New kid on the block

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

New kid on the block

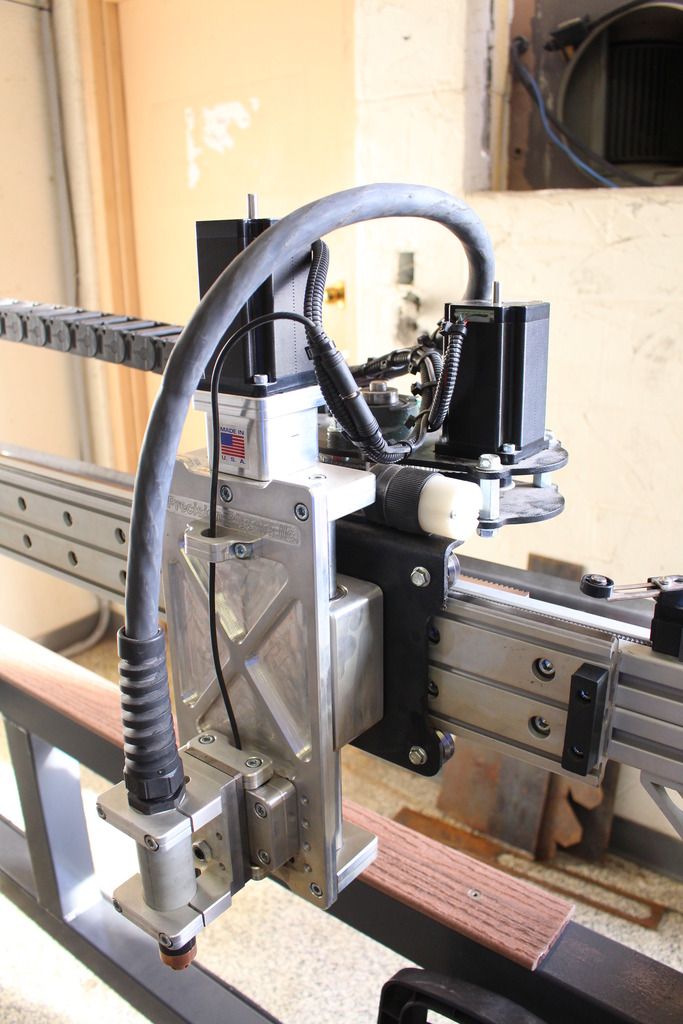

short video that ill use as kind of my intro. i also kinda just wanted to use this spot as a build thread and mark my progress as i go.  https://youtu.be/BHhfQjQhgXA

https://youtu.be/BHhfQjQhgXA

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

Last edited by ranger#1 on Thu Jul 14, 2016 11:32 pm, edited 1 time in total.

-

Greolt

- 2.5 Star Member

- Posts: 112

- Joined: Mon May 18, 2015 12:36 am

Re: New kid on the block

Was curious enough to look at your youtube video, but alas it is locked for private viewing.

WOOPS: Take that back. It now is accessible.

WOOPS: Take that back. It now is accessible.

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

god dam new guy get you shit together...... sorry about that

edit: it says its public so?

edit: it says its public so?

- steel 35

- 3.5 Star Member

- Posts: 634

- Joined: Sun Jan 11, 2015 11:12 am

- Location: N of Cali.

Re: New kid on the block

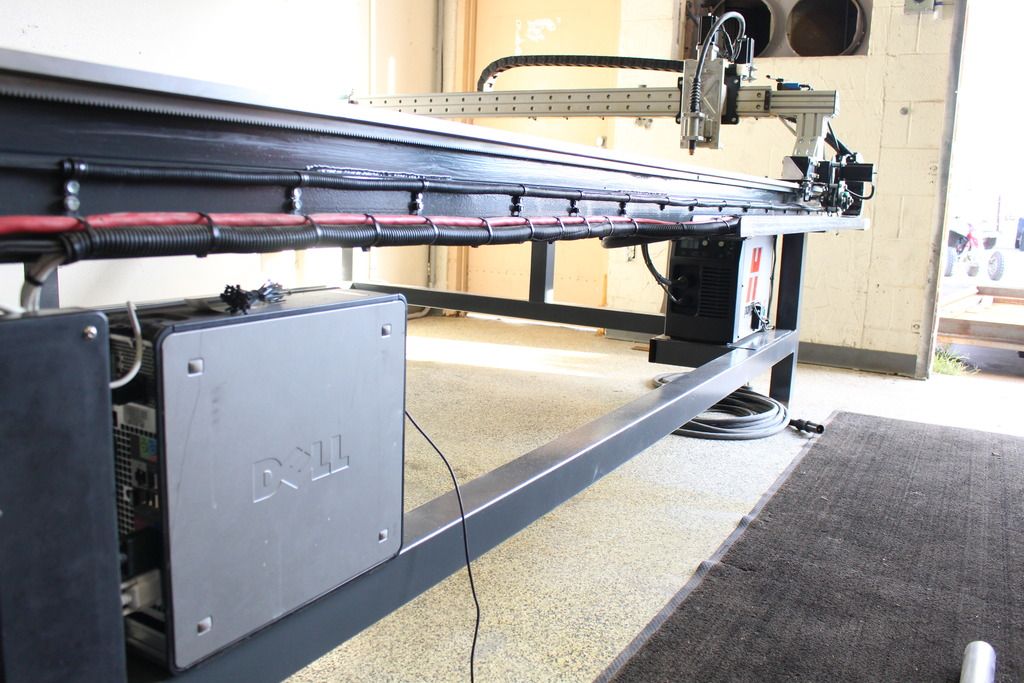

All your Electronics $$$ are right on the edge of the water table.

Mine spills / splashes over very frequently

Mine spills / splashes over very frequently

PPL HDG 4X8

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber

- Capstone

- 4 Star Member

- Posts: 1015

- Joined: Fri Sep 13, 2013 8:42 am

- Location: Washington D.C. Metro

- Contact:

Re: New kid on the block

Yeah, I'd recommend building a rolling cart of some kind that gets the electronics just a little further away from your table.steel 35 wrote:All your Electronics $$$ are right on the edge of the water table.

Mine spills / splashes over very frequently

Otherwise the table looks good. contrats

Phil

It's all relative...

CNC Metal Design

Instagram CNC Metal Design

JD Squared 4x8

HT PM45, Miller 251 MIG

It's all relative...

CNC Metal Design

Instagram CNC Metal Design

JD Squared 4x8

HT PM45, Miller 251 MIG

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: New kid on the block

On your first video, I'd suggest slowing down your Z axis. It sounds like you're losing steps, either due to binding or moving the z faster than the motor can handle.

Your second video, I don't have anything for you right now, I'll have to think on it some.

Steve

Your second video, I don't have anything for you right now, I'll have to think on it some.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: New kid on the block

Double post for some reason.

Steve

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

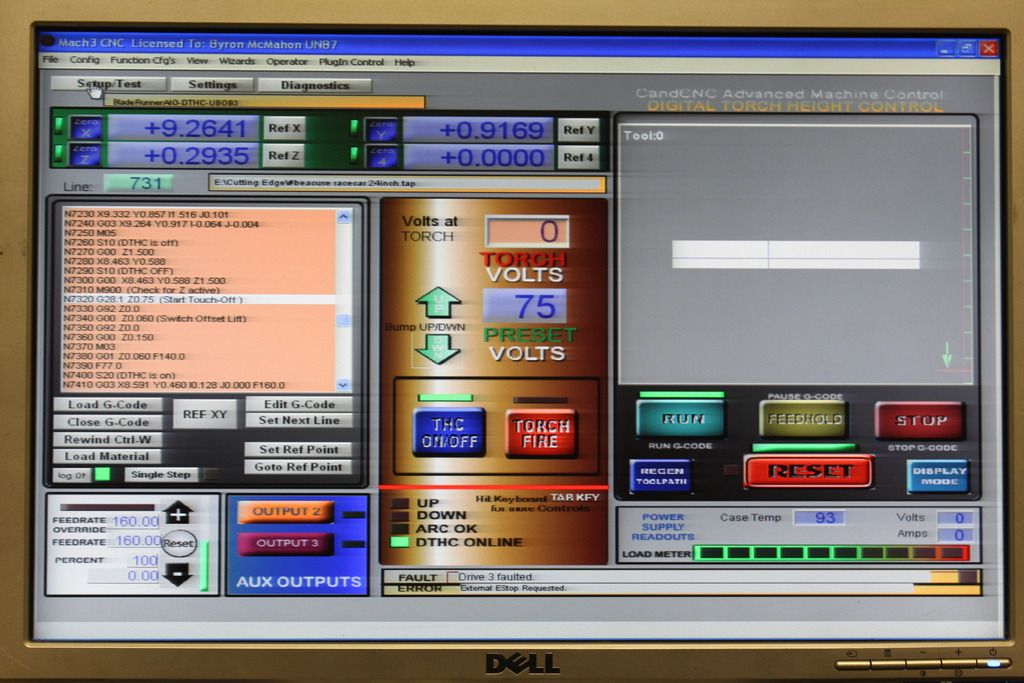

Also some more food for thought, as of late i keep getting a hard external estop from a drive 3 fault. I clear the drive fault hit the reset and im back going. no idea why also seems random/weird. If i rember corectley drive 3 is my z axis correct? or is it my slave to the y azis?

