School me in how to add a plate marker ?

- Sampson Jones

- 3 Star Elite Contributing Member

- Posts: 336

- Joined: Mon Jul 25, 2011 9:30 pm

School me in how to add a plate marker ?

I want to add a plate marker to my home built 4 x 8 table . I have c and cnc electronics , Corel draw , and sheet cam ,and Mach 3 .I would like to engrave and then plasma cut , which I think would be the ultimate .

Here's the questions

1 . Do I do a regular dxf drawing in Corel draw ?

2. What do I need to do to set up sheet cam to do engraving ? How do I set up the operation also ? What processor do I use ?What would be the switch offset , please note I use the feather touch from c and cnc and it uses no switch off set .

3 . What do I do in Mach three ? What kind of settings and tips do I need to know about Mach before I push the button .

4 How do I set up a job to engrave and plasma cut ?

5 The parts and pieces look pretty simple , but I would be interested in any links to the parts , pieces , or assembly's?

Thanks so much !

Here's the questions

1 . Do I do a regular dxf drawing in Corel draw ?

2. What do I need to do to set up sheet cam to do engraving ? How do I set up the operation also ? What processor do I use ?What would be the switch offset , please note I use the feather touch from c and cnc and it uses no switch off set .

3 . What do I do in Mach three ? What kind of settings and tips do I need to know about Mach before I push the button .

4 How do I set up a job to engrave and plasma cut ?

5 The parts and pieces look pretty simple , but I would be interested in any links to the parts , pieces , or assembly's?

Thanks so much !

My design , 4ft x 8 ft water table

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: School me in how to add a plate marker ?

What I will tell you is from how I do it and others may do it differently. I don?t have my scribe/engraving tool mounted at the same time as the plasma torch and that is because I have a floating head on my torch. I can be done I just did not do it yet. I don?t think the feather touch options will interfere as it used an electrical contact not a mechanical movement contact.

Software there is really no difference for the drawing part and little for SheetCam or Mach 3. With SheetCam for plasma you move up from the surface and follow the cutting routine. For engraving or plate marking you start at Z zero and go down and follow the routine. If you do routing or milling SheetCam has a pocket option for removing material around what you want to keep/design. You can remove inside lettering or all around lettering. This is done with contouring or pocketing tool operations.

You have optional relay circuits in the CandCNC electronics to trigger the engraver or plate marker. With engraving you could just manually turn on the engraver/router when you start and off when finished.

You may use many different post processors they just need to have any reference to the feather touch routine removed. SheetCam will tell mach if it needs to go positive or negative with the tool movement.

Search here for plate marker posts and you will find great other info too.

Software there is really no difference for the drawing part and little for SheetCam or Mach 3. With SheetCam for plasma you move up from the surface and follow the cutting routine. For engraving or plate marking you start at Z zero and go down and follow the routine. If you do routing or milling SheetCam has a pocket option for removing material around what you want to keep/design. You can remove inside lettering or all around lettering. This is done with contouring or pocketing tool operations.

You have optional relay circuits in the CandCNC electronics to trigger the engraver or plate marker. With engraving you could just manually turn on the engraver/router when you start and off when finished.

You may use many different post processors they just need to have any reference to the feather touch routine removed. SheetCam will tell mach if it needs to go positive or negative with the tool movement.

Search here for plate marker posts and you will find great other info too.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

kkroger

- 2.5 Star Member

- Posts: 225

- Joined: Sat Apr 26, 2014 7:56 pm

Re: School me in how to add a plate marker ?

Acourtjester has plans for such.

I am currently building my own and I will post a tutorial soon.

Ron at Precision Plasma LLC sells a kit that runs about $750 without the scribe.

I am building one that should come in UNDER $300 with scribe.

You need an Air linear Thruster, a way to mount it to your Z axis so that the torch can touch off then lift to the desired height and then deploy the thruster. The one I will be using is about $475 Retail, I found a NOS out of box unused one for $40

it is a 25mm bore, 100mm travel...

You will need two air solenoids (E-bay for about $50 for both)(110VAC a 3 way and a 4 way)

you will need 3 regulators, and two Filters and an oiler for the scribe...

I am useing the scribe that Tom (Acourtjester) uses... I found it for $49 on Amazon, shipped...

Then past that multiple fitting and air line... McMaster sells this stuff.

CandCNC should have two aux outlets on the controller, one for each solenoid They should also have a post processor available on their website that works with a scribe... Sheetcam should be able to use it. You just have to build the tool correctly in the software.

