exapprentice wrote:Hi motoguy

I agree 100% with your methodology, but, how is your original problem with the cuts working out, have you found the cure or done anymore cutting since your last set of pictures and write up

Really curious to know what the problem is / was just to add it to my knowledge for future referance

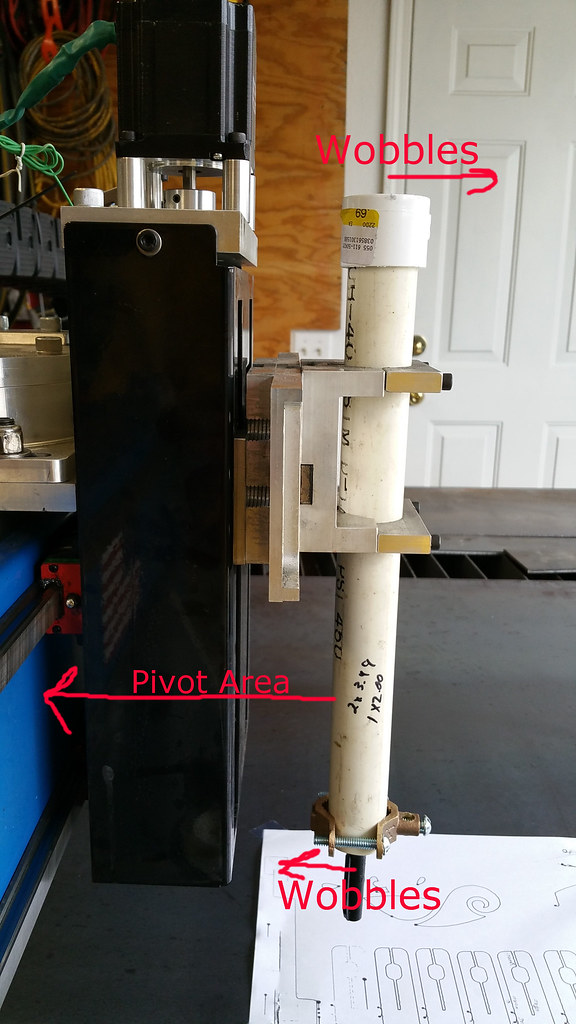

Problem was gantry twist/flex. Looks like I (unwittingly) helped uncover a rigidity issue with the new-style gantry:

http://www.bulltear.com/forums/showthre ... -Owners%29

I received one of the first tables built with the new gantry/Z-axis upgrade, and I believe it was the first one built with a >4' gantry (I have a 6' gantry). I suspect the issue was mitigated with the 4 foot gantry, but the extra 50% of length in the 6' unit added some extra flex. Either way, once determining the source of the problem, Matt decided to offer the rigidity-enhancing gussets (actually, part of the router-support package he offers) to ALL owners of the new style gantry, for FREE. He even covers postage. All new tables come with the gussets pre-installed from the factory.

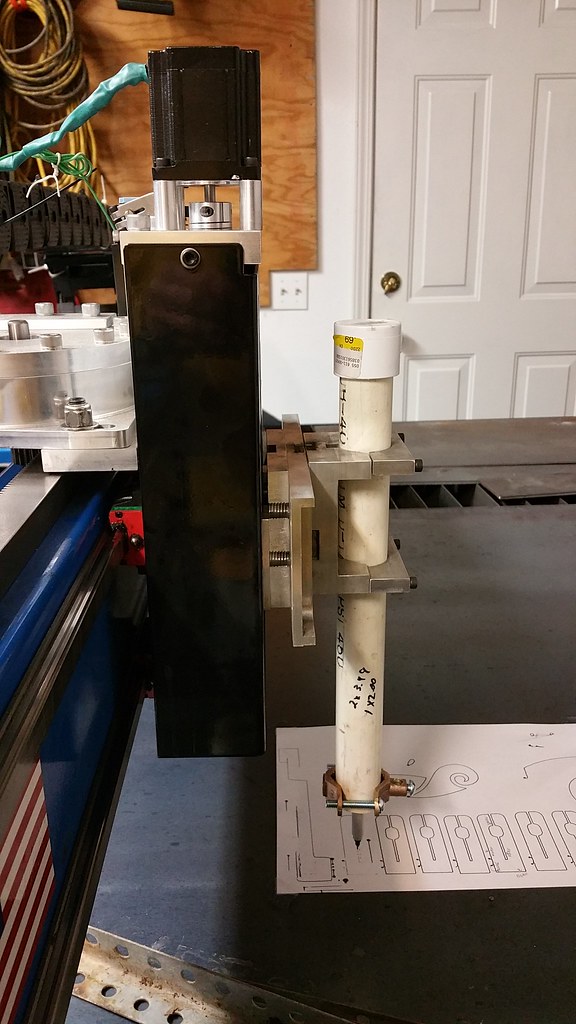

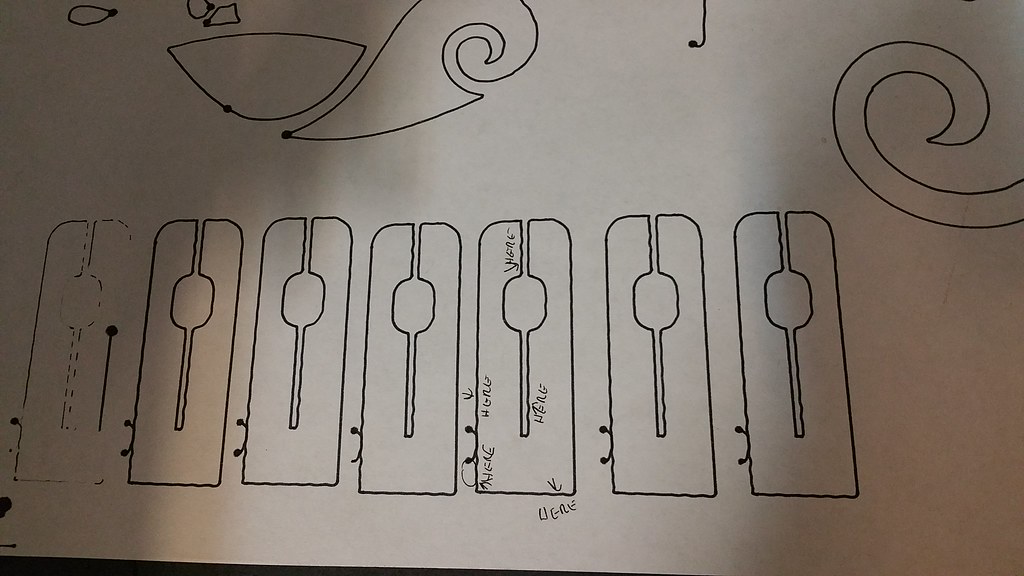

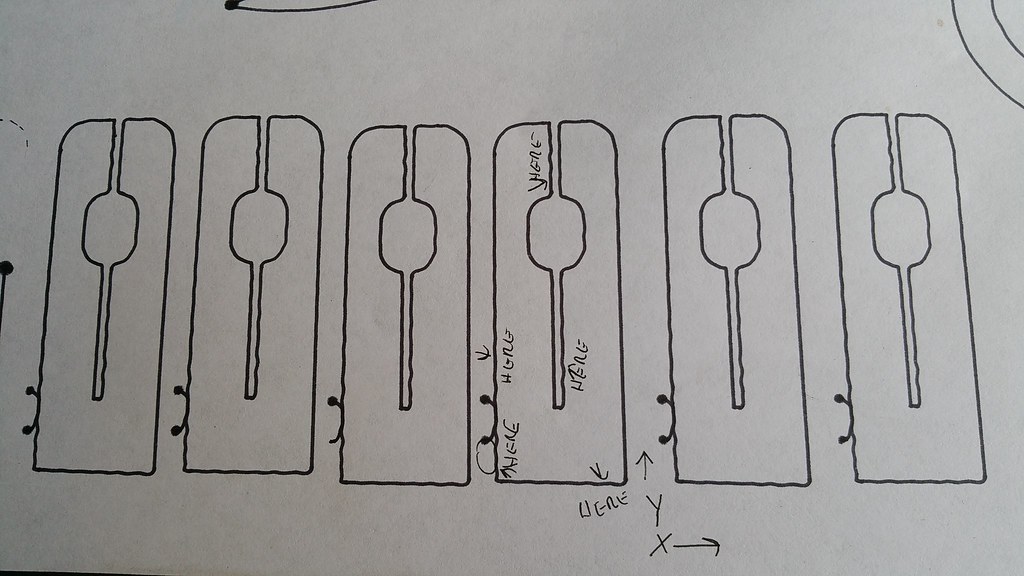

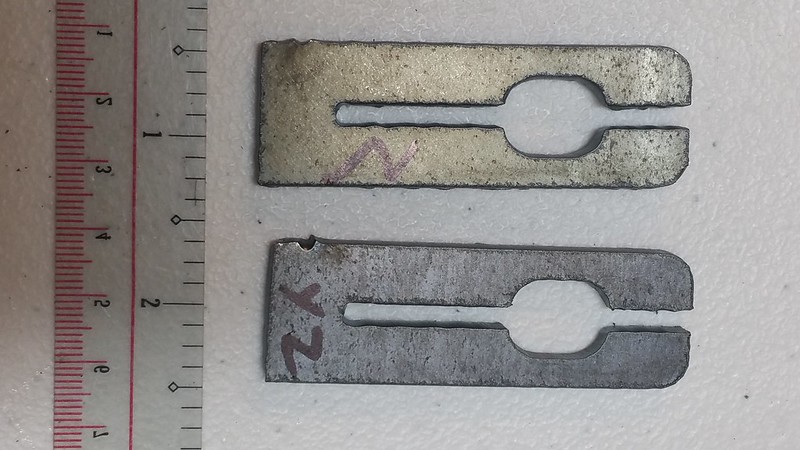

I've since received the support brackets from Matt, and they've made a world of difference. I've yet to run the "finger test" (part I was cutting/drawing earlier in the thread), but I will. I'm back up to running at an accel setting of 30, and it's making beautiful cuts. I actually made my first parts sales this week, and the customer was ecstatic (on 14 ga at 270 IPM). Matt has even offered some additional input on ways to further strengthen the gantry, but this falls in the "overkill" area. The gantry should be sufficiently strong for routing, with the install of these gussets. Now, I'll probably go ahead and put the other recommendations into effect, because I'm "that guy" (see the "I grounded my table, even though I was having no EFI issues" stuff above).

I should probably add that the additional knowledge I've gained on cuts, rules, speeds, lead in/lead out, etc have probably helped to mitigate the situation as well.

Long story short...I'm disappointed I encountered an issue with my new table, but this is EXACTLY why I went with a Bulltear/Starlab, over some of the other brands I considered. I looked at a lot of forums/posts regarding tables and owners, and NO WHERE did I find anything but praise for Matt and Bulltear/Starlab. In addition to creating a great product, he offers OUTSTANDING post-sale support. I am probably "that customer", that wants everything to be "just perfect". I have no doubt that upon reading a couple of my e-mails, Matt was shaking his head, and uttering "you GOTTA be kidding me" (in his MN accent...which makes me smile!). Yet, he never offered anything other than answers to my questions, as well as support, tips, advice, and help. He's been very...accommodating of me, a relatively PITA, OCD customer.

In all fairness, I've seen posts from users of other highly-regarded tables with similar problems (I remember a PlasmaCam owner, specifically). So, occasionally, even the best equipment hits a snag. Besides...this was a new revision/update. I'm typically a firm believer in not being an "early adopter" of...well...anything, really. This is why I tell my wife she can have her new 2016 Pilot as a 2017 model...to let the bugs get worked out of the new offering.

Long story short: Found a bug with the new design. Bug corrected in a prompt, courteous, friendly (and free!) manner by Matt at Bulltear/Starlab.