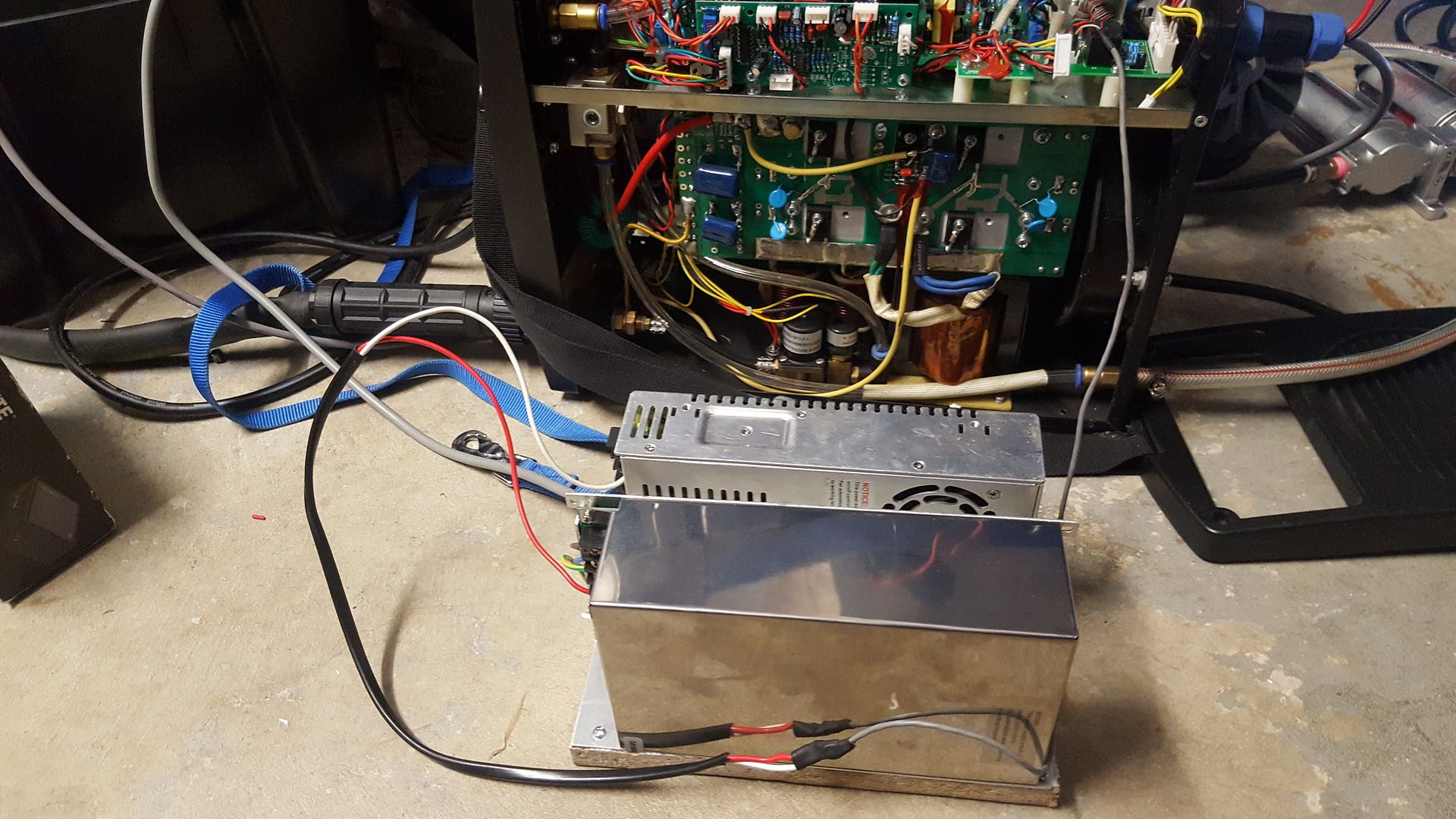

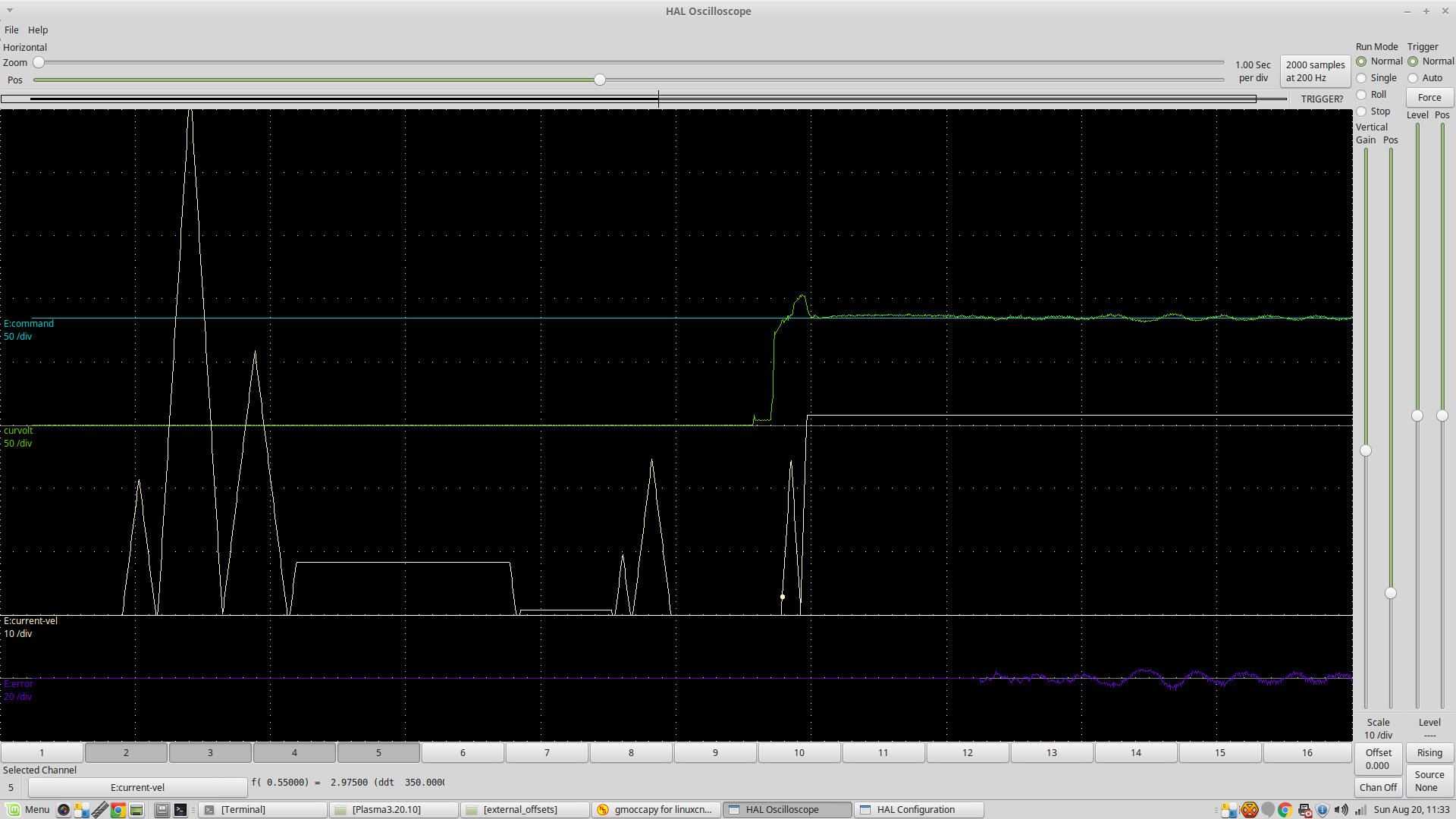

Steve thanks,the Mesa THCAD card used to measure the voltage contains surge protection and is specifically designed for plasma torch voltage reading. See http://store.mesanet.com/index.php?rout ... uct_id=127 Torch voltage is converted to a frequency that is sent to the Mesa 7i76e encoder input where it can be read by LinuxCNC in real time (1000 times a second). For testing, I have been logging the data with a FIFO buffer byte like this:sphurley wrote:The divider needs some noise filtering in it or you will get false voltage readings. It should also include some surge protection for your low voltage equipment.