Like I say I am currently accumulating the parts, I should have most of it this week then next saturday picking up the material for the brackets.

I'll do photos and videos as needed.

I am currently building my own and I will post a tutorial soon.

Ron at Precision Plasma LLC sells a kit that runs about $750 without the scribe.

I am building one that should come in UNDER $300 with scribe.

You need an Air linear Thruster, a way to mount it to your Z axis so that the torch can touch off then lift to the desired height and then deploy the thruster. The one I will be using is about $475 Retail, I found a NOS out of box unused one for $40

it is a 25mm bore, 100mm travel...

You will need two air solenoids (E-bay for about $50 for both)(110VAC a 3 way and a 4 way)

you will need 3 regulators, and two Filters and an oiler for the scribe...

I am useing the scribe that Tom (Acourtjester) uses... I found it for $49 on Amazon, shipped...

Then past that multiple fitting and air line... McMaster sells this stuff.

CandCNC should have two aux outlets on the controller, one for each solenoid They should also have a post processor available on their website that works with a scribe... Sheetcam should be able to use it. You just have to build the tool correctly in the software.

Like I say I am currently accumulating the parts, I should have most of it this week then next saturday picking up the material for the brackets.

I'll do photos and videos as needed.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: School me in how to add a plate marker ?

Here are the SheetCam tools you will need, you create them from the rotary tool list.

While your at it why not also add the option of a Drag knife for vinyl cutting.

While your at it why not also add the option of a Drag knife for vinyl cutting.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

tcaudle

- 4 Star Elite Contributing Member

- Posts: 1635

- Joined: Tue Feb 28, 2012 6:47 pm

Re: School me in how to add a plate marker ?

All of the latest posts include "scriber" (plate marker) tool. It does several things

1. It allows you to define offsets in XY and Z in case you mount the plate marker on the same Z axis as the torch.

2. It automatically figures out the XY offset in the running code so you don't have to cahnge anything in your drawing

3 it swaps the Torch on output to one of the 129VAC aux sockets on the controller.

It does all of the above by you picking the "PlateMarker" tool in a plasma tool set. All you have to do to use it is to do ahead and do your 2D drawing an include the toolpath you want to mark or center punch. When you are processing the drawing in SheetCAM you setup a different layer for the marker process (or even several layers) and in the operation for that layer you select the Plate Marker tool. You can mix cuts within the job by just using the layers, operations and tool selection.

On other option added to recent POSTS is the "Plasma Peck" option. It lets you define a "drill" tool (so it automatically finds the center of a hole) It lets you define the height to peck fire the torch , the peck duration (typically .2 to .5 sec) and, if you have the TAP setup for your Hypertherm, the peck current as well. You go ahead and put holes in the drawing. I use 1/4" holes regardless of the actual hole size it will be drilled so I don't have to define but one drill tool The objective it to gouge the start of a hole that tends to be dish shaped, without fully penetrating the metal. It can get tricky on thinner material but it can be done, One thing it does, is on the first peck it lifts the torch and short fires the torch to start the purge air so the ON off will do the short cycle. If you don't do that the first peck will always blow through.

One thing we found on the plate markers: Wear hearing protection! on thinner material it will be so loud it will drive you out of the room and leave your ears ringing like a 70's rock concert!

1. It allows you to define offsets in XY and Z in case you mount the plate marker on the same Z axis as the torch.

2. It automatically figures out the XY offset in the running code so you don't have to cahnge anything in your drawing

3 it swaps the Torch on output to one of the 129VAC aux sockets on the controller.

It does all of the above by you picking the "PlateMarker" tool in a plasma tool set. All you have to do to use it is to do ahead and do your 2D drawing an include the toolpath you want to mark or center punch. When you are processing the drawing in SheetCAM you setup a different layer for the marker process (or even several layers) and in the operation for that layer you select the Plate Marker tool. You can mix cuts within the job by just using the layers, operations and tool selection.

On other option added to recent POSTS is the "Plasma Peck" option. It lets you define a "drill" tool (so it automatically finds the center of a hole) It lets you define the height to peck fire the torch , the peck duration (typically .2 to .5 sec) and, if you have the TAP setup for your Hypertherm, the peck current as well. You go ahead and put holes in the drawing. I use 1/4" holes regardless of the actual hole size it will be drilled so I don't have to define but one drill tool The objective it to gouge the start of a hole that tends to be dish shaped, without fully penetrating the metal. It can get tricky on thinner material but it can be done, One thing it does, is on the first peck it lifts the torch and short fires the torch to start the purge air so the ON off will do the short cycle. If you don't do that the first peck will always blow through.

