Brad.

Mill Conversion to Plasma cutter.

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Mill Conversion to Plasma cutter.

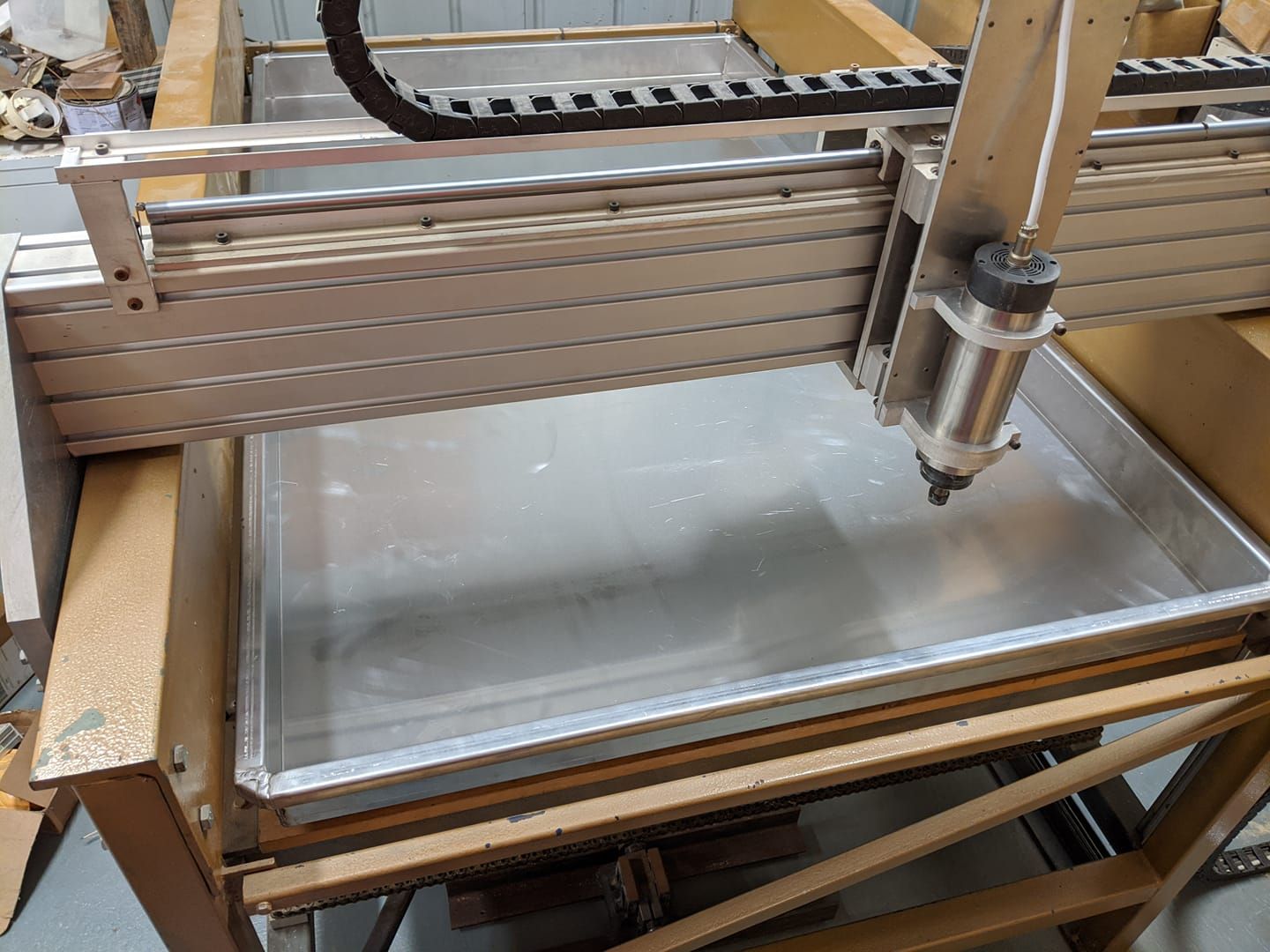

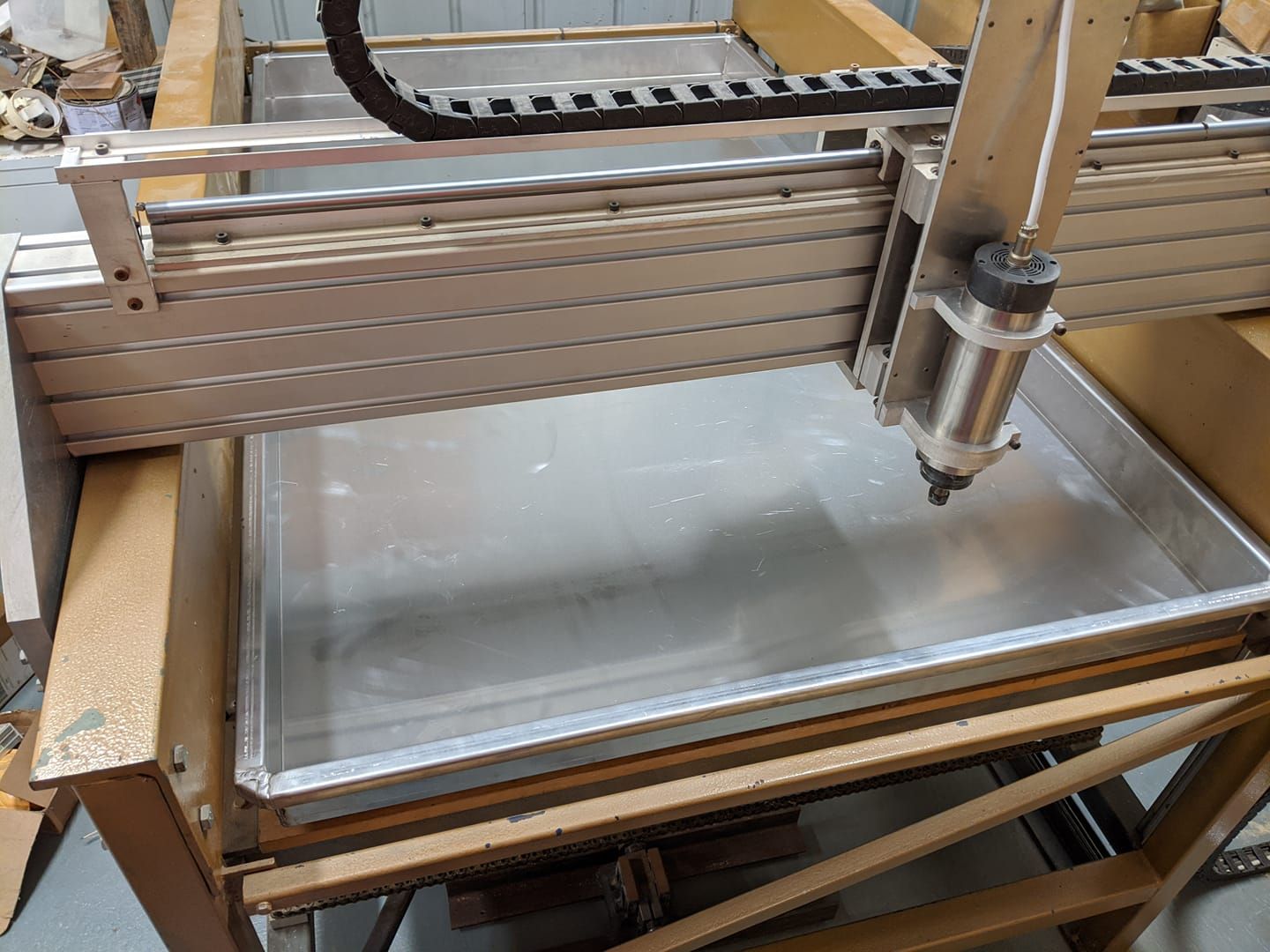

I just finished the addition of plasma cutting to my mill set up. The water tray will slide off the back of the mill and spindle can quickly be swapped back in. Here's my first cut. Im pretty happy with it.

Brad.