Code: Select all

X coord Y coord Z coord Volts THCAD freq

263.000000 380.000000 -55.234143 81.969943 10266.940452

263.000000 380.000000 -55.237488 84.435688 10460.251046

263.000000 380.000000 -55.240757 83.754051 10406.811731

263.000000 380.000000 -55.243952 82.781669 10330.578512

263.000000 380.000000 -55.247072 83.741494 10405.827263

263.000000 380.000000 -55.250117 83.004798 10348.071496

263.000000 380.000000 -55.253087 82.104535 10277.492292

263.000000 380.000000 -55.255982 81.969943 10266.940452

263.000000 380.000000 -55.258802 82.509978 10309.278351

263.000000 380.000000 -55.261547 82.917936 10341.261634

263.000000 380.000000 -55.264217 81.567819 10235.414534

263.000000 380.000000 -55.266812 81.835627 10256.410256

263.000000 380.000000 -55.269332 82.756924 10328.638498

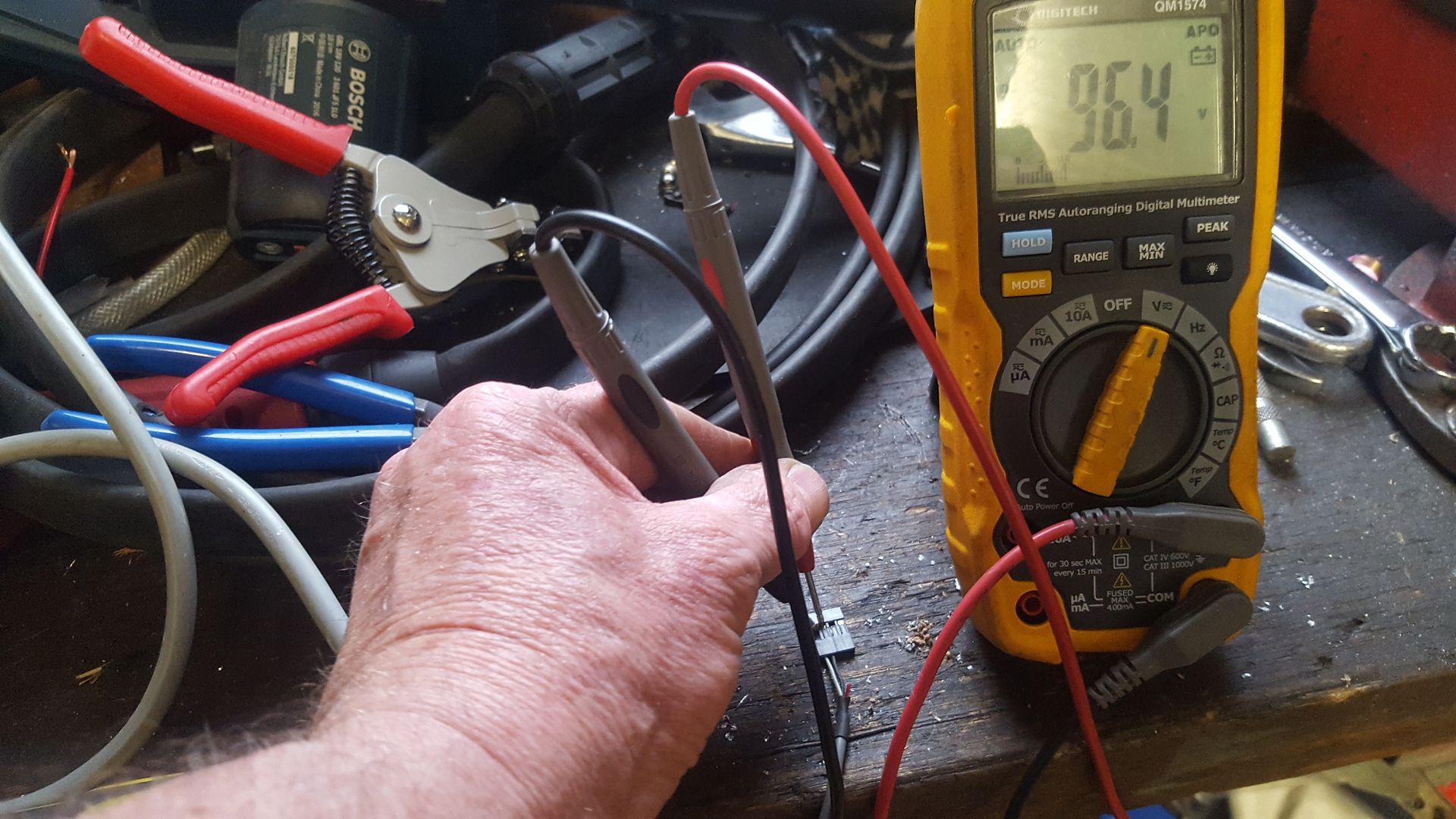

Its a shame I can't log the multimeter output, but from observation, it reads higher than the software during a run once the torch gets to a constant cutting height. The THC is not enabled but you can see that the Z axis is moving in this excerpt.

Filtering will be done in software using LinuxCNC's lowpass filter. See http://linuxcnc.org/docs/html/man/man9/lowpass.9.html

I've written a custom component to do the calculations that convert the recorded frequency back to voltage. I've embedded the lowpass filter code into this component but its disabled at the moment. One thing at a time!

I will be doing some more tests today. I've been lent a high quality Agilent multimeter as mine seems to be very slow reading values and updating the display.

The reality is that it does not matter what reading LinuxCNC receives as it will be used as an input to a PID control loop. Voltage conversion is just a convenience for the operator to display on screen. I may just use the raw frequency as the PID input.