One thing we found on the plate markers: Wear hearing protection! on thinner material it will be so loud it will drive you out of the room and leave your ears ringing like a 70's rock concert!

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: School me in how to add a plate marker ?

great info thanks filed away

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- Sampson Jones

- 3 Star Elite Contributing Member

- Posts: 336

- Joined: Mon Jul 25, 2011 9:30 pm

Re: School me in how to add a plate marker ?

Can the marker be mounted on the touch and go z axis where my torch is mounted ? I have a rack and pinion z . Why would you need an air cylinder ? Thanks everyone for your help so far .

My design , 4ft x 8 ft water table

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

-

kkroger

- 2.5 Star Member

- Posts: 225

- Joined: Sat Apr 26, 2014 7:56 pm

Re: School me in how to add a plate marker ?

if you don't have the air cylinder and the solenoids you will have to run the Z down to the table (tip of the scribe) with the electric motor, then it will have to retract and back down etc. Takes LONGER the slide will depoly in less than a second.

Watch This Video...

http://www.youtube.com/watch?v=92MiZrY44tI

Shows the Scribe operating, your R&P won't be accurate enough (my opinon) and the timing to get the scribe activated and your really don't want the scribe operating in air, it needs to contact the surface before operating.

the Scribe runs on air anyway so you already have that and deployment is FAST.

Watch This Video...

http://www.youtube.com/watch?v=92MiZrY44tI

Shows the Scribe operating, your R&P won't be accurate enough (my opinon) and the timing to get the scribe activated and your really don't want the scribe operating in air, it needs to contact the surface before operating.

the Scribe runs on air anyway so you already have that and deployment is FAST.

-

tcaudle

- 4 Star Elite Contributing Member

- Posts: 1635

- Joined: Tue Feb 28, 2012 6:47 pm

Re: School me in how to add a plate marker ?

Unless you want to stop and swap out the heads you cannot simple co-mount the scriber tot he Z with the torch. The scriber has to hand further than the torch does if you leave it on the Z. The down pressure of the scribe is controller by the down cylinder air pressure (same one that retracts and extends. Each device has its own regulator so the scriber air pressure is set and the down cylinder is set separately and can be adjusted to add in more or less force. It's real handy to have it so you simply pick a different tool in SheetCAM and it retracts the torch , extends the scriber and marks the plate without having to stop, change the heads out and rezero everything manually.

- captdick

- 2 Star Elite Contributing Member

- Posts: 63

- Joined: Mon Dec 21, 2009 11:13 am

- Location: Lodi, Wisconsin

Re: School me in how to add a plate marker ?

I understand how to do the Mechanics but still don't get the SPECIFCS as to how to set up in SHEETCAM. Can someone post a step by step tutorial .

Have a Precision plasma Gantry and Toms electronics. [candcnc]

Have a Precision plasma Gantry and Toms electronics. [candcnc]

- WyoGreen

- 4 Star Member

- Posts: 895

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: School me in how to add a plate marker ?

Here's some info that I've copied from various sites on the internet that I used to set my scribe up.

Steve

Steve

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- Sampson Jones

- 3 Star Elite Contributing Member

- Posts: 336

- Joined: Mon Jul 25, 2011 9:30 pm

Re: School me in how to add a plate marker ?

That's why this is the best site arround ! Thanks everyone and wyogreen you just saved me a ton of time and frustration !

My design , 4ft x 8 ft water table

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

CandCNC electronics

Hypertherm powermax 65

Command Lineux

Super z 2

Sheetcam

Inkscape and corel draw

- captdick

- 2 Star Elite Contributing Member

- Posts: 63

- Joined: Mon Dec 21, 2009 11:13 am

- Location: Lodi, Wisconsin

Re: School me in how to add a plate marker ?

Thanks -----Big Help

-

blackandtan

- 2.5 Star Elite Contributing Member

- Posts: 212

- Joined: Thu Jul 18, 2013 3:05 pm

Re: School me in how to add a plate marker ?

I see a few people are using the generic plate marker or scribe. How do you like it and do any of you know if the CP tips will fit them? There is a huge price difference in the generic and the CP.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: School me in how to add a plate marker ?

I have only use the cheap ones I bought 2 over time one form China and the other from India they look identical.

