scribe troubles

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

scribe troubles

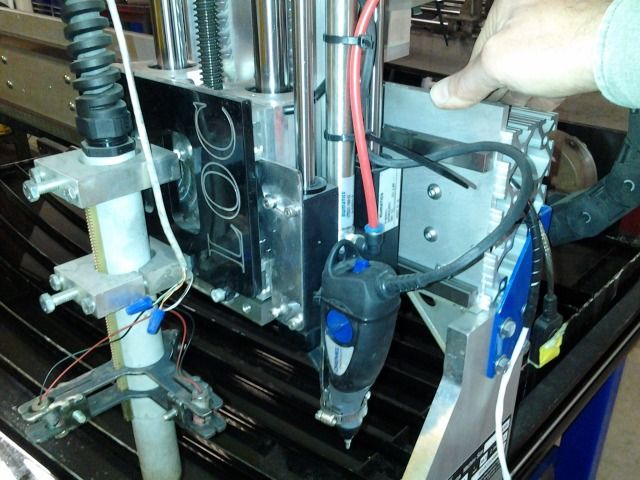

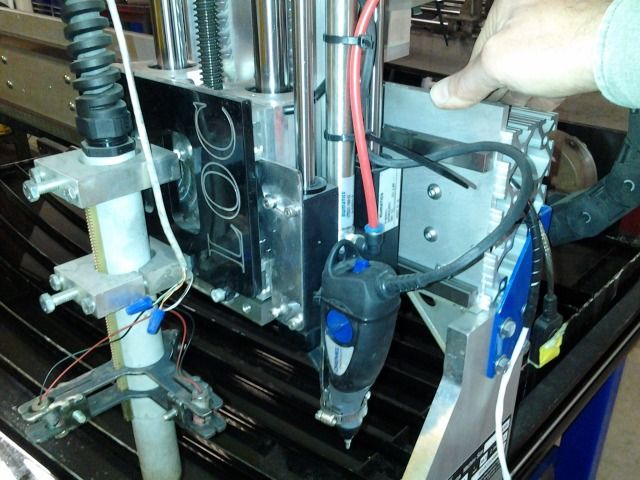

I just set up a scribe on my machine. A bulltear 4x8. I bought an SMC 16x100mm air slide, Sioux 5980 engraver, and 3way solenoid, regulator/filter and oiler for scribe circuit. For the slide circut I have a 5way solenoid, regulator/filter, and a 4-57psi regulator mounted next to the slide to control down movement air pressure.

it all seems to work perfectly, except im having trouble with down pressure setting, if I run more than about 3 or 4 psi the scribe will stall out. By running that low of down force psi, the slide goes down rather slowly, I have a 2 sec delay set, to give it time to extend. Its a bit inconsistent in its extending times also, I think because of the low pressure.

the Sioux engraver has a very sharp tip on it and it seems to bury itself into the metal quickly then when the gantry moves, it kinda has to yank it out of the hole sideways and it makes a skip.

im wondering if my issues are with the engraver. Is the cp9361 better suited? If you put too much downforce on them do they stall out? Ill post some pics of the setup

it all seems to work perfectly, except im having trouble with down pressure setting, if I run more than about 3 or 4 psi the scribe will stall out. By running that low of down force psi, the slide goes down rather slowly, I have a 2 sec delay set, to give it time to extend. Its a bit inconsistent in its extending times also, I think because of the low pressure.

the Sioux engraver has a very sharp tip on it and it seems to bury itself into the metal quickly then when the gantry moves, it kinda has to yank it out of the hole sideways and it makes a skip.

im wondering if my issues are with the engraver. Is the cp9361 better suited? If you put too much downforce on them do they stall out? Ill post some pics of the setup

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

Re: scribe troubles

I'll continue in a new post... I still have to organize my solenoid regulator setup obviously.

Im running just below 100 psi to the scribe, and 70psi to the slide(retract)and between 2-4psi extend. (Its hard to tell on the gauge, its basically on 0psi)

I've got my offset dialed in now.

Here is my first two tests. Ya I started out a bit elaborate for my first tests.

Im running just below 100 psi to the scribe, and 70psi to the slide(retract)and between 2-4psi extend. (Its hard to tell on the gauge, its basically on 0psi)

I've got my offset dialed in now.