Brad.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

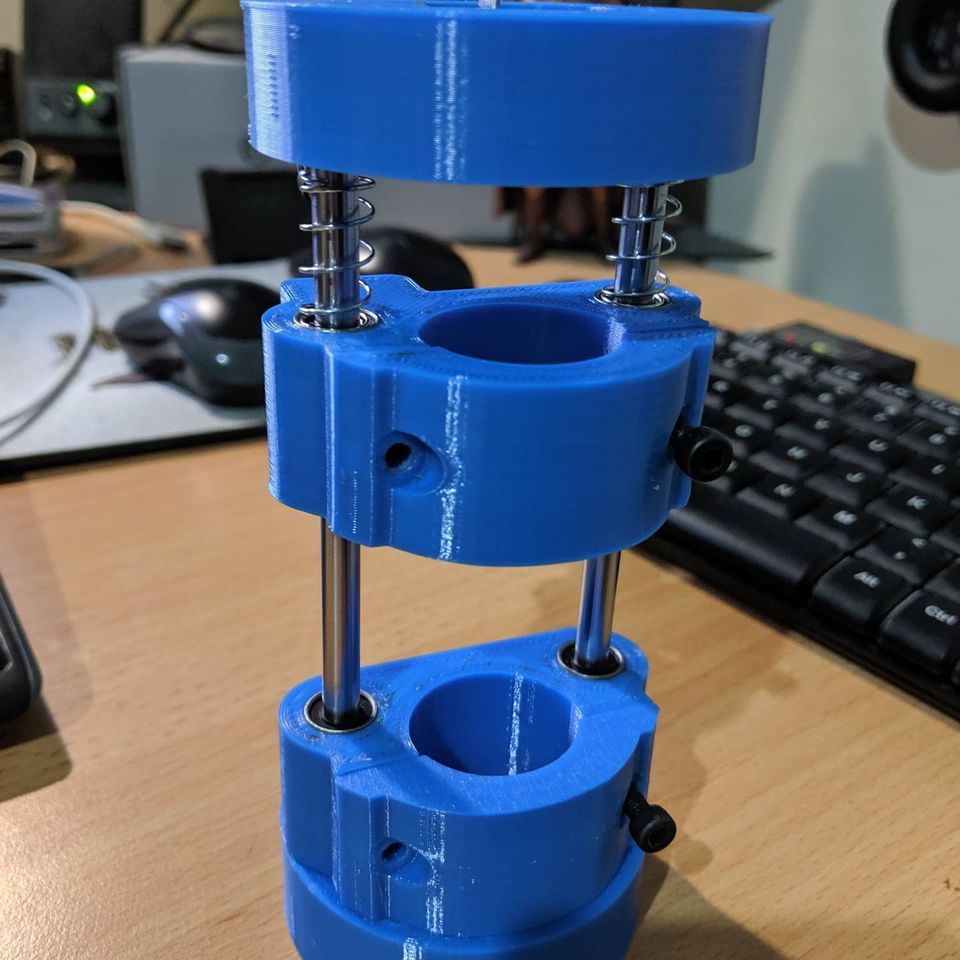

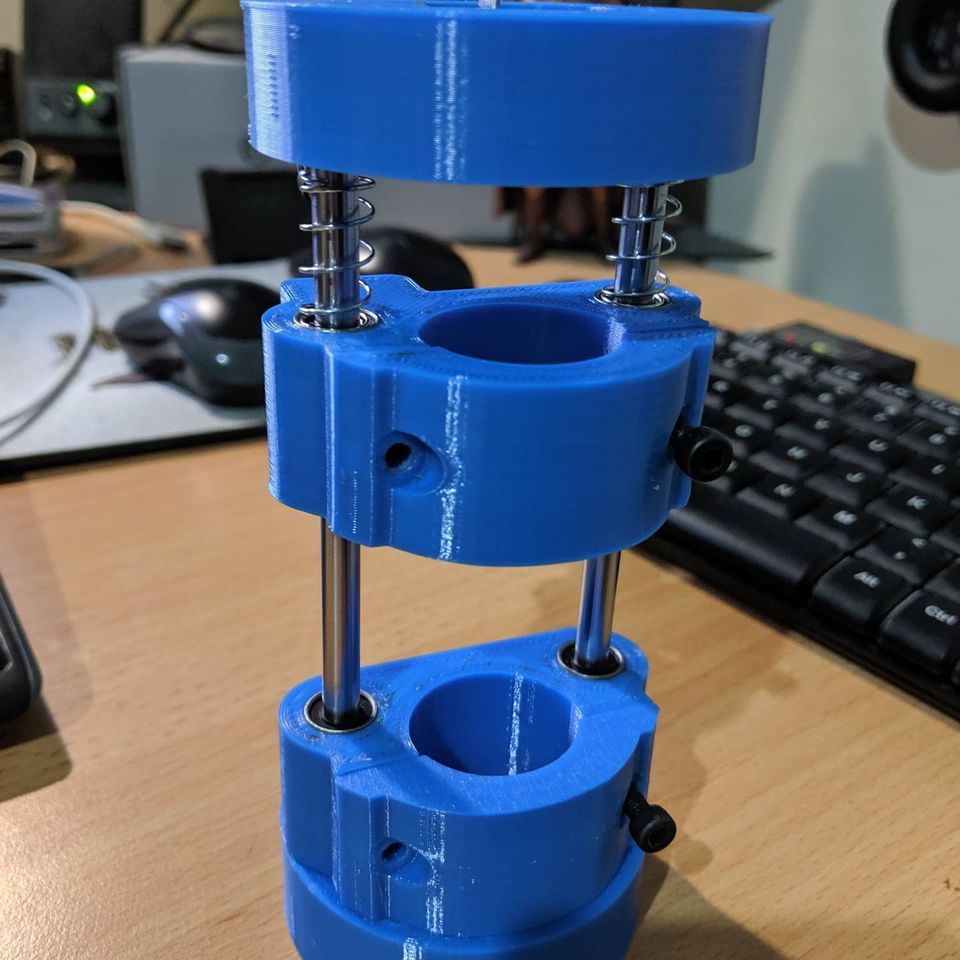

Well I say it will do the job,  great start and for learning more about Plasma cutting. Start lining up the new projects to do and Looks like a little 3-D printing involved too.

great start and for learning more about Plasma cutting. Start lining up the new projects to do and Looks like a little 3-D printing involved too.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11433

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Mill Conversion to Plasma cutter.

Hi Brad,

What kind of "mill" is that? What materials do you normally machine? Do you have more photos showing the spindle you use for machining? I checked your Youtube channel, but didn't see any other videos of your "mill".

Thanks,

David

What kind of "mill" is that? What materials do you normally machine? Do you have more photos showing the spindle you use for machining? I checked your Youtube channel, but didn't see any other videos of your "mill".