The one from Chine I could use the replacement tip from a CP vender the one from India would not work see attached for the difference. I tried to put a spacer in the scribe to use the CP tip but could not get it to work

And with both I have to break them down and polish the inside piston and piston housing to get them to work after that they will work. The manufactures do poor finish work and I do not think they test them either.

I do think the one from c

China is a direct copy and that is why the tip works it it. Ebay did not have the one from China lately ??

The one from Chine I could use the replacement tip from a CP vender the one from India would not work see attached for the difference. I tried to put a spacer in the scribe to use the CP tip but could not get it to work

And with both I have to break them down and polish the inside piston and piston housing to get them to work after that they will work. The manufactures do poor finish work and I do not think they test them either.

I do think the one from c

China is a direct copy and that is why the tip works it it. Ebay did not have the one from China lately ??

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

blackandtan

- 2.5 Star Elite Contributing Member

- Posts: 212

- Joined: Thu Jul 18, 2013 3:05 pm

Re: School me in how to add a plate marker ?

Thanks for the info on that, for 50 bucks I think I will try the cheap one. It would be nice if the CP tips would work though.

-

blackandtan

- 2.5 Star Elite Contributing Member

- Posts: 212

- Joined: Thu Jul 18, 2013 3:05 pm

Re: School me in how to add a plate marker ?

I bought the cheap scribe and it was the one from India and almost as soon as it touches the plate it quits regardless of the air pressure. Any suggestions? I took it apart and the piston moves freely in the bore so I don't know what else to try.

-

plain ol Bill

- 3.5 Star Elite Contributing Member

- Posts: 687

- Joined: Fri Aug 15, 2008 6:22 pm

- Location: Tenino,WA

Re: School me in how to add a plate marker ?

blackandtan - my advice - buy a CP.

plain ol Bill

Hypertherm 1250

Duramax machine torch

Corel Draw X6

Sheetcam

Mach3

5 x 10 self built table

Lots of ineptitude

Hypertherm 1250

Duramax machine torch

Corel Draw X6

Sheetcam

Mach3

5 x 10 self built table

Lots of ineptitude

-

blackandtan

- 2.5 Star Elite Contributing Member

- Posts: 212

- Joined: Thu Jul 18, 2013 3:05 pm

Re: School me in how to add a plate marker ?

I knew that was coming  , I was going to but ran out of funds after the build the hdiy gantry and the pmx 65. Hopefully I can get this to work until I get some money back out of all of this.

, I was going to but ran out of funds after the build the hdiy gantry and the pmx 65. Hopefully I can get this to work until I get some money back out of all of this.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8527

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: School me in how to add a plate marker ?

Having to monkey with the 2 I bought first do you have the 2 "O" rings of the tip like shown in the pictures. They act like spring returns the other thing is the piston must hit the tip end so it don't go to far down. These thing work like the old steam locomotives the air stream push down on piston and closes off air steam for down and opens other air stream for push back up. but if it goes to far it will not reutrn.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

tm america

- 2.5 Star Member

- Posts: 150

- Joined: Sat Feb 23, 2013 12:24 am

Re: School me in how to add a plate marker ?

I see a lot of guys mounting them to the z axis?Kind of curious why do that?Why not mount it to the x-z axis carrier and just let the air cylinder handle the up and down of the scribe?Also had a question to the diameter of the cylinders everyone is using I am thinking a 3/4inch diameter might work great at say 100psi and run the scribe and cylinder off the same soloniod?I would probably still do separate regulators ..The controllers I use on my machines have two unused relays when in the plasma configuration and I still have around 12 digital pins I could use to control the relay..I see you can do the post processing in sheetcam but I am working on a post processor in cambam instead....

-

muzza

- 4 Star Member

- Posts: 1445

- Joined: Wed Feb 04, 2009 5:35 pm

Re: School me in how to add a plate marker ?

My guess is convenience and to keep the the scribe point as close to torch point as practical to maximize working area on jobs requiring both plasma and scribe.tm america wrote:I see a lot of guys mounting them to the z axis?Kind of curious why do that?Why not mount it to the x-z axis carrier and just let the air cylinder handle the up and down of the scribe?Also had a question to the diameter of the cylinders everyone is using I am thinking a 3/4inch .

The cylinder I have to use is 20 mm bore X 100 mm stroke.