Here is my first two tests. Ya I started out a bit elaborate for my first tests.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

-

blackandtan

- 2.5 Star Elite Contributing Member

- Posts: 212

- Joined: Thu Jul 18, 2013 3:05 pm

Re: scribe troubles

I have the CP9361 and it works good most of the time. For some reason on the first mark it will not always start scribing unless I manually turn it on over a scrap piece for a second. I guess it just needs to be warmed up  . I think I am running about 8-10 pounds of down pressure and does not seem to cause any problems. I would guess that the lack of down pressure is what is making it move down too slow. I know when I turned my pressure down to do aluminum it moved slow and inconsistent so I had to put a long delay on it, but then it had dimples on the spots that it decided to move normal. I would like to see the JD label when finished.

. I think I am running about 8-10 pounds of down pressure and does not seem to cause any problems. I would guess that the lack of down pressure is what is making it move down too slow. I know when I turned my pressure down to do aluminum it moved slow and inconsistent so I had to put a long delay on it, but then it had dimples on the spots that it decided to move normal. I would like to see the JD label when finished.

- tnbndr

- 4.5 Star Elite Contributing Member

- Posts: 1730

- Joined: Mon Jan 09, 2012 4:30 pm

- Location: New Berlin, WI

- Contact:

Re: scribe troubles

Not sure it helps but mine is set at about 20 for down pressure and 90 for scribe. It hammers down to the metal very quickly and does not drag when scribing. Mine seems to have a rounder point though it is not sharp, could be from a good amount of scribing.

I believe it is the CP9361 scribe, it came with my LDR table.

I believe it is the CP9361 scribe, it came with my LDR table.

Dennis

ComMarker B6 Galvo MOPA Fiber Laser

Hypertherm PM30 Hand Torch

RolAir 3HP Single Stage 30 Gal

13.8scfm@100psi, 3450RPM

Miller 215 MultiMatic

RW 390E Slip Roll (Powered)

AutoCAD, SheetCAM, Mach 3, Lightburn

ComMarker B6 Galvo MOPA Fiber Laser

Hypertherm PM30 Hand Torch

RolAir 3HP Single Stage 30 Gal

13.8scfm@100psi, 3450RPM

Miller 215 MultiMatic

RW 390E Slip Roll (Powered)

AutoCAD, SheetCAM, Mach 3, Lightburn

-

dhelfter

- 2.5 Star Member

- Posts: 125

- Joined: Wed Sep 09, 2009 11:18 pm

Re: scribe troubles

Dennis,

Yes yours is a cp9361. The tip we get with the scribe is rounded. We had trouble with the tips that were extremely pointed.

f_armer,

15-20 psi down pressure seems to work well, but all depends on what diameter cylinder you are using. 20psi on a 3/4" bore will develop 9lbs of force, but 20psi on a 1" bore will develop 16lbs force. Down force is what is important, you just use psi to get it! We have found 7-10 lbs of down force works well for most applications. Again your ideal pressure will depend on bore size of cylinder.

We use to mount the valves on the side of machine, and found the slide would go down slowly, and inconsistent. The entire air line has to be filled with air before any motion. We mount the valves right next to the cylinder now so less than 12" of line needs to be pressurized when we turn valve on.

Thanks

Dan

LDR

Yes yours is a cp9361. The tip we get with the scribe is rounded. We had trouble with the tips that were extremely pointed.

f_armer,

15-20 psi down pressure seems to work well, but all depends on what diameter cylinder you are using. 20psi on a 3/4" bore will develop 9lbs of force, but 20psi on a 1" bore will develop 16lbs force. Down force is what is important, you just use psi to get it! We have found 7-10 lbs of down force works well for most applications. Again your ideal pressure will depend on bore size of cylinder.

We use to mount the valves on the side of machine, and found the slide would go down slowly, and inconsistent. The entire air line has to be filled with air before any motion. We mount the valves right next to the cylinder now so less than 12" of line needs to be pressurized when we turn valve on.

Thanks

Dan

LDR

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

Re: scribe troubles

My slide is a 16mm x 100mm I'm thinking 16mm is the bore of the air cylinder so that would be about .62"dhelfter wrote:Dennis,

Yes yours is a cp9361. The tip we get with the scribe is rounded. We had trouble with the tips that were extremely pointed.

f_armer,

15-20 psi down pressure seems to work well, but all depends on what diameter cylinder you are using. 20psi on a 3/4" bore will develop 9lbs of force, but 20psi on a 1" bore will develop 16lbs force. Down force is what is important, you just use psi to get it! We have found 7-10 lbs of down force works well for most applications. Again your ideal pressure will depend on bore size of cylinder.