Thanks,

David

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

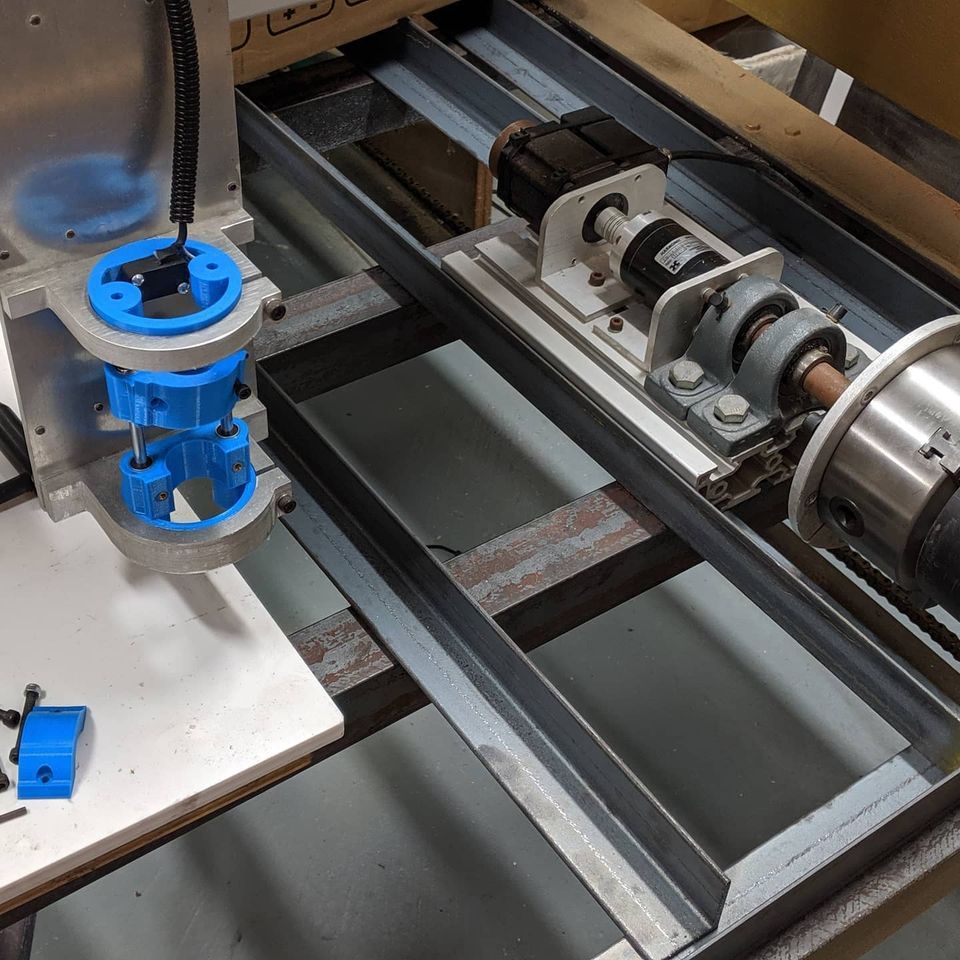

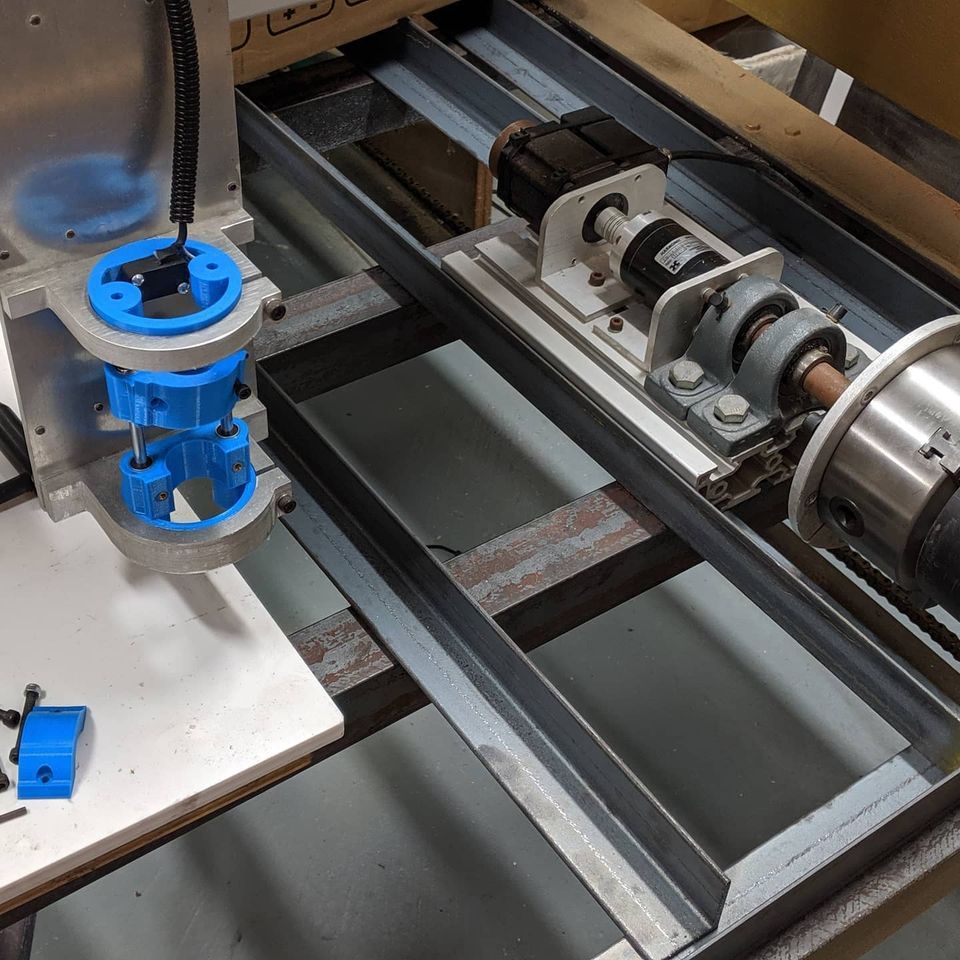

Here's some milling.

