Cutting Height - Its a BIG deal

Posted: Wed May 06, 2020 1:20 pm

As the title implies your cutting height is critical and will make all the difference in the world with regards to achieving a squarer cut edge and better cut quality overall. Some of you may have a THC (torch height controller) and some of you may not, either way you need to do your very best to be sure your cutting at or close to the manufacturers specified cut height. Correct cutting height will be different from one manufacturer to the next, so check your manual for the recommended height for your plasma cutter and adhere to it.

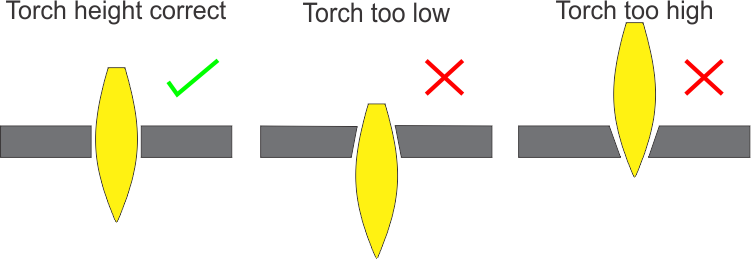

Below is an image depicting the effects of cutting too high, too low, and at the correct height. Notice how cutting too high or too low can cause an excessive positive or negative taper on both sides of the arc. As exaggerated as this depiction may be it does a good job of displaying the effects of incorrect height and what to look for.

Cutting height is not a 1 size fits all kind of thing. Manufacturers will often specify a different cutting height for low and high amperage cutting, shielded and un-shielded consumables, and for different material types being cut. For this reason it is important to refer to your manufacturers cut charts for the recommended height based on what your cutting, and what consumables you plan to use. Cut charts for Hypertherm can be found here Hypertherm Charts and for Thermal Dynamics here Thermal Dynamics Charts Most lower cost hand held plasma cutters will not have charts available since they were designed for low precision hand held cutting where speed and height cannot be controlled accurately. For these systems you can develop your own charts by experimentation and documentation.

To measure your cut height I find feeler gauges work best. You can stack them up to the appropriate thickness and easily slip them between the torch and the work piece while the machine is paused. Do not pause the machine during a small profile such as a hole, or on a radius, or sharp corner, choose a long straight stretch to pause the machine and then check. Often your best to simply draw a straight line and pause midway to do the check before even starting to cut the actual job, particularly if you are a new user and just getting accustomed to your machine. Be sure to always start with new consumables when checking your cut height.

Although the cut height is measured from the end of the nozzle or shield to the work piece, what we are actually setting is the arc length which is the distance between the end of the electrode and the work piece. As the electrode wears it will get shorter and your arc length will increase. If you have a THC (torch height controller) it will adjust the torch height automatically as the electrode wears providing you with more consistent results. Without a THC you will need to monitor your cut edge for the taper shown in the diagram above and reduce the cut height slightly as the electrode wears to achieve more consistent results.

Setting your cut height properly does not mean that you will never see a tapered edge on your cut. A tapered edge can happen for other reasons such as worn consumables, incorrect cut direction, incorrect cut speed, and more, but if you set your height properly you can be sure that's not the issue and look for other problems.

Good luck and have fun

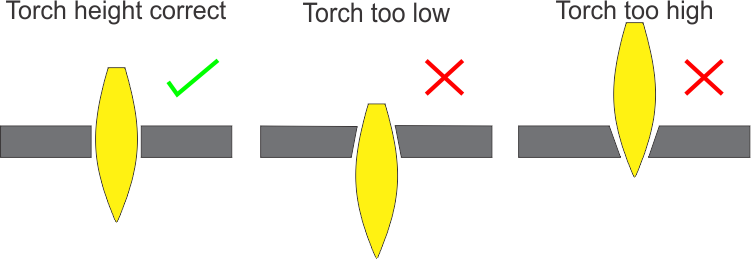

Below is an image depicting the effects of cutting too high, too low, and at the correct height. Notice how cutting too high or too low can cause an excessive positive or negative taper on both sides of the arc. As exaggerated as this depiction may be it does a good job of displaying the effects of incorrect height and what to look for.

Cutting height is not a 1 size fits all kind of thing. Manufacturers will often specify a different cutting height for low and high amperage cutting, shielded and un-shielded consumables, and for different material types being cut. For this reason it is important to refer to your manufacturers cut charts for the recommended height based on what your cutting, and what consumables you plan to use. Cut charts for Hypertherm can be found here Hypertherm Charts and for Thermal Dynamics here Thermal Dynamics Charts Most lower cost hand held plasma cutters will not have charts available since they were designed for low precision hand held cutting where speed and height cannot be controlled accurately. For these systems you can develop your own charts by experimentation and documentation.

To measure your cut height I find feeler gauges work best. You can stack them up to the appropriate thickness and easily slip them between the torch and the work piece while the machine is paused. Do not pause the machine during a small profile such as a hole, or on a radius, or sharp corner, choose a long straight stretch to pause the machine and then check. Often your best to simply draw a straight line and pause midway to do the check before even starting to cut the actual job, particularly if you are a new user and just getting accustomed to your machine. Be sure to always start with new consumables when checking your cut height.

Although the cut height is measured from the end of the nozzle or shield to the work piece, what we are actually setting is the arc length which is the distance between the end of the electrode and the work piece. As the electrode wears it will get shorter and your arc length will increase. If you have a THC (torch height controller) it will adjust the torch height automatically as the electrode wears providing you with more consistent results. Without a THC you will need to monitor your cut edge for the taper shown in the diagram above and reduce the cut height slightly as the electrode wears to achieve more consistent results.

Setting your cut height properly does not mean that you will never see a tapered edge on your cut. A tapered edge can happen for other reasons such as worn consumables, incorrect cut direction, incorrect cut speed, and more, but if you set your height properly you can be sure that's not the issue and look for other problems.

Good luck and have fun