We use to mount the valves on the side of machine, and found the slide would go down slowly, and inconsistent. The entire air line has to be filled with air before any motion. We mount the valves right next to the cylinder now so less than 12" of line needs to be pressurized when we turn valve on.

Thanks

Dan

LDR

I mounted my down pressure regulator close to the slide thinking that would take care of any delay. But now that you mention it, having the solenoid closer would react more consistently, right?

I kinda think my scribe tip being so pointed is my main problem, it's like a needle. I can see a blunter tip being better.

Thanks for your suggestions.

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: scribe troubles

I have a different setup the down cylinder is separate from the slide and the solenoid is about 4' from the cylinder. And it reacts very fast it has an internal spring return so I don't need return air to make it go up. Running about 5 PSI for the cylinder and 90 on the scribe.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

dhelfter

- 2.5 Star Member

- Posts: 125

- Joined: Wed Sep 09, 2009 11:18 pm

Re: scribe troubles

acourtjester,

That is similar to our setup. We also have a separate cylinder and slide. And also use a single acting spring return cylinder. Sometimes the simplest setups are the most consistent.

f_armer

The regulator can be mounted on the machine base. The valve being closer to the cylinder is what will make motion happen faster. This setup also allows you to adjust air pressure, while scribing (during tests) without "chasing" the gantry.

Thanks

Dan

LDR

That is similar to our setup. We also have a separate cylinder and slide. And also use a single acting spring return cylinder. Sometimes the simplest setups are the most consistent.

f_armer

The regulator can be mounted on the machine base. The valve being closer to the cylinder is what will make motion happen faster. This setup also allows you to adjust air pressure, while scribing (during tests) without "chasing" the gantry.

Thanks

Dan

LDR

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: scribe troubles

i only run the one 5 port 2 way valve, similar to yours

but i run full pressure into the valve

i have flow control valves on both up and down to control up/down speed

after the down flow control valve i have the pressure regulator, i run approx 5psi down pressure

first: remove the exhaust silencers and run, sometimes they come plugged up

2nd: move the pressure regulator to the other side of the solenoid valve, the ports in those valves are very small and your running 3-4 psi thru the small port, choking the flow of 3-4 psi. if you do this without a flow control valve in the return/up line it will hammer up, so have the line pinched to keep it from hammering up.

3rd: if suggestion #2 works install flow control valves in both up/down lines

with air you control the flow coming out of the control valve into the cylinder (reverse of hydraulics)

i deal with a guy called mettle air on ebay; good prices, selection and delivery

the valves come in a variety of sizes

this is my setup with same basic valve, flow control and pressure regulator after both going into the air slide

i do have a .5 second delay in the tool setup

and a youtube video showing my air slide speed with 5 psi down pressure

this video show the electric scribe https://www.youtube.com/watch?v=5O8rjZ_3c_4

but i run full pressure into the valve

i have flow control valves on both up and down to control up/down speed

after the down flow control valve i have the pressure regulator, i run approx 5psi down pressure

first: remove the exhaust silencers and run, sometimes they come plugged up

2nd: move the pressure regulator to the other side of the solenoid valve, the ports in those valves are very small and your running 3-4 psi thru the small port, choking the flow of 3-4 psi. if you do this without a flow control valve in the return/up line it will hammer up, so have the line pinched to keep it from hammering up.

3rd: if suggestion #2 works install flow control valves in both up/down lines

with air you control the flow coming out of the control valve into the cylinder (reverse of hydraulics)

i deal with a guy called mettle air on ebay; good prices, selection and delivery

the valves come in a variety of sizes

this is my setup with same basic valve, flow control and pressure regulator after both going into the air slide

i do have a .5 second delay in the tool setup

and a youtube video showing my air slide speed with 5 psi down pressure

this video show the electric scribe https://www.youtube.com/watch?v=5O8rjZ_3c_4

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

Re: scribe troubles

I tried removing the silencers, it made no difference._Ogre wrote:i only run the one 5 port 2 way valve, similar to yours

but i run full pressure into the valve

i have flow control valves on both up and down to control up/down speed

after the down flow control valve i have the pressure regulator, i run approx 5psi down pressure

first: remove the exhaust silencers and run, sometimes they come plugged up

2nd: move the pressure regulator to the other side of the solenoid valve, the ports in those valves are very small and your running 3-4 psi thru the small port, choking the flow of 3-4 psi. if you do this without a flow control valve in the return/up line it will hammer up, so have the line pinched to keep it from hammering up.

3rd: if suggestion #2 works install flow control valves in both up/down lines

with air you control the flow coming out of the control valve into the cylinder (reverse of hydraulics)

i deal with a guy called mettle air on ebay; good prices, selection and delivery

the valves come in a variety of sizes

I moved the solenoid valve to the gantry, to see if was affecting it, it seemed better, but still not fast without turning the pressure up.

I have not tried moving the regulator to the other side of the solenoid, I have a regulator on the front side of the valve already, I wonder if I should just remove the regulator on the "down" side of the solenoid. I also already have flow control valves on the slide itself. Do you think that will work?

I going to attatch a schematic of how it is plumbed now.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

Re: scribe troubles

So I removed the low pressure regulator next to the slide, and tried adjusting the flow controls on the slide, it does seem to be more consistent, and I can make it move quicker. So I moved the solenoid back down under the table also, and it seems about the same. My 'up' movement isnt quite as quick, but thats probably okay. In the mean time I accidently touched the 110v output wires together(Iforgot to unplug the cord from the bladerunner box as I was unhooking the solenoid  )

)

So I cant test it as of right now because it shorted something out and I have no movement

So I cant test it as of right now because it shorted something out and I have no movement

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

-

f_armer

- 1.5 Star Member

- Posts: 49

- Joined: Sat Feb 22, 2014 1:42 am

- Location: Sask. Canada

Re: scribe troubles

Thought I'd update, when I shorted the wires from the control box, it never hurt anything in the box, but it took out the parallel port in my computer, so, easy fix. I just swapped out the computer for another.

After doing a bunch of experimenting with the flow control valves and moving regulators, and solenoids from down beside the table to the gantry, and back, I've come to the conclusion the scribe isn't suited very well for cnc work.

If I have just a few pounds of downforce the scribe will stall out (I can easily raise it with my finger while its scribing), and it seems to dig and get hooked in the metal at times. If I back the air pressure off anymore it takes forever to lower it down, then it just kinda floats on top the metal.

It works, but isn't reliable.

I'm going to order a CP9361 and see if that eliminates my troubles.

Is there a special round nose tip, or is the tip that comes with the 9361 already the one to use?

After doing a bunch of experimenting with the flow control valves and moving regulators, and solenoids from down beside the table to the gantry, and back, I've come to the conclusion the scribe isn't suited very well for cnc work.

If I have just a few pounds of downforce the scribe will stall out (I can easily raise it with my finger while its scribing), and it seems to dig and get hooked in the metal at times. If I back the air pressure off anymore it takes forever to lower it down, then it just kinda floats on top the metal.

It works, but isn't reliable.

I'm going to order a CP9361 and see if that eliminates my troubles.

Is there a special round nose tip, or is the tip that comes with the 9361 already the one to use?

4x8 bulltear

Hypertherm pm45

Miller 252

Miller syncrowave 210

Hypertherm pm45

Miller 252

Miller syncrowave 210

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: scribe troubles

you can buy electric scribes at home depot all day for $17,

knowing that i'd be hard pressed to spend $350 on an air scribe

i had a cheap air scribe for a bit; sometimes it'd start, sometimes not

i went back to the electric scribe

knowing that i'd be hard pressed to spend $350 on an air scribe

i had a cheap air scribe for a bit; sometimes it'd start, sometimes not

i went back to the electric scribe

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

-

RGR

- 2.5 Star Member

- Posts: 107

- Joined: Wed Dec 11, 2013 3:21 am

Re: scribe troubles

Ogre. Do you have any pictures of the results the electric scribe can produce. I've never seen on used before. I'm curios.

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: scribe troubles

if you watch this video... turn down the volume

https://www.youtube.com/watch?v=5O8rjZ_3c_4

i was scribing an angle finder for tube, pay no attention to the plasma cuts

i don't do any artsy work, mostly scribed bend lines

https://www.youtube.com/watch?v=5O8rjZ_3c_4

i was scribing an angle finder for tube, pay no attention to the plasma cuts

i don't do any artsy work, mostly scribed bend lines

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley