Who are we/What do we do

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Who are we/What do we do

The Star Lab crew is comprised of a group of folks from different industrial backgrounds. We have on staff support personnel, several machinist, engineers and even a mathematician. Our goal with the Star Lab machines is to deliver the smoothest operating, longest lasting CNC platform on the planet. Designed mainly from an operators perspective not solely from a profit standpoint. This lead us to heavy use of hardened and ground and protected linear rails. The same rails you will find in the highest end of automation.

A quality part made from the initial plasma cut to the cut made far in the future will be the sum of all components. Not only how well they were designed and assembled but the quality of the those components. All of our engineering is done in house and the designs are not constrained by any outside influences. We use Metric and SAE components and hardware. Applications where there were no components available we designed and made in our machine shop.

Service life is one of the biggest factors in the mechanical and electrical portions of these machines. The ability to integrate linear rails that can withstand tens of millions of cycles versus a bearing on steel that may last tens of thousands and with more resistance (think router) was a critical design parameter for our machines. This is not easy to achieve and not a simple task.

To build in production a major investment in large capacity machining capability was made. We can in house machine 5 out of 6 basic sides of a CNC machine frame in one fixture without having to adjust or re-position. This gives us a huge advantage with much less fixturing time and that savings is passed onto the customer. The highest end of quality is something we strive for. There is not one piece or component of the Star Lab that was simply bolted on or fabb'ed up without rigorous analysis. We are proud to bring this industry into the next generation of machines and look forward to the advancements in cutting technology. We have multi axis milling, turning, grinding and large capacity cnc equipment so we minimize and eliminate as much outsourcing as possible. With our purchasing power and capabilities we can machine, grind, weld, paint, install and test cheaper than one could put one of our CNCs together from scratch. Let us know if your searching for a machine or want to learn more about the technology we offer.

A quality part made from the initial plasma cut to the cut made far in the future will be the sum of all components. Not only how well they were designed and assembled but the quality of the those components. All of our engineering is done in house and the designs are not constrained by any outside influences. We use Metric and SAE components and hardware. Applications where there were no components available we designed and made in our machine shop.

Service life is one of the biggest factors in the mechanical and electrical portions of these machines. The ability to integrate linear rails that can withstand tens of millions of cycles versus a bearing on steel that may last tens of thousands and with more resistance (think router) was a critical design parameter for our machines. This is not easy to achieve and not a simple task.

To build in production a major investment in large capacity machining capability was made. We can in house machine 5 out of 6 basic sides of a CNC machine frame in one fixture without having to adjust or re-position. This gives us a huge advantage with much less fixturing time and that savings is passed onto the customer. The highest end of quality is something we strive for. There is not one piece or component of the Star Lab that was simply bolted on or fabb'ed up without rigorous analysis. We are proud to bring this industry into the next generation of machines and look forward to the advancements in cutting technology. We have multi axis milling, turning, grinding and large capacity cnc equipment so we minimize and eliminate as much outsourcing as possible. With our purchasing power and capabilities we can machine, grind, weld, paint, install and test cheaper than one could put one of our CNCs together from scratch. Let us know if your searching for a machine or want to learn more about the technology we offer.

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

-

motoguy

- 4 Star Member

- Posts: 1184

- Joined: Tue Aug 25, 2015 12:05 pm

- Location: Central MO, USA

Re: Who are we/What do we do

In addition, the BTA Plasma crew are VERY personable, willing to answer a bazillion calls and e-mails prior to purchase, offer free pizza when you pick up a machine, are entertaining as hell, offer AMAZING post-sale customer support (sometimes...even if you don't own one of their machines!), and Matt will go out of his way to get you up and running when you have an issue. Even if his most appropriate response SHOULD have been, "Dumbass! Why on God's green earth would you do something as stupid as that?"

Oh...and you get to hear him say "aboot!"

PS: Did I mention the machines themselves are superb? I'm just now growing to appreciate the fact that my torch mount plate has a pair of pre-drilled, pre-tapped "ears" on either side, to accept "accessories". I have a pen holder mounted to one ear, and working on mounting an air scribe to the other. I've already got the Bulltear mount/plate for the Bosch router, though I haven't had a chance to play with it yet. Air scribe, pen mount, engraver, router, drag knife, laser...all easy to add to the machine later.