Murray

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: School me in how to add a plate marker ?

you need a non-rotational air slide, a standard air cylinder will rotate and the scribe will be all over the place

my z axis has 12 inches of clearance under it, that would take a loong cylinder to meet the work

as is i still have a 6 inch air slide attached to my z axis, this allows the scribe to clear fixtures on my table

if the clearance under your z axis isn't a lot you could easily attach the scribe to the z axis carrier

it would work the same as attached to the z axis slide

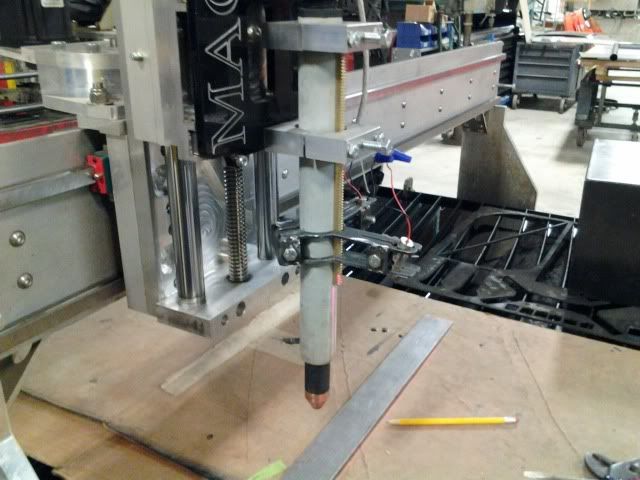

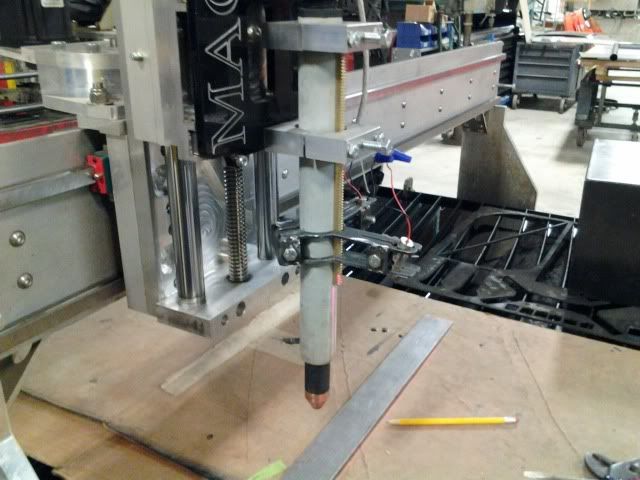

here is my mount and air slide. my torch hangs 8'' under the holder plus i have 6'' of z axis travel

as we have found out; there are many ways to hook up the scribe/slide

i use one valve and one regulator, my regulator only controls down pressure at approx 5 psi

i use flow control valves to set the up/down speed

my z axis has 12 inches of clearance under it, that would take a loong cylinder to meet the work

as is i still have a 6 inch air slide attached to my z axis, this allows the scribe to clear fixtures on my table

if the clearance under your z axis isn't a lot you could easily attach the scribe to the z axis carrier

it would work the same as attached to the z axis slide

here is my mount and air slide. my torch hangs 8'' under the holder plus i have 6'' of z axis travel

as we have found out; there are many ways to hook up the scribe/slide

i use one valve and one regulator, my regulator only controls down pressure at approx 5 psi

i use flow control valves to set the up/down speed

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

-

tm america

- 2.5 Star Member

- Posts: 150

- Joined: Sat Feb 23, 2013 12:24 am

Re: School me in how to add a plate marker ?

My x -z axis carriers are made to run two z axis so I would have a slide for the scribe and use the cylinder for the actuation ..My set up has 6.5 inches of clearance but I could hang the scribe a little lower so I could run a 6 inch travel cylinder..I am probably gonna do another design on the x-z axis carrier to allow me to have the torch,scribe and a dremel all mounted separately.that way there is no tools needed to switch from one to the other just write the g code accordinly

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: School me in how to add a plate marker ?

if you go that route with a separate scribe and dremel mount and you don't use the the other output on the bladerunner box

you can modify the scribe post processor to run the other output by changing all the m08 commands to m07 in the post

save one for scribe post and one for dremel post

fyi... dremel makes the electric scribe i use/bought from home depot. mine would be dremel and dremel

you can modify the scribe post processor to run the other output by changing all the m08 commands to m07 in the post

save one for scribe post and one for dremel post

fyi... dremel makes the electric scribe i use/bought from home depot. mine would be dremel and dremel

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley