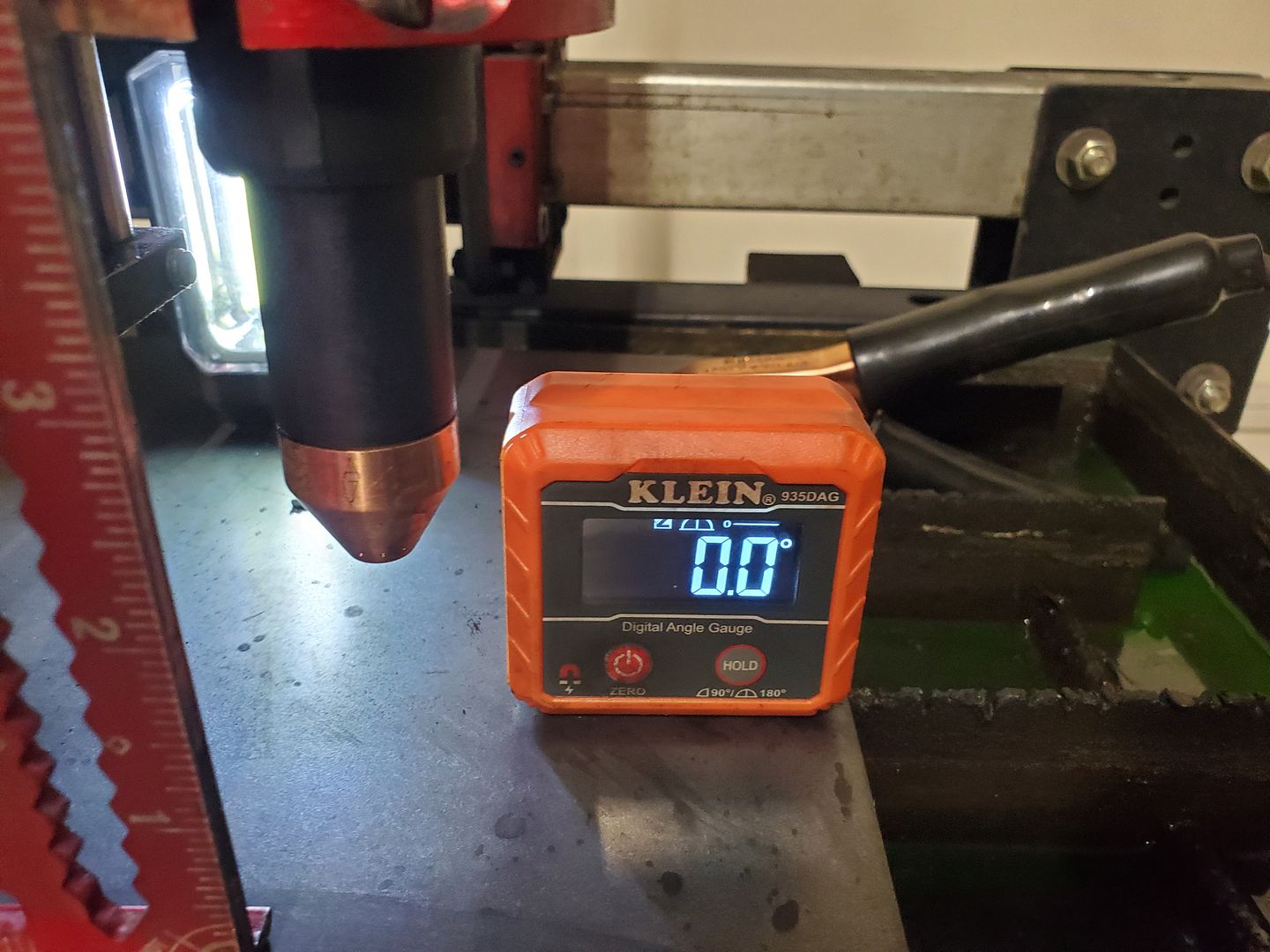

Z axis was fully trammed to ensure square against the work piece, about 12-13 times. Table is/was completely level and placing a level on any gantry tube, torch mount, work piece, anywhere would exhibit this.

Then I completely un-assembled the table and reassembled everything again, including undoing all the bearing blocks and more, only to achieve the same result. Mind you, the reassembly is utilizing a completely different Z axis assembly and again trammed to ensure squareness.

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

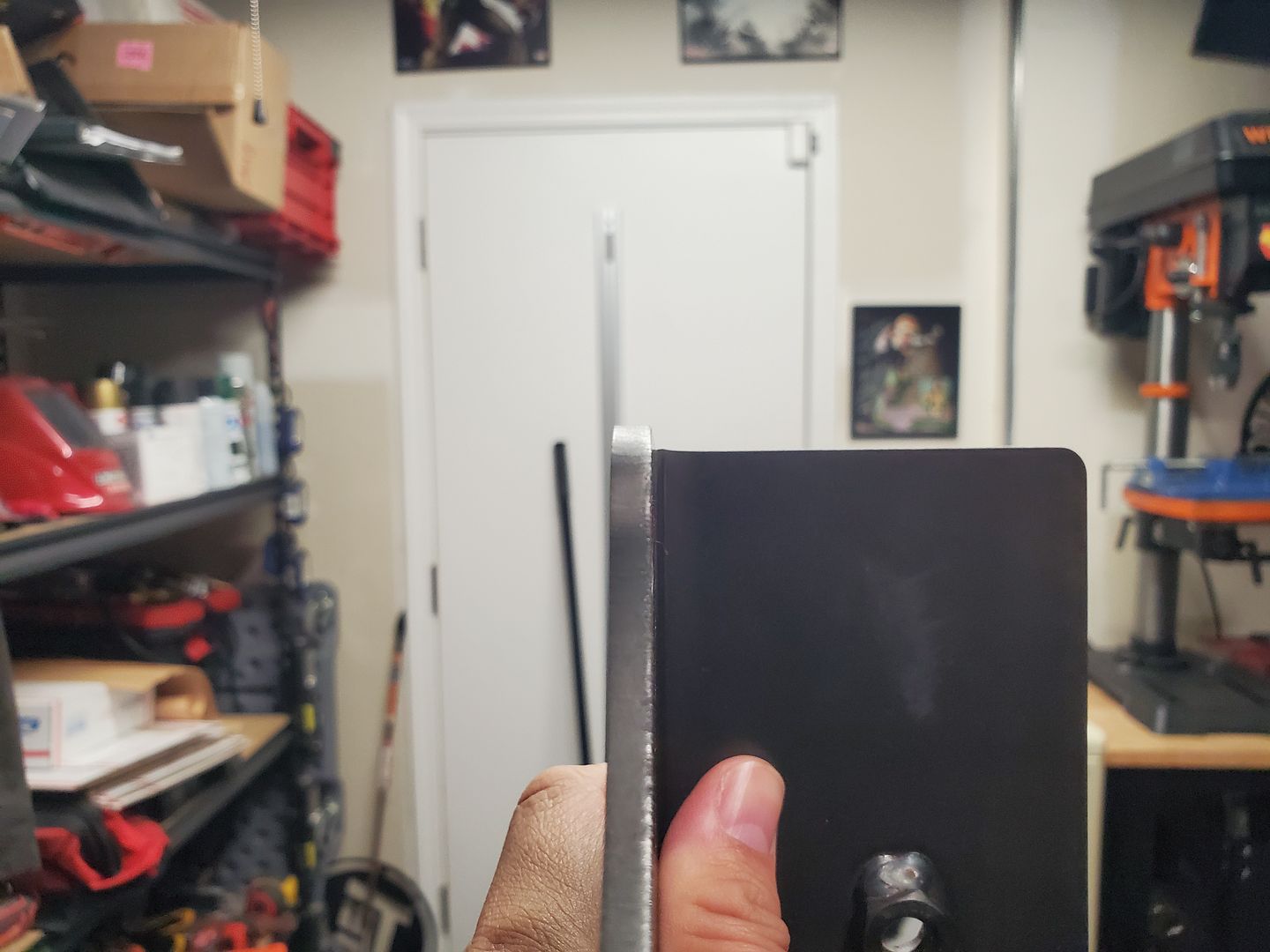

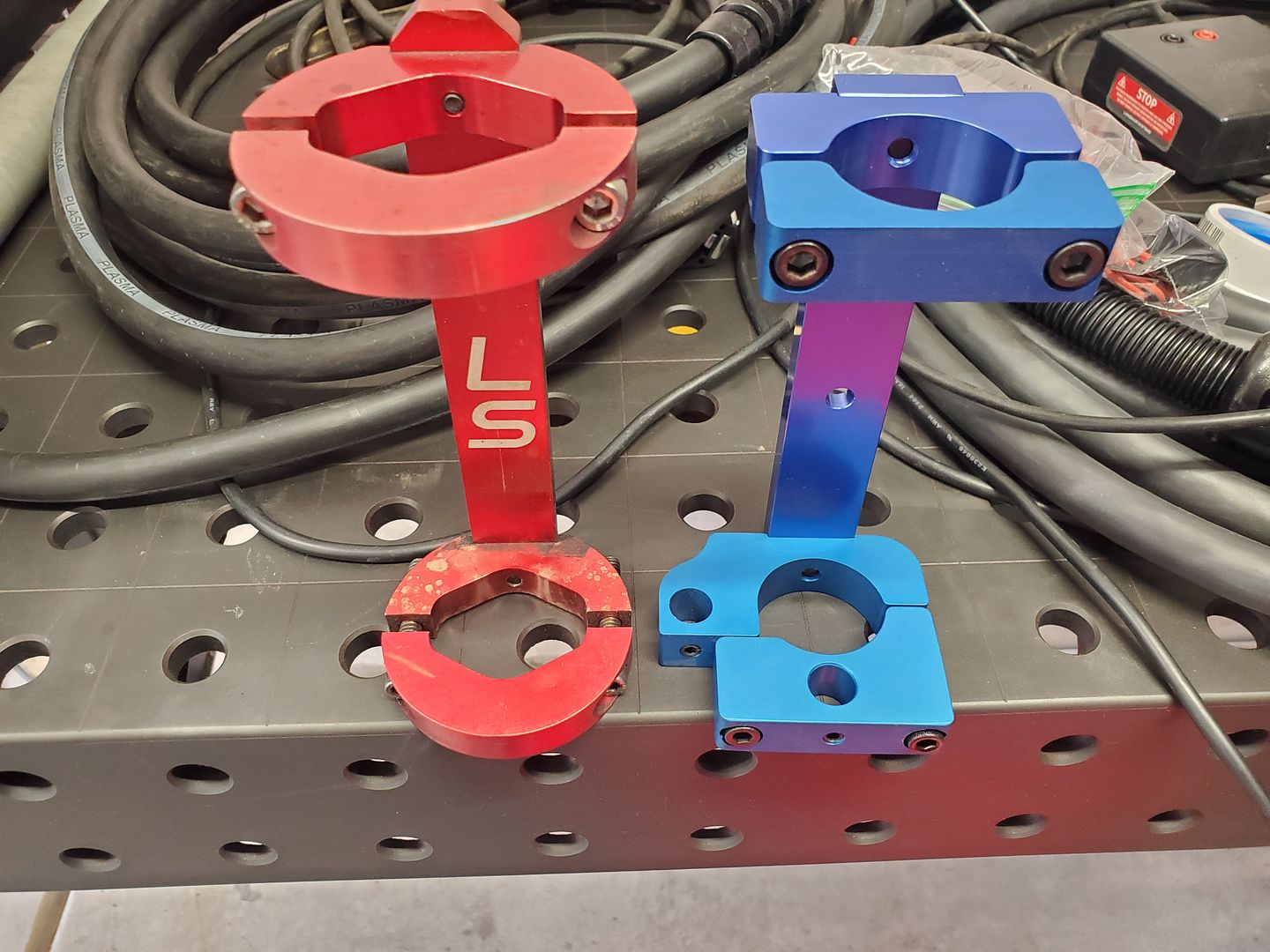

The old torch mount was replaced, new or old same effect -

Z axis mount replaced, new or old same effect -

Complete Z axis assembly replaced, new or old same effect -

If the torch was not perpendicular to the work piece, I cannot imagine that fully disassembling the entire frame and completely reassembling it would result in the same amount of "out of squareness" to achieve identical cut results.

I won't overwhelm with pictures of a level on every part of the table but even my angle finder was showing 0 to 90 from torch to work piece.

But also a reminder, a day or two before incorporating the Hypertherm, my PrimeWeld was cutting square on the same table, on the same material.

Z axis mount replaced, new or old same effect -

Complete Z axis assembly replaced, new or old same effect -

If the torch was not perpendicular to the work piece, I cannot imagine that fully disassembling the entire frame and completely reassembling it would result in the same amount of "out of squareness" to achieve identical cut results.

I won't overwhelm with pictures of a level on every part of the table but even my angle finder was showing 0 to 90 from torch to work piece.

But also a reminder, a day or two before incorporating the Hypertherm, my PrimeWeld was cutting square on the same table, on the same material.

-

weldguy

- 4.5 Star Elite Contributing Member

- Posts: 2377

- Joined: Fri Apr 17, 2009 11:48 am

Re: Hypertherm 45XP - Single side bevel

If your cutting a square and bevel is the same on all 4

sides for example tapered outwards from top to bottom or inwards from top to bottom it is likely a cut height issue. If the bevel is only on 2 side and in the same direction it is likely a bad nozzle with an orifice that is no longer round.

sides for example tapered outwards from top to bottom or inwards from top to bottom it is likely a cut height issue. If the bevel is only on 2 side and in the same direction it is likely a bad nozzle with an orifice that is no longer round.

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

Bevel is not on 4 sides, or 2 sides.weldguy wrote: Fri Oct 11, 2024 8:37 pm If your cutting a square and bevel is the same on all 4

sides for example tapered outwards from top to bottom or inwards from top to bottom it is likely a cut height issue. If the bevel is only on 2 side and in the same direction it is likely a bad nozzle with an orifice that is no longer round.

It is on 1 side at 8 degrees+, whereas the remaining 3 sides are below 3 degrees.

Just not the suggestions I'm looking for. I'm not new to this (and I know you aren't either, you have a good 13+years more experience than me at a minimum).

Consumables were swapped 3 times (including the swirl ring) so no it isn't a consumable issue at all as that would've showcased itself when the torch was rotated.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

Well you are understandably frustrated, I would say the next step is to see if Hypertherm will replace the torch. You don't have the old one ( I only just sold this torch last week).

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

I was sort of getting at that, when I inquired for technical assistance.acourtjester wrote: Fri Oct 11, 2024 10:05 pm Well you are understandably frustrated, I would say the next step is to see if Hypertherm will replace the torch. You don't have the old one ( I only just sold this torch last week).

They didn't say no, but are strongly implying no since "it is normal" and today's conversation took me back when John said "8 degrees is within range of what you should expect"

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

I think you will find many here will not agree with John, members who are using Hypertherm Plasma units. 3/8" steel on my DIY table Hypertherm 65 with Duramax torch.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

And I agree with you (and those other members you are referring to).acourtjester wrote: Fri Oct 11, 2024 10:25 pm I think you will find many here will not agree with John, members who are using Hypertherm Plasma units. 3/8" steel on my DIY table Hypertherm 65 with Duramax torch.

DSCN3179.JPG

DSCN3180.JPG

I still refuse to believe 8 degrees of beveling on one side is within tolerance, much less simply perform worse than a plasma cutter that costs less than a 3rd of the Hypertherm.

Only three solutions I have yet to try -

1. A different torch; I do have a hand torch so I may have to try that but would need to re-pin it to act like a machine torch

2. A different Hypertherm 45XP with my current machine torch; I can't justify buying a second Hypertherm machine for test purposes

3. A different table, utilizing either my machine and/or torch to rule out if the table itself is the issue even though it's been completely gone over

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

Buying another machine should not enter the picture, did you buy the Hypertherm from a local deal or online??

The hand torch may be a way to show if the machine torch has a problem. If you have a way to hook it on another table will surely remove many areas that may effect the cutting angle. You have a very odd problem with bevel only on one side.

The hand torch may be a way to show if the machine torch has a problem. If you have a way to hook it on another table will surely remove many areas that may effect the cutting angle. You have a very odd problem with bevel only on one side.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

Was semi-local.acourtjester wrote: Fri Oct 11, 2024 10:44 pm Buying another machine should not enter the picture, did you buy the Hypertherm from a local deal or online??

The hand torch may be a way to show if the machine torch has a problem. If you have a way to hook it on another table will surely remove many areas that may effect the cutting angle. You have a very odd problem with bevel only on one side.

Shop closed down, and the Hypertherm was new old stock (completely new, never used).

$1800 and it came with the $200 kit of consumables as well at no extra cost - not to worry I did buy the correct mechanized shield for my machine torch as the machine torch and CPC kit were purchased from Baker's Gas online.

Giving Hypertherm the serial number confirmed it's under warranty and even have my name to it per my case #, but the three different tech support specialists over the course of almost 2 months all conclude the machine is fine as well as the torch.

I forgot to add another thing. According to an old thread in here, someone ran into a similar issue and the answer was a new o-ring along with lubing it up.

I placed an order earlier this afternoon for a 5-pack of o-rings along with Hypertherm's own lubricant from Baker's Gas. I would've tried my local welding shops but both said they don't have them in stock. I do have o-rings I keep on hand for vehicles and the sort but didn't want to put in something not meant for plasma cutters.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

If you check this posting I have those "0" rings and will send you some for free, the grease is Hi dielectric and can be found in auto supply. storehttps://www.plasmaspider.com/viewtopic.php?f=60 ... gs#p227021

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

I couldn't source the smaller ones easily, at least not from the same source and would've had to look around.acourtjester wrote: Fri Oct 11, 2024 11:04 pm If you check this posting I have those "0" rings and will send you some for free, the grease is Hi dielectric and can be found in auto supply. storehttps://www.plasmaspider.com/viewtopic.php?f=60 ... gs#p227021

I'd love one/some of the smaller o-rings at the connector end, just to see if it helps.

Again, I came here after exhausting many options and this group is strictly plasma so hoping for something no one else has thought of (given the collective experience here).

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

sent a PM for your mailing address.

I'm hitting the sheets now.

I'm hitting the sheets now.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

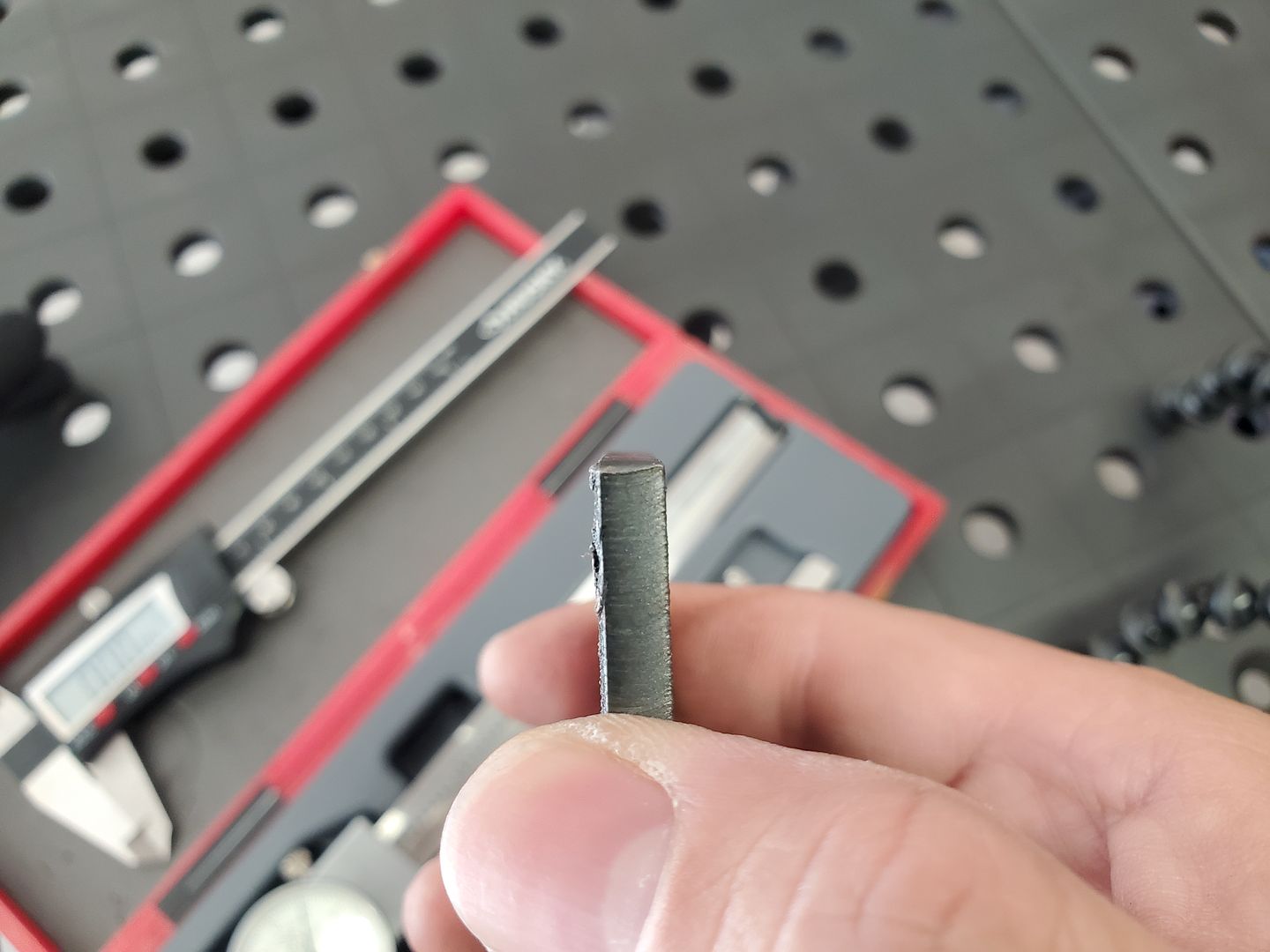

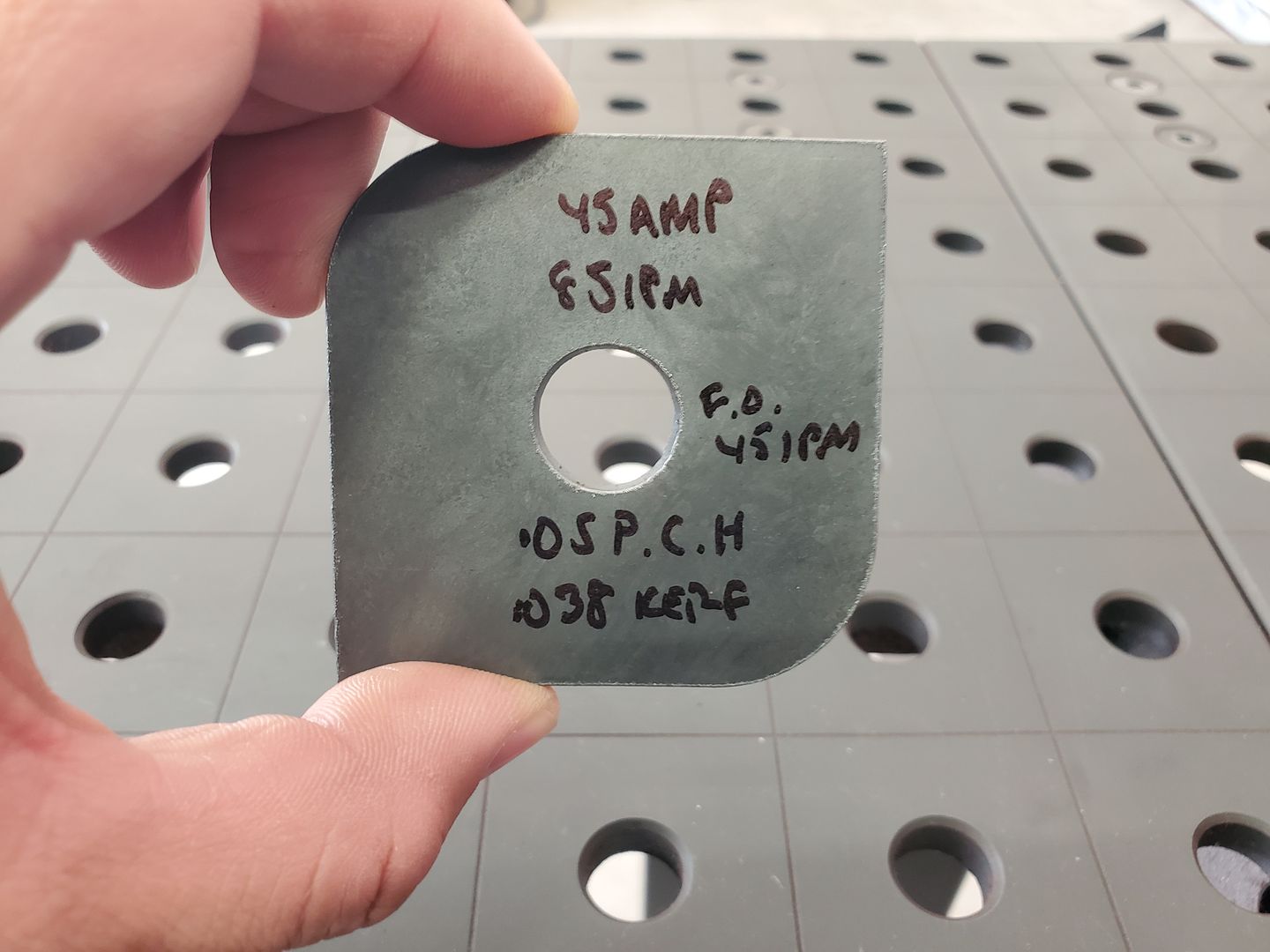

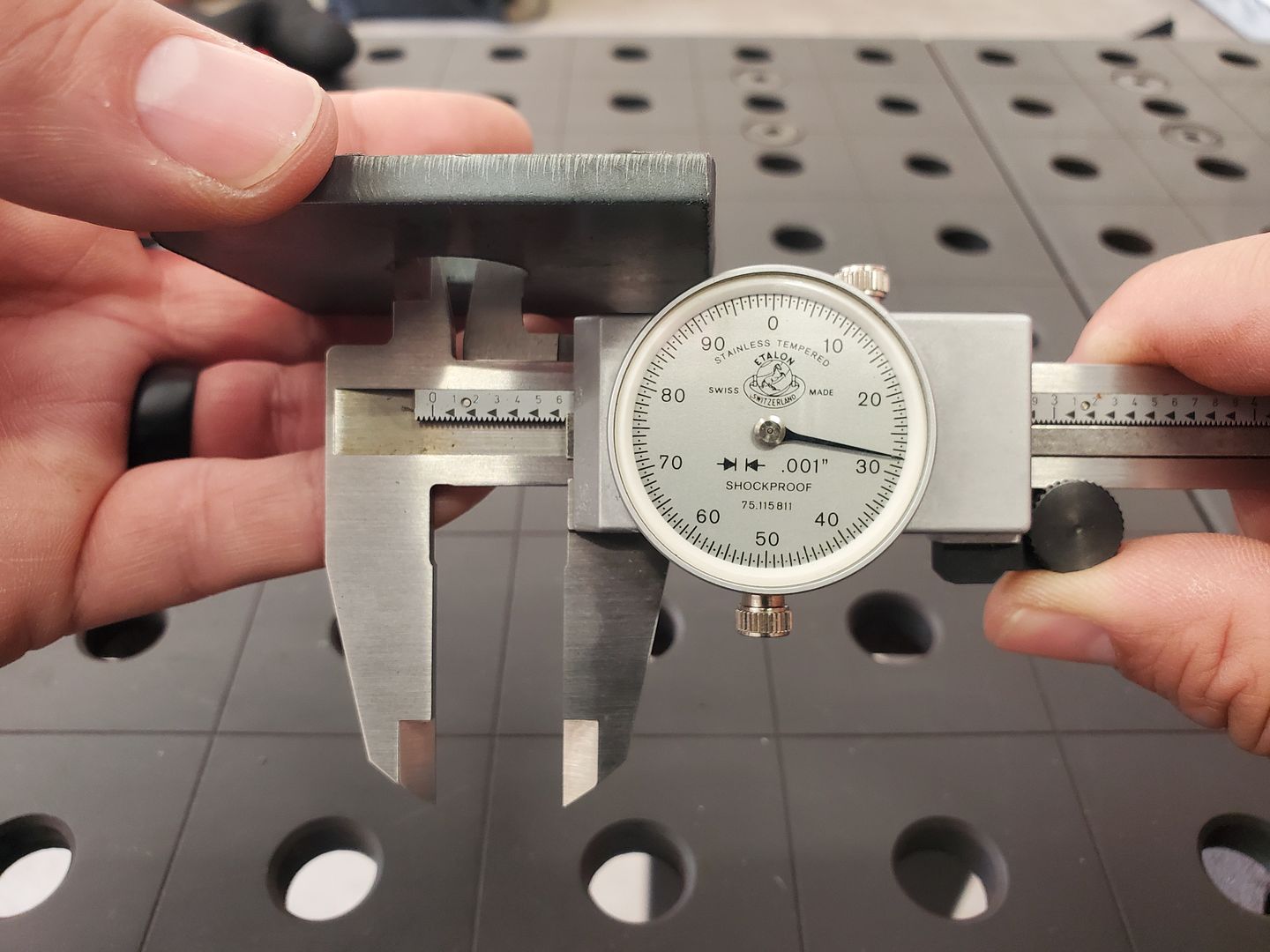

Looking forward to the o-rings on the way to me, but I went ahead and decided to use Sil Glyde on my torch head's o-ring and performed a few test cuts with no changes to anything else.

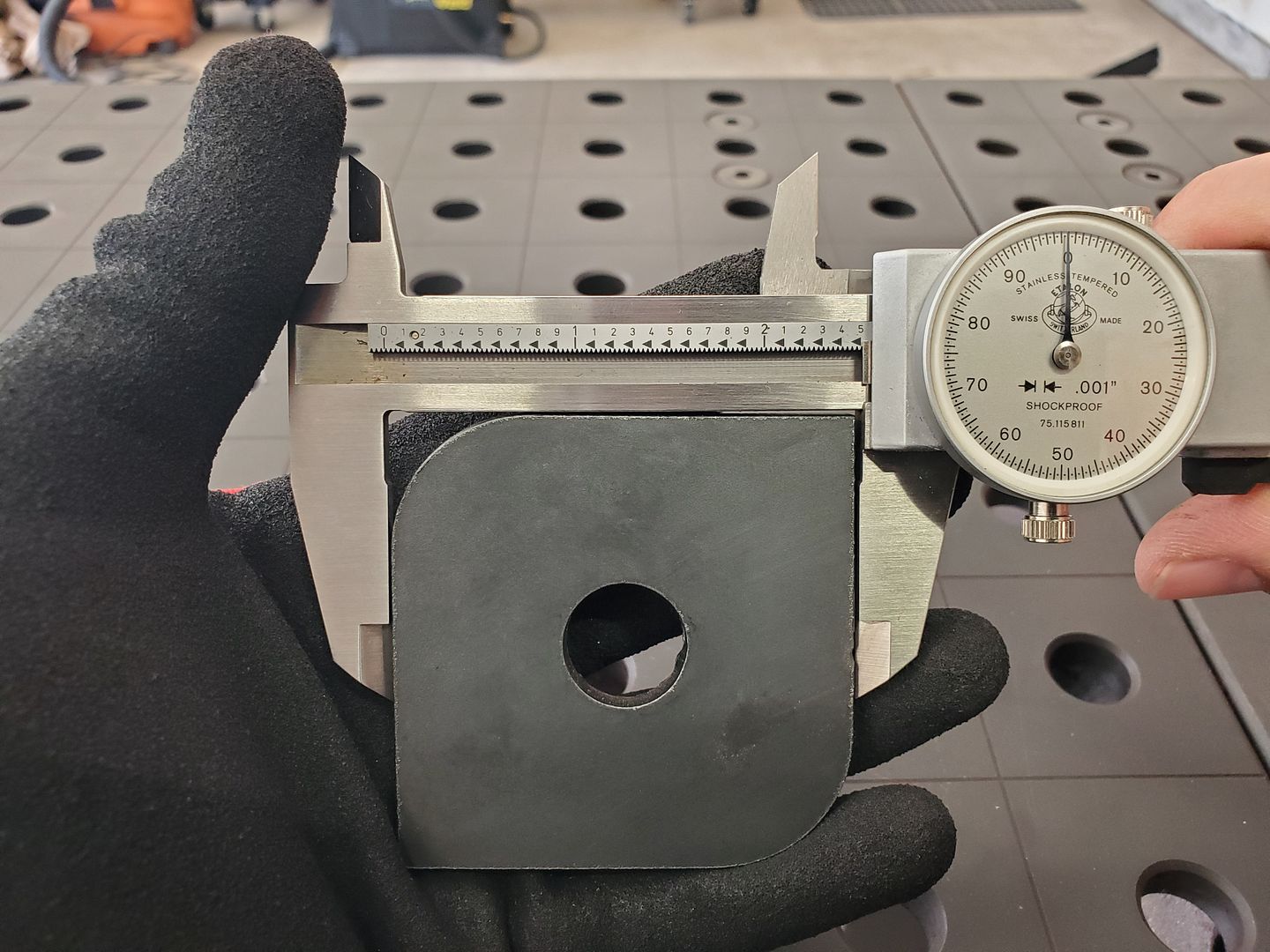

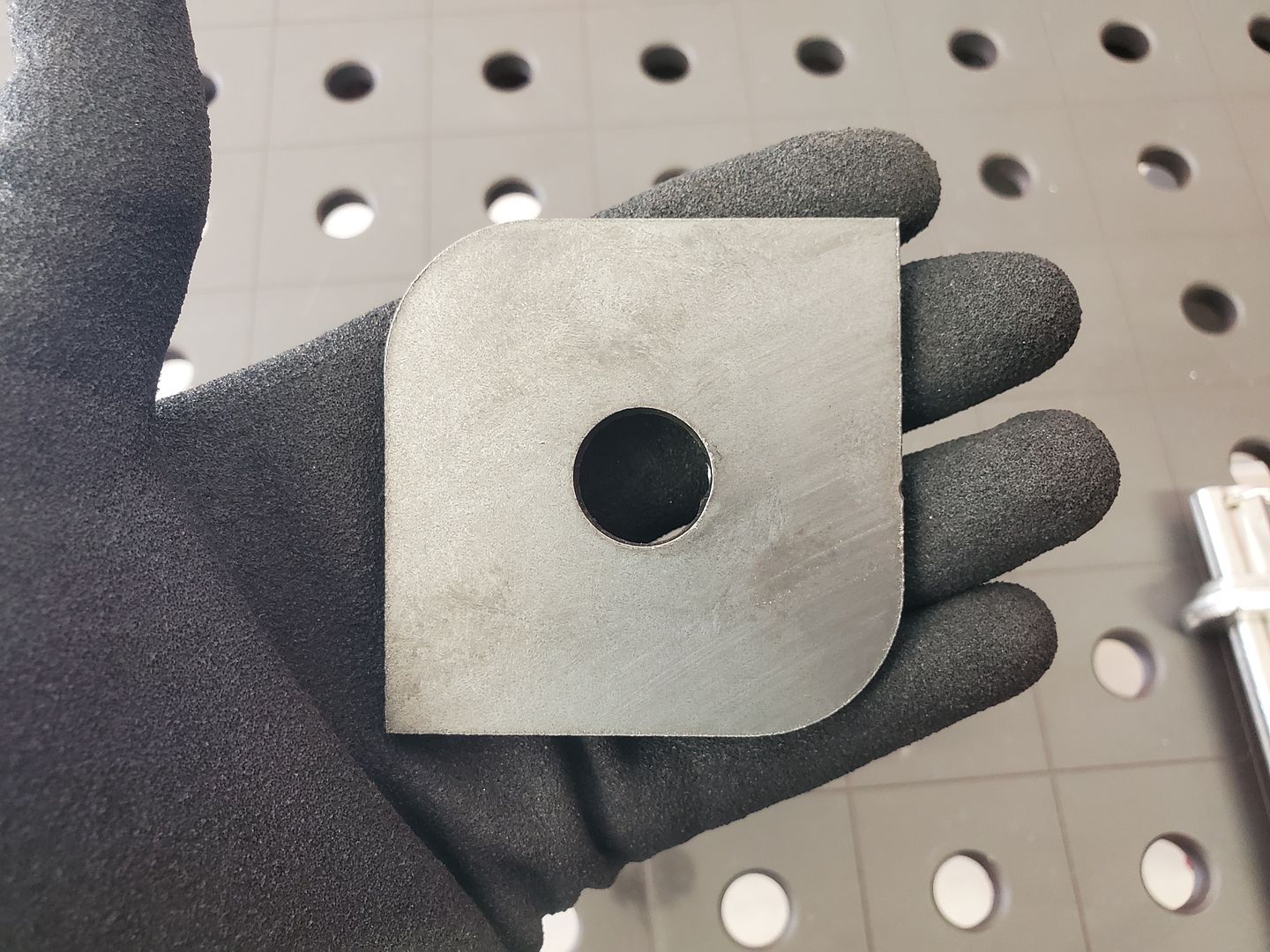

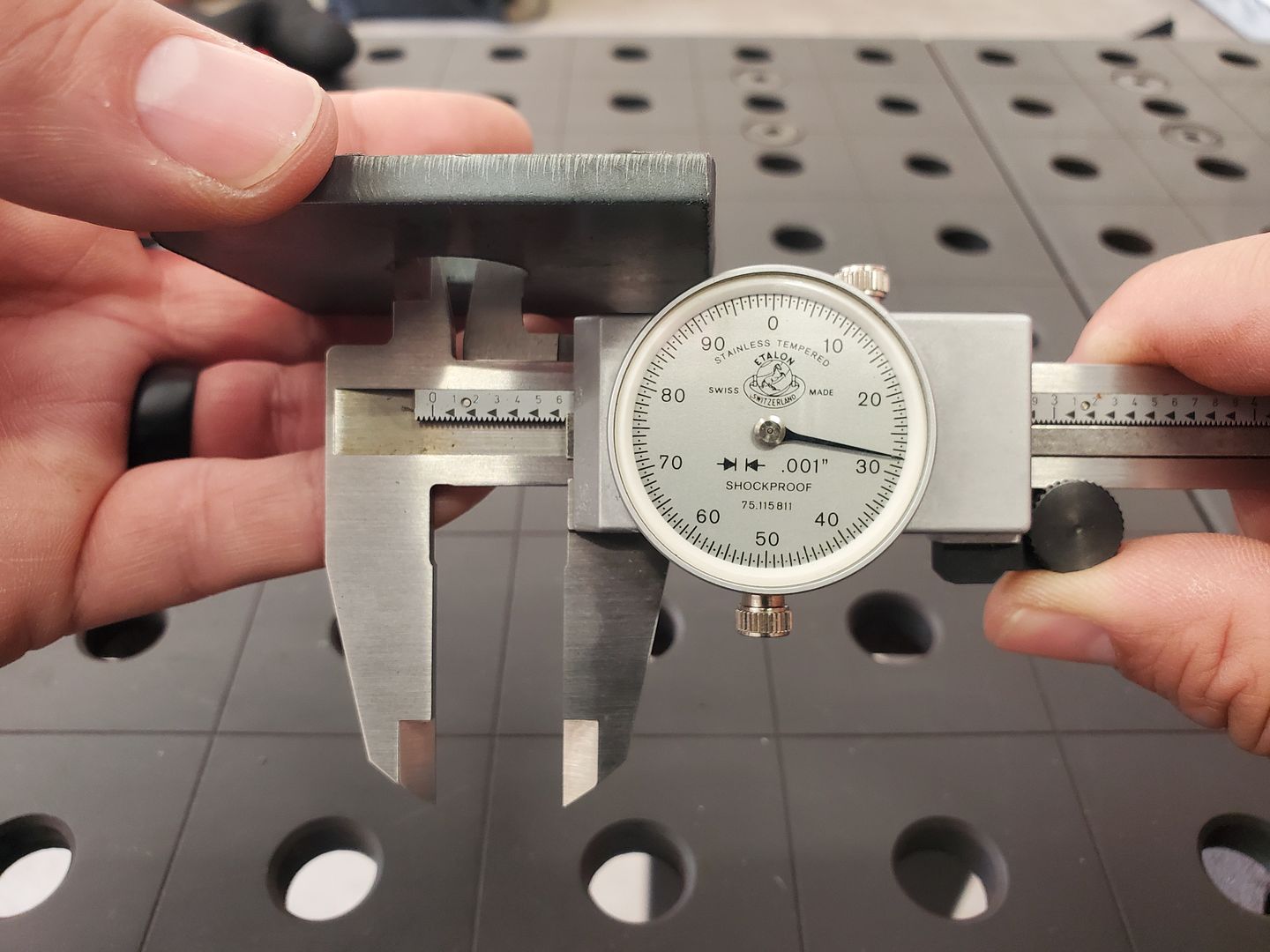

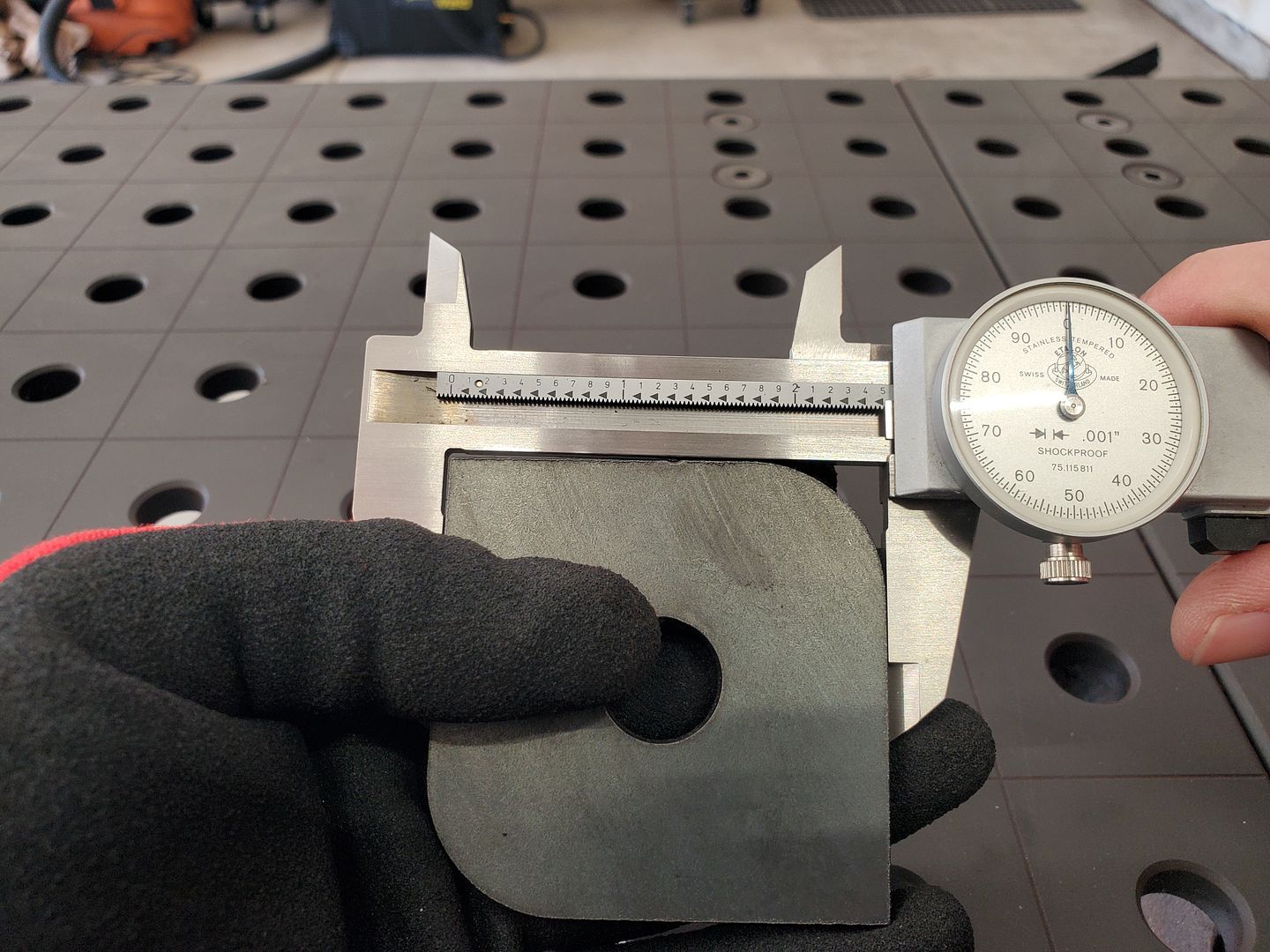

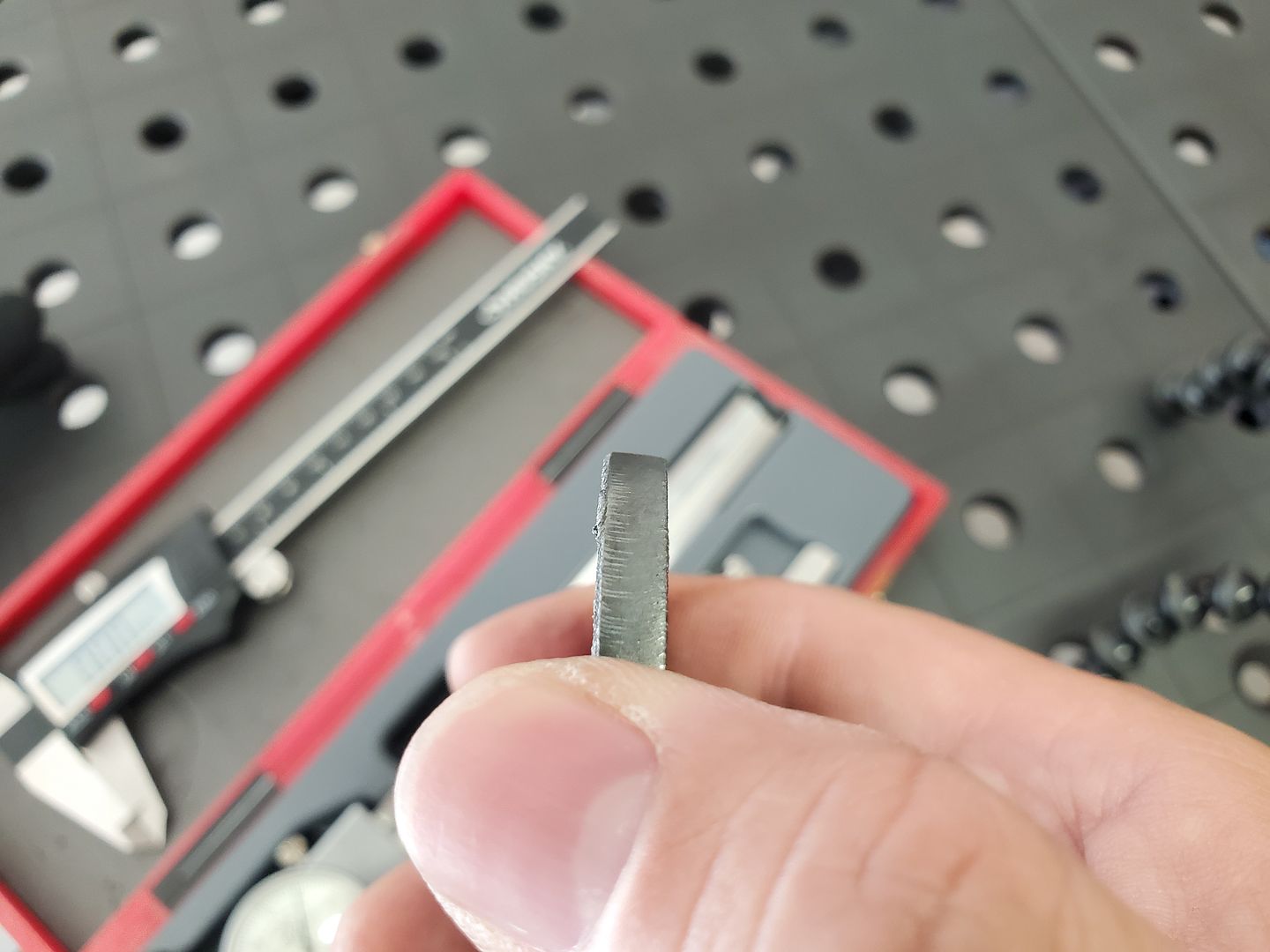

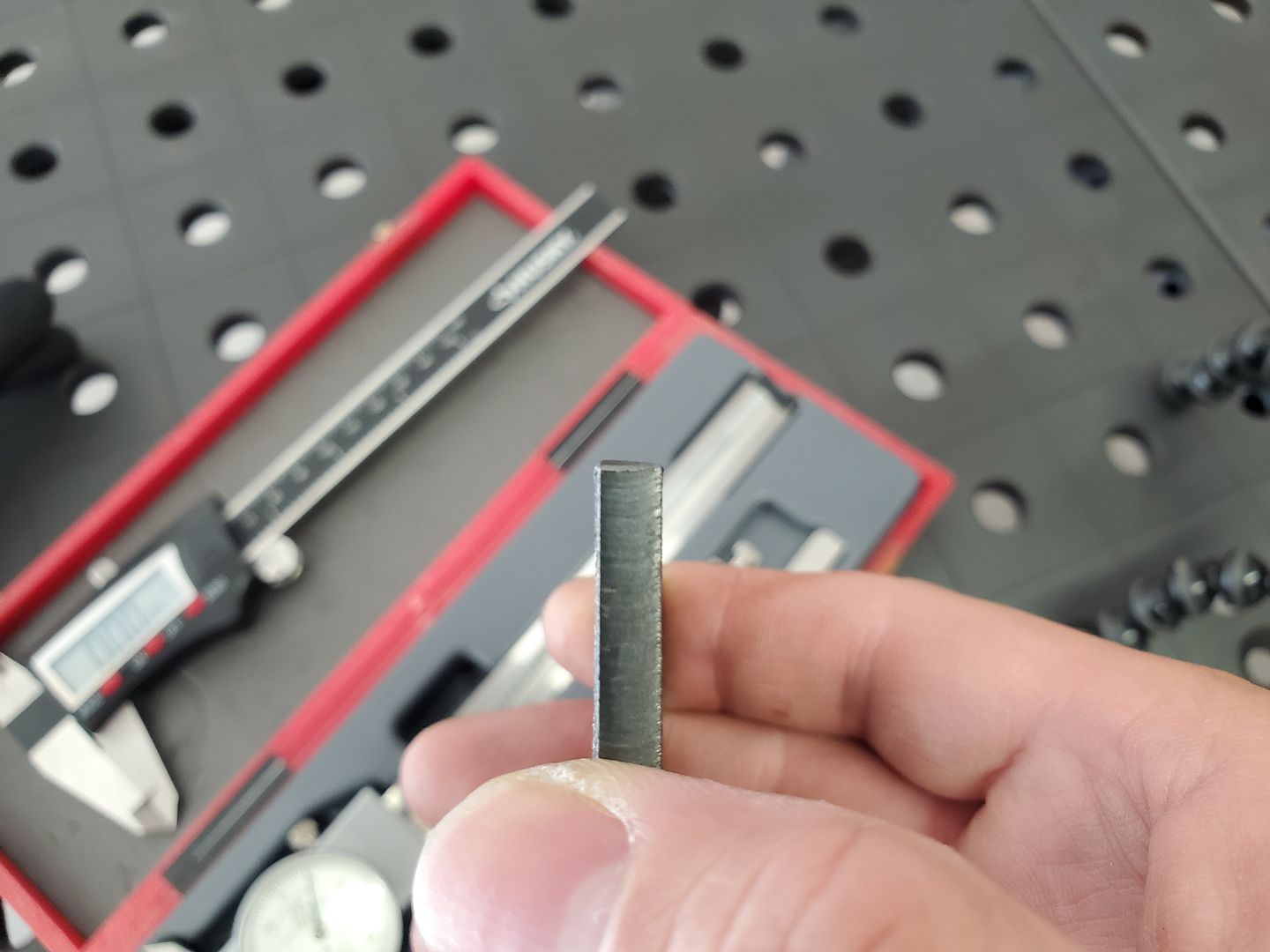

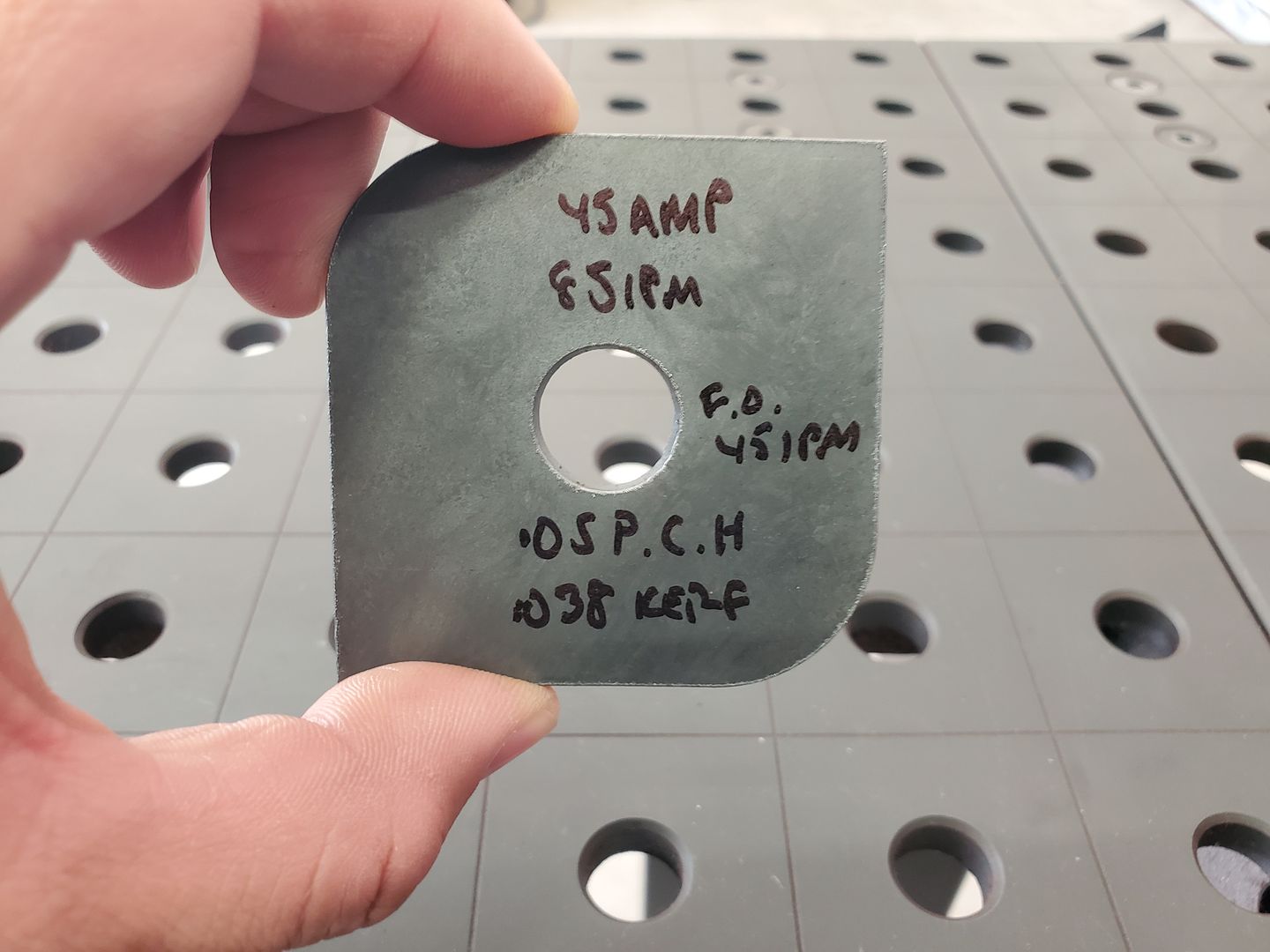

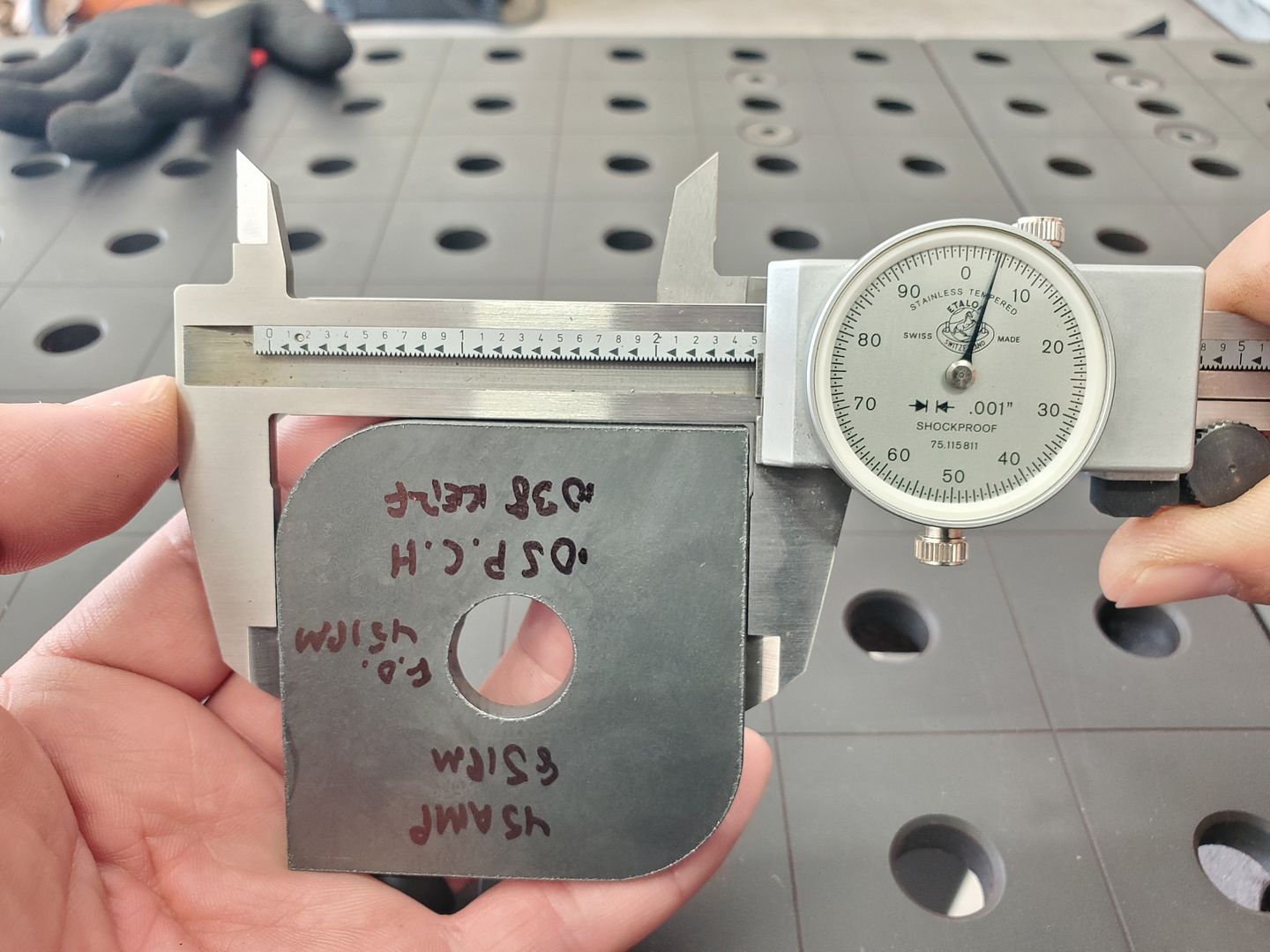

Two best cuts shown here, although I did some 7-8 cuts and all had similar results with the exception of the center hole (I made adjustments to my feed optimization until I found what gave me the best results).

The test pieces are a 2.5" x 2.5" square, with 0.75" radius on opposing corners, and a center hole with a 0.625" diameter - using Fusion 360 for CAD/CAM (been using this for the entire 2 years I've done CNC).