I'll concede I'm a bit of a nut-swinger when it comes to the BTA mahines / Matt's support. However, the fact is that he's saved me from my own stupidity on SEVERAL occasions. So, he's earned it, IMO.

Oh...and you get to hear him say "aboot!"

PS: Did I mention the machines themselves are superb? I'm just now growing to appreciate the fact that my torch mount plate has a pair of pre-drilled, pre-tapped "ears" on either side, to accept "accessories". I have a pen holder mounted to one ear, and working on mounting an air scribe to the other. I've already got the Bulltear mount/plate for the Bosch router, though I haven't had a chance to play with it yet. Air scribe, pen mount, engraver, router, drag knife, laser...all easy to add to the machine later.

I'll concede I'm a bit of a nut-swinger when it comes to the BTA mahines / Matt's support. However, the fact is that he's saved me from my own stupidity on SEVERAL occasions. So, he's earned it, IMO.

Bulltear 6x12 w/ Proton Z axis & watertable

CommandCNC/Linux w/ Ohmic & HyT options

Hypertherm Powermax 85 w/ machine torch

Solidworks, Coreldraw X7, Inkscape, Sheetcam

CommandCNC/Linux w/ Ohmic & HyT options

Hypertherm Powermax 85 w/ machine torch

Solidworks, Coreldraw X7, Inkscape, Sheetcam

-

jimcolt

- 5 Star Elite Contributing Member

- Posts: 3087

- Joined: Mon Jul 20, 2009 11:18 pm

- Location: North Carolina

Re: Who are we/What do we do

I hear nothing but good things from the many BullTear/Starlab owners that I have spoken with. Great machines and superb after sale support goes a long way when choosing the right cnc plasma! Jim Colt Hypertherm

-

Bigrhamr

- 2.5 Star Member

- Posts: 147

- Joined: Fri Jan 15, 2010 7:32 pm

Re: Who are we/What do we do

I've been looking at your website and your table would definitely be on my list of contenders for a new one.

Are there any more detailed pics posted any where? Would like to be able to see up close views of components like X and Y rails,

gantry end trucks, motor mounting, etc..

Are there any more detailed pics posted any where? Would like to be able to see up close views of components like X and Y rails,

gantry end trucks, motor mounting, etc..

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

We use T style rails that are 4 row linear rails for Y and Z axis. The T style designates bolt from the back. This keeps the debris and dust from collecting on the rail and destroying the linear truck. All the linear trucks we use for the T style are 6 wiper/scrapers per truck as you would find in a CNC mill or lathe application. It is the hardest rail to integrate from a MFGs perspective but the longest lasting linear rail style available. You typically see these types of linear rail bolt on from the front and a plastic button put on. The Y axis which is going to see the majority of the vaporized metal and water vapor is an area you don't want to cheap out on. The gear rack is attached from inside the gantry like the rails and is hand indicated so it does not have any appreciable backlash throughout the travel. This is important as we rigid mount the motors and do not rely on springs or air pressure to push the pinion gear into the gear rack (and wear out a gear much faster). The gear rack is 3/4" x 1" and all our machine travel over the advertised specifications. (ie....4x8 = 49.5x98 travel).

We use a Kevlar re-enforced timing belt and a very specific ratio to our reduction units on the stepper systems. There is a 1/2 hardened and ground gauge pin that is hard milled for the main drive shaft for the pinion gear. The pulleys are also married to the main drive and the motor. So much so that if you have a motor issue then we issue you a new motor with a precision timing pulley married to it. When we use servo we are using a minimum of a 10-1 ratio high precision gear box for X, Y and slave axis.

As we have time I will post up more specifications on these amazing machines. Oh and BTW there are 2 demo units coming in. Check our website www.Plasmaland.com

We use a Kevlar re-enforced timing belt and a very specific ratio to our reduction units on the stepper systems. There is a 1/2 hardened and ground gauge pin that is hard milled for the main drive shaft for the pinion gear. The pulleys are also married to the main drive and the motor. So much so that if you have a motor issue then we issue you a new motor with a precision timing pulley married to it. When we use servo we are using a minimum of a 10-1 ratio high precision gear box for X, Y and slave axis.

