I also attached the DXF file I have so far after tracing.

Novice here, Please Help

-

Splinters&Sparx

- 1 Star Member

- Posts: 18

- Joined: Fri Apr 28, 2023 3:09 pm

Novice here, Please Help

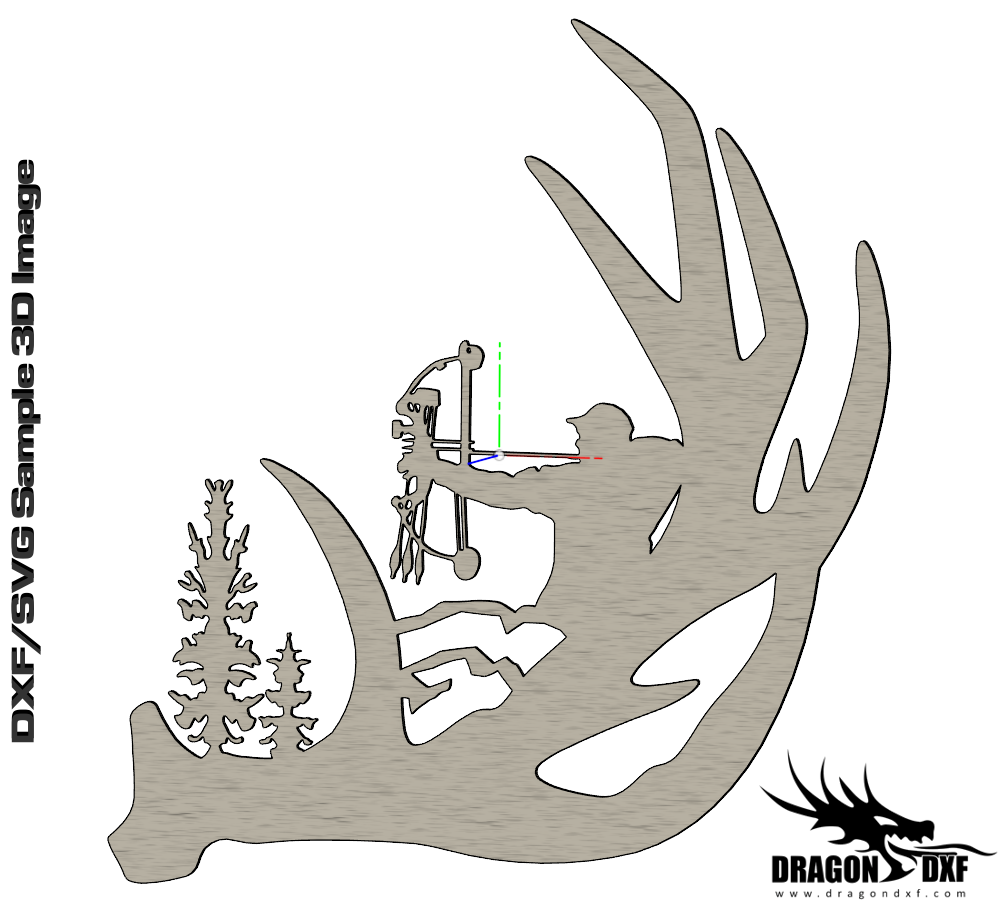

I am going crazy trying to figure out how to design this image to cut. I use Aspire, I have traced it, converted it to DXF, but when I look at it to fix lines and areas to keep or fall out I am at a loss. I haven't been doing this long so I appreciate any tips I can get. I will pay someone to teach me this, I am desperate  . The sign is supposed to be 24" H after its cut. Thank ya'll in advance.

. The sign is supposed to be 24" H after its cut. Thank ya'll in advance.

I also attached the DXF file I have so far after tracing.

I also attached the DXF file I have so far after tracing.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

- Larry83301

- 5 Star Elite Contributing Member

- Posts: 2610

- Joined: Tue Oct 27, 2009 6:36 pm

- Location: Twin Falls, Idaho

Re: Novice here, Please Help

Pictures like that don't do very well as a flat pieces. I would make it several layers starting with the collar and ending with the nose and teeth. The horns could be part of the first layer with the helmet cut to show the horn on the right. The dark part of the cheek would be part of this back layer also. That's just me but I do many pieces as two or three and some tims four layers makes them stand out.

Larry

Larry

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

plasmanewbie

- 5 Star Elite Contributing Member

- Posts: 2867

- Joined: Thu Jul 24, 2008 11:15 am

Re: Novice here, Please Help

Opened your dxf and I would say your trace looks pretty darn good. Definately a lot of bridges to make to hold things together if you wanted to cut it all 1 piece! Larry's right it would be best to do this as multi layer sign, you could almost cut all the components out as it sits and just use and epoxy or something to bond all the components to the main background.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8489

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Novice here, Please Help

I agree with the above post, Your trace is very good but I would separate the parts and cut them as layers for a finished item. You will loose to much detail and have a hard time coloring as a single layer. Attached are 3 different project I did showing what we are talking about. Also the medallion on the collar will be real hard. You have done most of the work with the trace, it is fairly easy to separate the parts and generate a cut plan.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8489

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Novice here, Please Help

this is similar to what I am talking about, there are parts that are open lines that will need to be connected in you trace.

I use Inkscape to these thing and have different pages open to separate copy and paste the parts around to complete the cut plan.

I use Inkscape to these thing and have different pages open to separate copy and paste the parts around to complete the cut plan.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8489

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Novice here, Please Help

video of the cutting process for the gator.

https://drive.google.com/file/d/1GlX5Cy ... sp=sharing

https://drive.google.com/file/d/1GlX5Cy ... sp=sharing

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11227

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Novice here, Please Help

PM Sent. Check your private messages.Splinters&Sparx wrote: Fri Oct 13, 2023 9:12 am I am going crazy trying to figure out how to design this image to cut. I use Aspire, I have traced it, converted it to DXF, but when I look at it to fix lines and areas to keep or fall out I am at a loss. I haven't been doing this long so I appreciate any tips I can get. I will pay someone to teach me this, I am desperate. The sign is supposed to be 24" H after its cut. Thank ya'll in advance.

I also attached the DXF file I have so far after tracing.

- Joe Jones

- 5 Star Elite Contributing Member

- Posts: 3781

- Joined: Sat Oct 11, 2014 2:33 pm

- Location: Franklin, KY., USA

- Contact:

Re: Novice here, Please Help

A design with multiple colors cannot easily be cut out if a single layer of media. It is possible, but you are talking about a LOT of custom drawing time to make puzzle pieces, each individually cut out and taking kerf width and other factors into consideration.Splinters&Sparx wrote: Fri Oct 13, 2023 9:12 am I am going crazy trying to figure out how to design this image to cut.

Since a plasma cutter has a wide kerf width as compared to a laser or any other extremely fine cutting process, in order to fit one piece into another with a tight tolerance, you would need to cut them out separately. For example, you could not get a tight fit by cutting a 2"x2" square out of a 4"x4"inch square. However, you could cut a 2"x2" square out of material, and then cut a 4"x4" square with a 2"x2" hole in the center. It would be necessary to clearance the corners of the hole for a tight fit, since the plasma cut interior corner is round, and the external corner of the 2"x2" square is square.

Layering is another option, that allows for a more interesting, dimensional product, but layers of steel are heavy.

The third option is to cut the profile out of steel, and have the art PRINTED and applied to the steel outline like a sticker. Images that are printed are 2D, and plasma cutting is 3D. you cannot cross over from one to the other, without making some compromises.

Joe

FREE DesignEdge Training Online Via ZOOM!

PlasmaCam 4x4 and 5x10 w/ ALL Upgrades

(14) X-TOOL LASERS

LaserPecker 1 PRO, LP-2, LP-4 + accs

50 Watt GALVO fiber

TYVOK Spider S1 60W Diode Laser 49" x 96"

1,000 Watt 4x8 Fiber Laser Table

(2) X-TOOL Apparel Printers

(2) XTOOL MetalFab Machines

CreatBot D600 PRO

Fortus 400mc

BIGREP Studio Gen 2

MODIX Big Meter

MakerBOT Z-18 3D Printer

Bernardo Mach 55 TON Ironworker

Grizzly G0792 - Roll Bender

Langmuir MR-1 CNC Mill

PlasmaCam 4x4 and 5x10 w/ ALL Upgrades

(14) X-TOOL LASERS

LaserPecker 1 PRO, LP-2, LP-4 + accs

50 Watt GALVO fiber

TYVOK Spider S1 60W Diode Laser 49" x 96"

1,000 Watt 4x8 Fiber Laser Table

(2) X-TOOL Apparel Printers

(2) XTOOL MetalFab Machines

CreatBot D600 PRO

Fortus 400mc

BIGREP Studio Gen 2

MODIX Big Meter

MakerBOT Z-18 3D Printer

Bernardo Mach 55 TON Ironworker

Grizzly G0792 - Roll Bender

Langmuir MR-1 CNC Mill

- Joe Jones

- 5 Star Elite Contributing Member

- Posts: 3781

- Joined: Sat Oct 11, 2014 2:33 pm

- Location: Franklin, KY., USA

- Contact:

Re: Novice here, Please Help

This image has 16 different colors. It is not well suited for plasma cutting. You could use a router for solid material, but this image is better suited for a vinyl cutter or a printed process.Splinters&Sparx wrote: Fri Oct 13, 2023 9:12 am I am going crazy trying to figure out how to design this image to cut.

Joe

FREE DesignEdge Training Online Via ZOOM!

PlasmaCam 4x4 and 5x10 w/ ALL Upgrades

(14) X-TOOL LASERS

LaserPecker 1 PRO, LP-2, LP-4 + accs

50 Watt GALVO fiber

TYVOK Spider S1 60W Diode Laser 49" x 96"

1,000 Watt 4x8 Fiber Laser Table

(2) X-TOOL Apparel Printers

(2) XTOOL MetalFab Machines

CreatBot D600 PRO

Fortus 400mc

BIGREP Studio Gen 2

MODIX Big Meter

MakerBOT Z-18 3D Printer

Bernardo Mach 55 TON Ironworker

Grizzly G0792 - Roll Bender

Langmuir MR-1 CNC Mill

PlasmaCam 4x4 and 5x10 w/ ALL Upgrades

(14) X-TOOL LASERS

LaserPecker 1 PRO, LP-2, LP-4 + accs

50 Watt GALVO fiber

TYVOK Spider S1 60W Diode Laser 49" x 96"

1,000 Watt 4x8 Fiber Laser Table

(2) X-TOOL Apparel Printers

(2) XTOOL MetalFab Machines

CreatBot D600 PRO

Fortus 400mc

BIGREP Studio Gen 2

MODIX Big Meter

MakerBOT Z-18 3D Printer

Bernardo Mach 55 TON Ironworker

Grizzly G0792 - Roll Bender

Langmuir MR-1 CNC Mill

-

Splinters&Sparx

- 1 Star Member

- Posts: 18

- Joined: Fri Apr 28, 2023 3:09 pm

Re: Novice here, Please Help

Thank ya'll so much I really appreciate all of the advice

Download Design

Download Design