Outside dimensions were nearly dead on, I say nearly cause the lead-in/out didn't allow me to sit square with my calipers.

Tapering was non-existent but left me with a 0.645" hole, accidentally left FO at 25ipm.

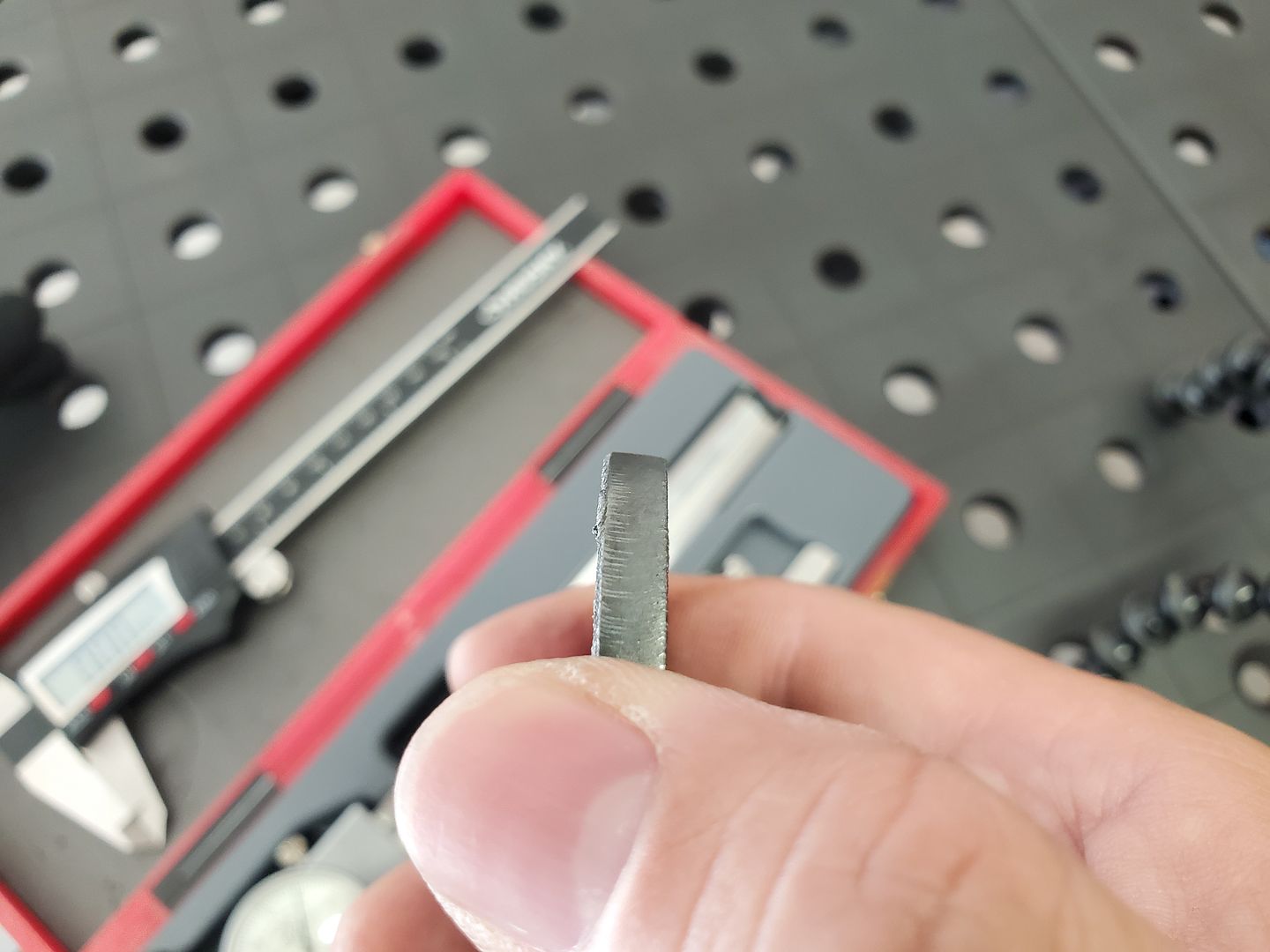

But, most importantly the bevel was nearly even all the way around at around 2-3 degrees. This is much more expected than the 8 degrees on the top-edge only I was getting before today.

I write on every piece I cut out, and the programmed cut height of .05" got me to a physical cut height of .06" which still gave me beveling all the way around but again, all within 2-3 degrees so I'll play with that later.

And with a feed optimization of 45ipm, the hole measures at 0.628"

I'm almost ruling this out as an o-ring issue.

Need to dial it in a tad whether it be speed and/or cut height but it is much better now.

Two best cuts shown here, although I did some 7-8 cuts and all had similar results with the exception of the center hole (I made adjustments to my feed optimization until I found what gave me the best results).

The test pieces are a 2.5" x 2.5" square, with 0.75" radius on opposing corners, and a center hole with a 0.625" diameter - using Fusion 360 for CAD/CAM (been using this for the entire 2 years I've done CNC).

Outside dimensions were nearly dead on, I say nearly cause the lead-in/out didn't allow me to sit square with my calipers.

Tapering was non-existent but left me with a 0.645" hole, accidentally left FO at 25ipm.

But, most importantly the bevel was nearly even all the way around at around 2-3 degrees. This is much more expected than the 8 degrees on the top-edge only I was getting before today.

I write on every piece I cut out, and the programmed cut height of .05" got me to a physical cut height of .06" which still gave me beveling all the way around but again, all within 2-3 degrees so I'll play with that later.

