Cutting Direction - CW or CCW and when

Posted: Tue May 05, 2020 3:54 pm

When plasma cutting, one side of the plasma arc will produce a squarer cut than other side. For this reason we want to be sure we are cutting in the appropriate direction, clockwise or counter clockwise (CW or CCW). By selecting the appropriate direction of travel we can be sure the side of the arc producing the squarest cut is cutting on the finished edge of the part, and that the side producing the tapered cut edge is cutting on the waste side of the part.

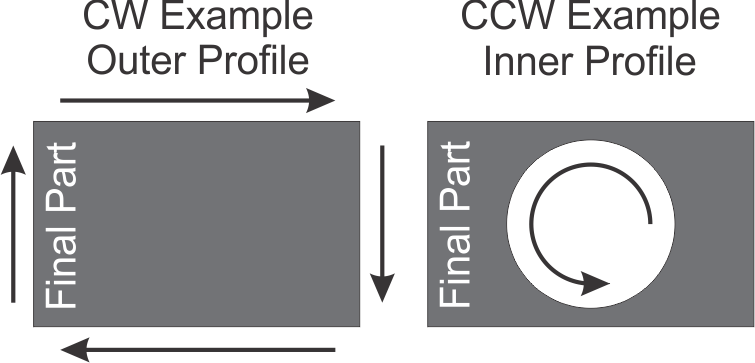

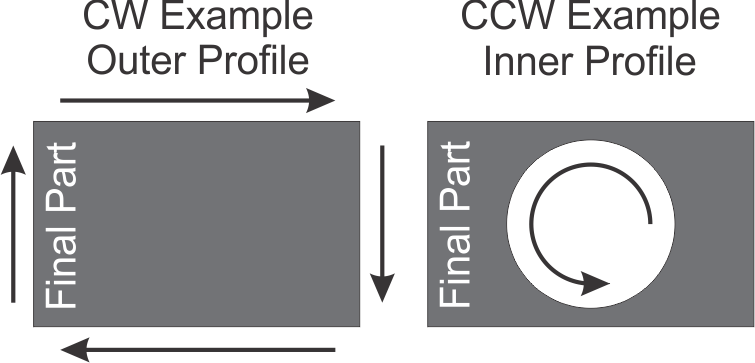

The easiest way to remember this is to imagine standing in front of your plasma table with the torch cutting a straight line away from you. The squarest cut edge will be on the right side of the arc, and the tapered edge will be on the left, just remember that "the right side of the arc is the right side to cut with". With this in mind you can determine if you should be traveling CW or CCW for your inside and outside cut profiles. CW direction will used for outer profiles, and CCW will be used for inner profiles such as hole inside a plate. The thicker the material your cutting, the more pronounced and obvious the taper will be, but make it a habit to set the direction properly no matter what your cutting.

If you set your cut direction properly it does not mean that you will never see a tapered edge on your cut. A tapered edge can be happen for other reasons such as worn consumables, incorrect cut height, incorrect cut speed, and more, but if you set your direction properly you can be sure that's not the issue and look for other problems.

Many new operators will ignore simple things like this figuring it can't make that big a difference, but it all adds up. If you do this wrong and combine it with another issue, then something else comes up, next thing you know your frustrated, having no fun, and running in circles trying to figure out what's wrong. Many modern tables/software packages will take cut direction into account and set it appropriately, however it never hurts to check if you are unsure.

Good luck and have fun

The easiest way to remember this is to imagine standing in front of your plasma table with the torch cutting a straight line away from you. The squarest cut edge will be on the right side of the arc, and the tapered edge will be on the left, just remember that "the right side of the arc is the right side to cut with". With this in mind you can determine if you should be traveling CW or CCW for your inside and outside cut profiles. CW direction will used for outer profiles, and CCW will be used for inner profiles such as hole inside a plate. The thicker the material your cutting, the more pronounced and obvious the taper will be, but make it a habit to set the direction properly no matter what your cutting.

If you set your cut direction properly it does not mean that you will never see a tapered edge on your cut. A tapered edge can be happen for other reasons such as worn consumables, incorrect cut height, incorrect cut speed, and more, but if you set your direction properly you can be sure that's not the issue and look for other problems.

Many new operators will ignore simple things like this figuring it can't make that big a difference, but it all adds up. If you do this wrong and combine it with another issue, then something else comes up, next thing you know your frustrated, having no fun, and running in circles trying to figure out what's wrong. Many modern tables/software packages will take cut direction into account and set it appropriately, however it never hurts to check if you are unsure.

Good luck and have fun