My mill is home made.1260mm x 860mm. Z axis range is about 380mm. My table sits on 4 allthread rods so I can raise and lower it in set up depending on the job. Mostly it sits at the top. You can see the chain in the pic below that rotates the allthread rods. Spindle is 1.5kw air cooled. Plasma cutter is a lotos ltp5000. Hypertherms are $3000 here in Australia. Can't afford that!! I use a G540 in a metal box with ferrites on all wires entering the control box. The frame of the mill is independently earth outside my workshop. I have switched off the limit switches in the Mach3 plasma profile I set up as the EMI was tripping them when I was doing test air cuts, but the pilot arc was continually firing so EMI would have been very high.

I took the wooden surface off my table, but put it back on again as I needed to mill a job. I've decided to just leave it on there and sit the water tray on top as it pretty much covers it so shouldnt get wet.

My mill is home made.1260mm x 860mm. Z axis range is about 380mm. My table sits on 4 allthread rods so I can raise and lower it in set up depending on the job. Mostly it sits at the top. You can see the chain in the pic below that rotates the allthread rods. Spindle is 1.5kw air cooled. Plasma cutter is a lotos ltp5000. Hypertherms are $3000 here in Australia. Can't afford that!! I use a G540 in a metal box with ferrites on all wires entering the control box. The frame of the mill is independently earth outside my workshop. I have switched off the limit switches in the Mach3 plasma profile I set up as the EMI was tripping them when I was doing test air cuts, but the pilot arc was continually firing so EMI would have been very high.

I took the wooden surface off my table, but put it back on again as I needed to mill a job. I've decided to just leave it on there and sit the water tray on top as it pretty much covers it so shouldnt get wet.

Last edited by spidey4fun on Wed Aug 26, 2020 8:44 am, edited 2 times in total.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11433

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Mill Conversion to Plasma cutter.

Nice work Brad!! I particularly like your torch mount. Did you print that yourself, or is it an off-the-shelf item? What machine torch are you using? There was a post recently where the OP ended up selling his Lotos LPT5000D because of the HF start, and I think he bought another brand with blowback start. You seem to have yours working well with the HF start. Other than turning off the limit switches and adding the ferrites and shielded box for the controller, have you taken any other precautions, and have you had any other noise/EMI related problems?

Thanks,

David

Thanks,

David

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

I designed the torch mount.

I also added an earth rod to ground the frame of the mill.

No issues yet, but I've only cut what you've seen. I've also taken out the springs from the touch off probe. They werent needed and in fact caused issues when probing very light metal.

I also added an earth rod to ground the frame of the mill.

No issues yet, but I've only cut what you've seen. I've also taken out the springs from the touch off probe. They werent needed and in fact caused issues when probing very light metal.

Last edited by spidey4fun on Wed Aug 26, 2020 8:47 am, edited 1 time in total.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11433

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Mill Conversion to Plasma cutter.

Nice! What machine torch did you buy to connect to your Lotos?

David

David

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11433

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

Great thing about DIY is you can build what you want to fit your style, plus hanging whatever options you want. Ending up with a multi-purpose table to be used on more projects, have fun

Tom

Tom

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

DieselFumes

- 3.5 Star Member

- Posts: 656

- Joined: Thu Dec 05, 2019 11:33 am

Re: Mill Conversion to Plasma cutter.

Nice man! Big undertaking, very impressive

Tracker CNC 4x4

Hypertherm 85

Hypertherm 85

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

Added a Proma 150 THC to my set-up as I need to cut some longer parts. Here's how I fitted it. Now I just have to figure out how to use it and get the setting right.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

Very nice video lots of info for the DIY types, Your table lift is slick too. A little added info for you with your rotary attachment you can use it for plasma cutting tubes or cylinders.

Simple create a profile for rotary and move the X axis cable to the rotary motor with the distance and speed changes in Mach motor control.

Simple create a profile for rotary and move the X axis cable to the rotary motor with the distance and speed changes in Mach motor control.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

Thanks. I plan on fitting the rotary for pipe cutting also.

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

I've been testing the Proma 150 trying to figure out the best cutting speeds / cuttings AMP's / Mach3 Anti-dive setting / Z-Axis Speed / Proma Voltage, D-T , Hysteresis... so much to figure out. Cutting 4mm steel. It all seems to work though!!

I also updated my control box. I purchased another G540 to control the rotary axis and provide more inputs. I removed the 2 of 4 limit switches I had and set up soft limits. The soft limit switches are only active during the ref all home function. After this you can manually trip them and it has no effect on the mills movement. Perfect solution when EMI trips the limit switches.

Time to start working on the rotary pipe cutter next.

I also updated my control box. I purchased another G540 to control the rotary axis and provide more inputs. I removed the 2 of 4 limit switches I had and set up soft limits. The soft limit switches are only active during the ref all home function. After this you can manually trip them and it has no effect on the mills movement. Perfect solution when EMI trips the limit switches.

Time to start working on the rotary pipe cutter next.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

Your getting closer just remember to create a cutting chart with the different voltages for metal thickness.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

What software is good for rotary pipe cutting? Ive been trying to create a test cutting path on the 4th axis and it jitters /jerks at any attempt at anything other then very slow stepping speed. Absolutely no fliud rotation from the created G-code. Yet it jogs fine.. weird!! When milling I only had it stepping slowly for rotation.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

There are many ways to do it, SheetCam has a software add on to do it. If your in business you can buy a rotary setup to attach to your table. If you a DIY and only want to do it a small amount it different. Here is a video of a guy doing laser etching with a rotary jig which is very smart and simple when you thing about it. He uses a strap and a flat pulley the same size of the part to keep the laser in sync with the object he etches.

I do it differently I have a jig that I mount on my table and I move the control cable from either the X or Y motor and connect it to the motor on my Jig. I recalibrate that axis for the diameter of the pipe/tube and just use a normal G-code to cut, very effective and simple. That is how the video was done. The axis drive is how you orientate the rotational jig. If you only do one or two diameter pipe you only need to calibrate for those and keep the numbers for changing when needed.

I do it differently I have a jig that I mount on my table and I move the control cable from either the X or Y motor and connect it to the motor on my Jig. I recalibrate that axis for the diameter of the pipe/tube and just use a normal G-code to cut, very effective and simple. That is how the video was done. The axis drive is how you orientate the rotational jig. If you only do one or two diameter pipe you only need to calibrate for those and keep the numbers for changing when needed.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

That sounds like a plan. I might try set that up. Im only looking to cut 4 different size pipes. I've used the unroll function previously to create paper templates. I'll try this for creating a cutting path. It seems Fusion360 4th axis software doesnt work with plamsa cutting either. At least that's what Im reading.

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

Well that seemed to work. I just un-rolled the pipe and created a tool path for it when flat using the regular manufacture plasma cutting. I set up a new profile in Mach3 with the rotary A -axis and the X - axis swapped. This allows me to jog the X axis over the pipe still. The G540 controller is 2000 steps per revolution. I have a 100:1 harmonic drive in the mix also. 2000 x 100 / 359.084 ( which is the circumference of the 114.3 diameter pipe) gives 556.9727 steps. I'll just set up a profile for each of the 4 pipes I need to cut. Here's the test.

-

plasmanewbie

- 5 Star Elite Contributing Member

- Posts: 2923

- Joined: Thu Jul 24, 2008 11:15 am

Re: Mill Conversion to Plasma cutter.

Super cool! Well done

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

DId a little more work today. As Im only planning on cutting 4 different size pipes I'll make supports for each diameter.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8526

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Mill Conversion to Plasma cutter.

Nice your getting closer, one thing to remember is the work lead path should not go through the chuck or bearings. the current flow may destroy the chuck scroll section. This may only cause a problem if you go into heavy cutting production type work. I used a simple plate with adjustable arms for the chuck and a braided mesh wrapped around the shaft for the current path.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 11433

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Mill Conversion to Plasma cutter.

On my rotary - I attach the work clamp directly to the pipe or tube being cut.

David

David

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

spidey4fun

- 1 Star Member

- Posts: 23

- Joined: Thu Jun 25, 2020 8:14 pm

Re: Mill Conversion to Plasma cutter.

Thanks for the feedback. I hadnt given much thought where to best place the earth lead. I can see how connecting it to anything other then the pipe might cause arcing issues.