And with a feed optimization of 45ipm, the hole measures at 0.628"

I'm almost ruling this out as an o-ring issue.

Need to dial it in a tad whether it be speed and/or cut height but it is much better now.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11430

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Hypertherm 45XP - Single side bevel

Am I correct in assuming that lubricating your torch o-ring eliminated your previous problem with the large amount of taper on one side only? I have read over your last post several times and it seem like this improvement was the result of adding the Sil Glyde brake lubricant to your torch o-ring. If so, then my conclusion is that your torch was leaking around this o-ring and the lubrication sealed the leak. This was an unusual problem that I had not heard of before (taper on one side only), but am happy you have resolved your issue and hopefully this post may help other members who might encounter a similar problem in the future.

David

David

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

The thread I ran into suggested to the OP that he both install new o-rings as well as lube them as required. Mind you, his torch and setup were only about a year old.adbuch wrote: Sat Oct 12, 2024 8:27 pm Am I correct in assuming that lubricating your torch o-ring eliminated your previous problem with the large amount of taper on one side only? I have read over your last post several times and it seem like this improvement was the result of adding the Sil Glyde brake lubricant to your torch o-ring. If so, then my conclusion is that your torch was leaking around this o-ring and the lubrication sealed the leak. This was an unusual problem that I had not heard of before (taper on one side only), but am happy you have resolved your issue and hopefully this post may help other members who might encounter a similar problem in the future.

David

Since I don't have new o-rings in hand, I opted to use sil glyde as I use it for lubricating lots of different parts (like the o-rings on manual hubs).

The bevel is not completely gone, but has really evened out as you can see above.

I thought I was cutting at the correct torch height after I got a better cut - I'm using CAD programming for cut height versus voltage since it's 3/16" and I don't need to worry about springback when the torch touches off the metal. A cut height of .06" has been established so I think now I just need to work on my cut speed by slowing it down a hair. In theory, that should help bevel a bit more but I'm all out of 3/16" for test purposes.

All that's next is to run my production of parts on 3/16" to see if repeatability occurs.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11430

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Hypertherm 45XP - Single side bevel

Thanks for the update! Good luck with your production run.

David

David

- tinspark

- 3.5 Star Elite Contributing Member

- Posts: 801

- Joined: Wed May 30, 2018 4:28 pm

Re: Hypertherm 45XP - Single side bevel

I have an entire small box of test cuts all with beveling that occurs on the top edge. Regardless of where my start point is on the piece, regardless of where on the table it is cut from.

I am just not completely convinced that my Hypertherm should cut worse than my PrimeWeld.

[/quote]

Sorry if my response is redundant. I did not have time to read all of the posts or eve all of this post. I saw a few pictures and the bevel issue.

I have had great success with the same cutter, but.......

Based on the pictures I saw, it looks like it may be a height issue.

I dont trust my machine settings. I manually set my height up after I input the book specs into my software.

The plasma arc is shaped like a human eye turned sideways (elongated) see picture. The higher the torch head, the more that the eye is raised and bevel a bevel is cut.

I stop my test cut before it is finished with the cut (usually just 8"-12" long line cuts) and slide a piece of 16 gauge (.06-ish thick) between the nozzle to check the ACTUAL cut height then make adjustments manually.

My controller says its set at a certain height, and it lies to me all of the time.

the torch is often either dragging on the sheet or up at about 1/8". I am actuall surprised when my THC is set correctly the first time.

I will lower the torch heed and subsequently the plasmastream (eye) and gives me a lot less bevel. The trick is to be about in the center of the eye. which should be book spec.. see picture.

I do this EVERY time I fire up my machine. And after I am stisfied that it is set and I start cutting jobs out, I will often stop a cut mid job and check it . Once it is set, I am usually good to go for the day. But as the hafniumm wears in the electrode, an operator would need to account for that and lower the torch head more as indicated by a bevel showing up later, and a pitted electrod, which is normal up to a point. Hope U figuret it out!

I am just not completely convinced that my Hypertherm should cut worse than my PrimeWeld.

[/quote]

Sorry if my response is redundant. I did not have time to read all of the posts or eve all of this post. I saw a few pictures and the bevel issue.

I have had great success with the same cutter, but.......

Based on the pictures I saw, it looks like it may be a height issue.

I dont trust my machine settings. I manually set my height up after I input the book specs into my software.

The plasma arc is shaped like a human eye turned sideways (elongated) see picture. The higher the torch head, the more that the eye is raised and bevel a bevel is cut.

I stop my test cut before it is finished with the cut (usually just 8"-12" long line cuts) and slide a piece of 16 gauge (.06-ish thick) between the nozzle to check the ACTUAL cut height then make adjustments manually.

My controller says its set at a certain height, and it lies to me all of the time.

the torch is often either dragging on the sheet or up at about 1/8". I am actuall surprised when my THC is set correctly the first time.

I will lower the torch heed and subsequently the plasmastream (eye) and gives me a lot less bevel. The trick is to be about in the center of the eye. which should be book spec.. see picture.

I do this EVERY time I fire up my machine. And after I am stisfied that it is set and I start cutting jobs out, I will often stop a cut mid job and check it . Once it is set, I am usually good to go for the day. But as the hafniumm wears in the electrode, an operator would need to account for that and lower the torch head more as indicated by a bevel showing up later, and a pitted electrod, which is normal up to a point. Hope U figuret it out!

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Last edited by tinspark on Sun Oct 13, 2024 5:08 pm, edited 1 time in total.

Doug,

4x4 GoTorch- expanded

Height Control/Advanced DesignEdge

Hypertherm 45XP-

Logan Lathe + myriads of other shop toys

**CAUTION**- "Does Not Play Well With Others"

4x4 GoTorch- expanded

Height Control/Advanced DesignEdge

Hypertherm 45XP-

Logan Lathe + myriads of other shop toys

**CAUTION**- "Does Not Play Well With Others"

- tinspark

- 3.5 Star Elite Contributing Member

- Posts: 801

- Joined: Wed May 30, 2018 4:28 pm

Re: Hypertherm 45XP - Single side bevel

here is a better picture. it shows the bevel effect of either too high or too low, and the sweet spot.

also, based on your bevel flaring out from top of sheet to bottom af sheet, it looks like you may need to lower your cut height after performing a "test line cut" or two as mentioned in my earlier post.

also, based on your bevel flaring out from top of sheet to bottom af sheet, it looks like you may need to lower your cut height after performing a "test line cut" or two as mentioned in my earlier post.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Last edited by tinspark on Sun Oct 13, 2024 3:22 pm, edited 1 time in total.

Doug,

4x4 GoTorch- expanded

Height Control/Advanced DesignEdge

Hypertherm 45XP-

Logan Lathe + myriads of other shop toys

**CAUTION**- "Does Not Play Well With Others"

4x4 GoTorch- expanded

Height Control/Advanced DesignEdge

Hypertherm 45XP-

Logan Lathe + myriads of other shop toys

**CAUTION**- "Does Not Play Well With Others"

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8525

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hypertherm 45XP - Single side bevel

Here is a video on how to check your torch height and the THC voltage setting. May be a different brand but the method is the same.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Kwikvette

- 1.5 Star Member

- Posts: 39

- Joined: Sun Aug 20, 2023 2:34 am

Re: Hypertherm 45XP - Single side bevel

Hey Tin, there's nothing wrong with skipping the majority of the post..it's rather lengthy and it's rather frustrating for me to constantly repeat it to no avail but I'll add this -tinspark wrote: Sun Oct 13, 2024 2:57 pm

Sorry if my response is redundant. I did not have time to read all of the posts or eve all of this post. I saw a few pictures and the bevel issue.

I have had great success with the same cutter, but.......

Based on the pictures I saw, it looks like it may be a height issue.

I dont trust my machine settings. I manually set my height up after I input the book specs into my software.

The plasma arc is shaped like a human eye turned sideways (elongated) see picture. The higher the torch head, the more that the eye is raised and bevel a bevel is cut.

I stop my test cut before it is finished with the cut (usually just 8"-12" long line cuts) and slide a piece of 16 gauge (.06-ish thick) between the nozzle to check the ACTUAL cut height then make adjustments manually.

My controller says its set at a certain height, and it lies to me all of the time.

the torch is often either dragging on the sheet or up at about 1/8". I am actuall surprised when my THC is set correctly the first time.

I will lower the torch heed and subsequently the plasmastream (eye) and gives me a lot less bevel. The trick is to be about in the center of the eye. which should be book spec.. see picture.

I do this EVERY time I fire up my machine. And after I am stisfied that it is set and I start cutting jobs out, I will often stop a cut mid job and check it . Once it is set, I am usually good to go for the day. But as the hafniumm wears in the electrode, an operator would need to account for that and lower the torch head more as indicated by a bevel showing up later, and a pitted electrod, which is normal up to a point. Hope U figuret it out!

I have been doing this for awhile, and what you are sharing is exactly how I help other people set their torch height.

Like you, I too do not trust what is on the screen. Which is why my last test piece says ".05 PCH" which stands for .05" programmed cut height.

In order to achieve a .06" physical cut height, there is a .01" deviation on my programming hence I post process my files with a programmed height for .05". I use feeler gauges to physically measure and have done this since day 1.

You are much better at it though, checking as often as you do. I would check it about once a week to ensure everything runs as it should.

I was just hoping the very first pics of my parts (that display between 1-2 degrees of bevel) would be enough to satisfy people that I do know how to set up my table. It's been running flawlessly for 2 years and the 8 degree beveling only occurred when I got the new Hypertherm.