As we have time I will post up more specifications on these amazing machines. Oh and BTW there are 2 demo units coming in. Check our website www.Plasmaland.com

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

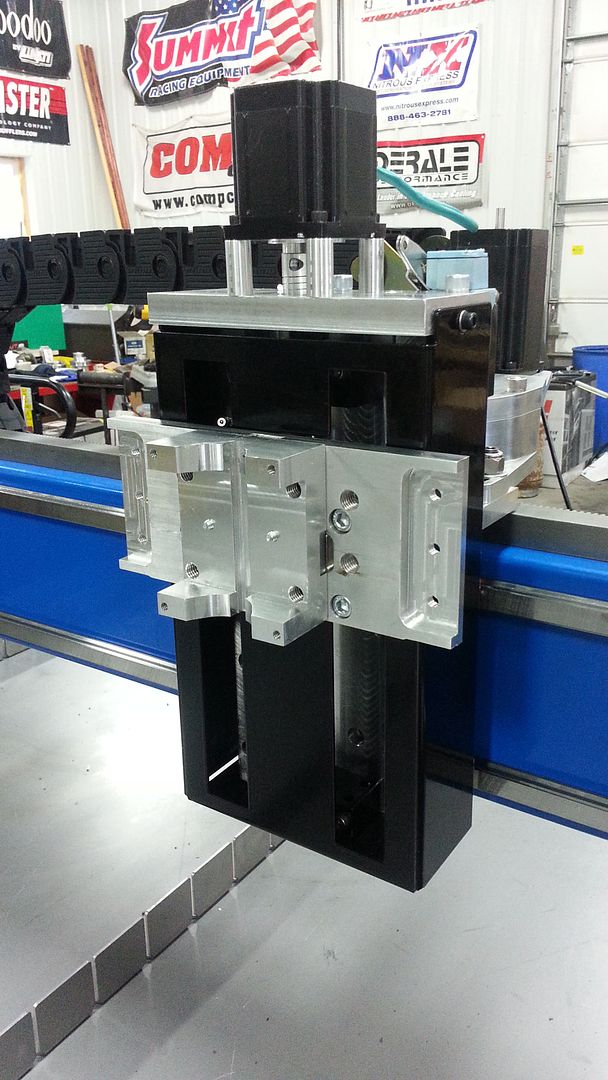

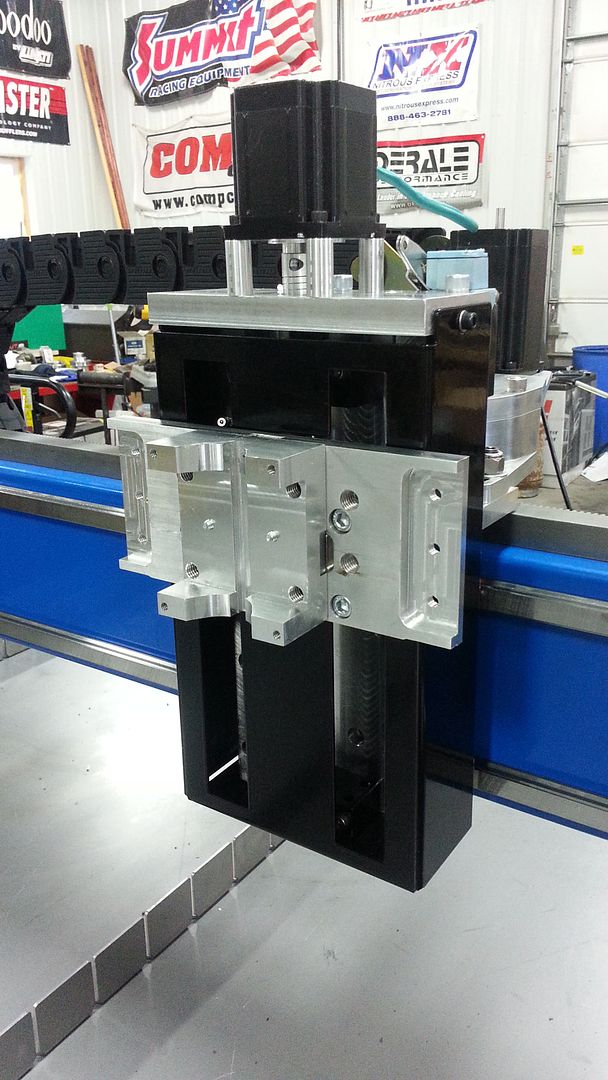

Every piece is machined on all sides. This gives us a precision assembly. Here is the style of rail we use but T designation and bolted from the back. There are literally hundreds of precision holes both in location and diameter for the assembly. That means there are hundreds and hundreds of bolts inside the gantry holding the rails and gear rack on the unit.

Our Z axis was also designed by us from the ground up. It has twin 25MM rails with 6 scrapers each and a double anchored, double scraper balls crew (this keeps the ball screw lubed and minimized vibration (double anchored)). It has a limit at the top and the bottom BUT it has a single switch at the top. This is very important as any switch near the cut zone will have a very poor service life. It is a rigid Z axis that also uses 6 rare earth magnets, nickel plated and countersunk for a firm grip on the torch but the ability to let it go if it hits something. The torch clamps are also a true radius clamp that uses a smooth radius in 6 areas rather than single contact angle. The magnetic clamp was minimized to shed any and all weight so it is heavily pocket milled as are all the machined components. The Z axis also has 2 extra precision pockets with tapped holes for anything you want to add for use with a I/O or the 2 120V AC relays that the electronics come with. It also has a robust 7/16-14 hole pattern for less than 1 minute change-over from plasma to router.

Our frames are 4x4 thick wall powder coated full steel weldments with 5/8" thick feet and each foot has a 3/4-16 tapped hole. They can take a hit! Here is a quick snapshot of the side unit and reduction unit. Our resellers (welding suppliers) often tell us we are the highest quality mfgs of a CNC plasma table and they have said its hard to believe they can be built with such consistancy. Well...thats what you get when your using CNC machines and measuring tools for each part.

Our Z axis was also designed by us from the ground up. It has twin 25MM rails with 6 scrapers each and a double anchored, double scraper balls crew (this keeps the ball screw lubed and minimized vibration (double anchored)). It has a limit at the top and the bottom BUT it has a single switch at the top. This is very important as any switch near the cut zone will have a very poor service life. It is a rigid Z axis that also uses 6 rare earth magnets, nickel plated and countersunk for a firm grip on the torch but the ability to let it go if it hits something. The torch clamps are also a true radius clamp that uses a smooth radius in 6 areas rather than single contact angle. The magnetic clamp was minimized to shed any and all weight so it is heavily pocket milled as are all the machined components. The Z axis also has 2 extra precision pockets with tapped holes for anything you want to add for use with a I/O or the 2 120V AC relays that the electronics come with. It also has a robust 7/16-14 hole pattern for less than 1 minute change-over from plasma to router.

Our frames are 4x4 thick wall powder coated full steel weldments with 5/8" thick feet and each foot has a 3/4-16 tapped hole. They can take a hit! Here is a quick snapshot of the side unit and reduction unit. Our resellers (welding suppliers) often tell us we are the highest quality mfgs of a CNC plasma table and they have said its hard to believe they can be built with such consistancy. Well...thats what you get when your using CNC machines and measuring tools for each part.

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

-

Bigrhamr

- 2.5 Star Member

- Posts: 147

- Joined: Fri Jan 15, 2010 7:32 pm

Re: Who are we/What do we do

Thanks for posting that, nice to see some details.

When you get time can you touch on the electronics and software? I thought I had seen both servos and steppers mentioned.

Are they all using Mach 3 or are you doing anything with Linux and CommandCNC?

When you get time can you touch on the electronics and software? I thought I had seen both servos and steppers mentioned.

Are they all using Mach 3 or are you doing anything with Linux and CommandCNC?

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

We do use both stepper and servo and both mach and Linux as well as a new control from Thermal Dynamics that uses motors with the amp cards built in. The Mach version has the most flexibility and most options of any control on the market. However it does rely on a windows based machine. Where this classically causes conflict is when the setup is not right or the user installs web based or software that pings a server when it starts up.

A good Mach install will not use any network safe guards and will be a ultra basic and very minimalistic optioned windows. Mach used to rely on the PC to make step and direction (same for servo and stepper) and would require a robust data stream from the CPU to the port (parallel 25 pin to obtain direct signals without multiplexing the signals). This meant windows XP not 7, not 8, not 10. Then there was an advancement in Mach that Tom from CandCNC and Art (who came out of retirement) made to allow the use of high speed Ethernet and a fast THC and newer windows although many MFGs including Cincinnati laser and Mitsubishi Laser still use Windows XP in the background. This put the step and direction away from the PC opening up speed and capability. Not only that but with the MarkIV or DTHCIV the torch height control was also moved away from Mach controlling the torch. We had Sanborn air compressors send us a test. It was a test of a .990 hole +/- .010 on the outside side of a tank bulk end. So the torch had to react at 120ipm to changes in motion at a couple hundred inches a minute of cut speed on a small hole in 12 ga using 45amps. They told us we were the only MFG that actually passed the test. We have engineered our Star Labs to cut at book speeds. The difference between a servo and a stepper on a Star Lab would be a 45% increase in rapid speed from point to point. There is no other real world appreciable advantage fro plasma cutting.

Linux is very very good. Its plasma functionality is supreme. Youll see Linux make cuts and move from event to event faster than you would see in a Mach system. But Linux does not allow the functionality and other features of Mach right now. For production cutting Linux would be the answer and for the user that would mean limited CAD program availability on the machine.

The Thermal Dynamics iPlasma system is a Windows 7 based touch screen that uses smart servo. We are going to be doing some testing and will showcase a Servo Linux VS and Stepper Mach Vs the Iplasma from Thermal Dynamics. Based on price only the CandCNC electronics are impossible to beat. We have married them to 300amp high frequency/high density plasma cutters with zero issues and in production down to regrettable machines like the Chinese imports (which we REALLY HIGHLY DO NOT RECOMMEND). The most popular and most reliable plasma cutters to date (09/2016) have been the Hypertherm Powermax series.

A good Mach install will not use any network safe guards and will be a ultra basic and very minimalistic optioned windows. Mach used to rely on the PC to make step and direction (same for servo and stepper) and would require a robust data stream from the CPU to the port (parallel 25 pin to obtain direct signals without multiplexing the signals). This meant windows XP not 7, not 8, not 10. Then there was an advancement in Mach that Tom from CandCNC and Art (who came out of retirement) made to allow the use of high speed Ethernet and a fast THC and newer windows although many MFGs including Cincinnati laser and Mitsubishi Laser still use Windows XP in the background. This put the step and direction away from the PC opening up speed and capability. Not only that but with the MarkIV or DTHCIV the torch height control was also moved away from Mach controlling the torch. We had Sanborn air compressors send us a test. It was a test of a .990 hole +/- .010 on the outside side of a tank bulk end. So the torch had to react at 120ipm to changes in motion at a couple hundred inches a minute of cut speed on a small hole in 12 ga using 45amps. They told us we were the only MFG that actually passed the test. We have engineered our Star Labs to cut at book speeds. The difference between a servo and a stepper on a Star Lab would be a 45% increase in rapid speed from point to point. There is no other real world appreciable advantage fro plasma cutting.

Linux is very very good. Its plasma functionality is supreme. Youll see Linux make cuts and move from event to event faster than you would see in a Mach system. But Linux does not allow the functionality and other features of Mach right now. For production cutting Linux would be the answer and for the user that would mean limited CAD program availability on the machine.

The Thermal Dynamics iPlasma system is a Windows 7 based touch screen that uses smart servo. We are going to be doing some testing and will showcase a Servo Linux VS and Stepper Mach Vs the Iplasma from Thermal Dynamics. Based on price only the CandCNC electronics are impossible to beat. We have married them to 300amp high frequency/high density plasma cutters with zero issues and in production down to regrettable machines like the Chinese imports (which we REALLY HIGHLY DO NOT RECOMMEND). The most popular and most reliable plasma cutters to date (09/2016) have been the Hypertherm Powermax series.

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

-

Bigrhamr

- 2.5 Star Member

- Posts: 147

- Joined: Fri Jan 15, 2010 7:32 pm

Re: Who are we/What do we do

Okay, to be sure I understand the Windows/Linux comparison the only drawback to using Linux on the machine control computer would be the inability to use windows based CAD/CAM programs at the machine. I could still use any CAD/CAM to draw and nest on another computer then send G code to the machine control.Would you say that is correct? I am using Hypertherm ProNest LTS for CAM now and love it. Do you have any other customers using it for your machines? I assume they can write a post to work with your controls.

How thick are those gantry end plates? Is the pocket machining on them just for weight reduction?

How thick are those gantry end plates? Is the pocket machining on them just for weight reduction?

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

3/4" thick and pocketed for lightening and strength. We have schools using full Pronest (free for them...heck of a deal). Not sure if there are any other but I am sure there are. I wonder if Max from Dirtbound Offroad is using Pronest yet. He did talk about it

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

-

Bigrhamr

- 2.5 Star Member

- Posts: 147

- Joined: Fri Jan 15, 2010 7:32 pm

Re: Who are we/What do we do

Can you post some details/pics on how your downdraft tables are put together? I see the one pic on the website showing side view with the funnel shaped skirting. Is there a clean out tray or how do you access underneath to clean out scrap and retrieve small parts? I would be looking at a 5'x10' if that makes a difference. Any recommendation for exhaust fan type and size?

Thanks.

Thanks.

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

There is a rather large access door on the front that will allow you to pull or scrape the flat part of the Vee free of parts, scrap or slag droppings. (18x10 IIRC) You will want a sealed exhaust fan. We do not really recommend much for sizing as a policy but a customer sized a 2000cfm fan and that was enough for finecut up to 65amps on the machine. We do have customer that just vent the machine out doors. This is really not the proper way to do it. It is legal right now but not what we would consider proper. The proper method is to filter that air with a properly sized air filter system. That size will change with the maximum cut thickness and amperage of the machine you may be using.

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

-

Bigrhamr

- 2.5 Star Member

- Posts: 147

- Joined: Fri Jan 15, 2010 7:32 pm

Re: Who are we/What do we do

A while back you mentioned doing some testing with the Thermal Dynamics controller. Is that project still in the works? Curious to see how it measures up.

"The Thermal Dynamics iPlasma system is a Windows 7 based touch screen that uses smart servo. We are going to be doing some testing and will showcase a Servo Linux VS and Stepper Mach Vs the Iplasma from Thermal Dynamics."

"The Thermal Dynamics iPlasma system is a Windows 7 based touch screen that uses smart servo. We are going to be doing some testing and will showcase a Servo Linux VS and Stepper Mach Vs the Iplasma from Thermal Dynamics."

- BTA Plasma

- 3.5 Star Elite Contributing Member

- Posts: 632

- Joined: Thu May 12, 2011 4:28 pm

Re: Who are we/What do we do

iPlasma adds significant cost to the machine ($10K+) without adding much or any significant performance over Servo Linux or even more over Stepper Mach. Once you go with this control you are married to the Hudson amplifier integrated motors, you wont use a rotary, router or any other well supported softwares that have been really successful in the entry and mid level markets. So far they have been testing them for a year with what they say is no failure but historically that motor configuration has been a disaster. But if you can imagine taking any cooling fans out of the picture and adding a air cooled heat sink and putting the amplifier right next to the motor your going to have failures. If they come back to us mid to end of next year and tell us they have had no failures then we may be more inclined to be a testing station for the controller. But right now the iplasma is not for us and anyone out there selling it should beware.

If Matt is using this profile he is one of the OGs of Plasma. If not then a technician. We make the worlds fastest and largest CNC plasma tables up to 10x40. www.StarLabCNC.com  Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/

Check out our Facebook page where we update frequently. https://m.facebook.com/StarLabcnc/