- little blue choo

- 4 Star Member

- Posts: 1461

- Joined: Mon Mar 02, 2015 10:38 pm

- Location: Cherryville NC

- Contact:

Re: New kid on the block

First time seeing language like this on here. Ranger#1 you may talk like this around your wife and kids but don't do it around ours. Yes some of us have family who read this forum also. I suggest you clean your act up and become a useful member or quietly slither away.

Rick

Rick

Rick

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8163

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: New kid on the block

There are a few things you need to look into, one why when you have the magnetic mount dis-locate it does not stop movement with an error.

You may need to add a switch to trigger when the torch uncouples.

Are your motor cables shielded and the shield attached to a common ground at the controller end?

The video shows the Z is loosing it's position and that is why it crashes into the metal at the next start of cut operation.

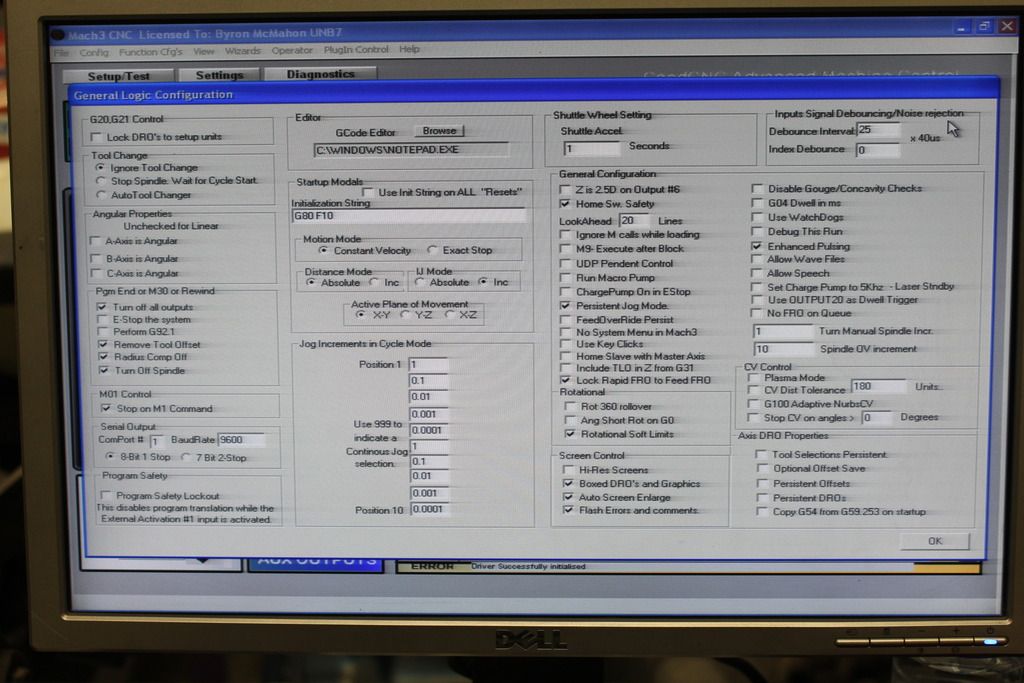

Yes the Z would be drive 3 and it would not be slaved. When you have an error look on the diagnostic page to see what the actual error is, if nothing is showing it is caused by noise. Look on the General config page at the inputs signal debounce/noise rejection and sett both to 5000 that may help.

E-stop and home/limits will show on the diagnostic page in different locations it they are causing the problem find out why (broken wire, bad switch)

You may need to add a switch to trigger when the torch uncouples.

Are your motor cables shielded and the shield attached to a common ground at the controller end?

The video shows the Z is loosing it's position and that is why it crashes into the metal at the next start of cut operation.

Yes the Z would be drive 3 and it would not be slaved. When you have an error look on the diagnostic page to see what the actual error is, if nothing is showing it is caused by noise. Look on the General config page at the inputs signal debounce/noise rejection and sett both to 5000 that may help.

E-stop and home/limits will show on the diagnostic page in different locations it they are causing the problem find out why (broken wire, bad switch)

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

rick, while i respect your opinion, we are all brothers here no need to have any animosity. Rember "curse words" are just a form of self expression. you say "dang it" i say "dam it"... you say "darn thing" i say "god dam pile of shit".I love this site, we are in it together, twards the same goal. if your worried about the wife and kids reading some "non socially accepted words" on the internet i can promise you there is way worse out there. As they say in Ireland, cheers fucker lollittle blue choo wrote:First time seeing language like this on here. Ranger#1 you may talk like this around your wife and kids but don't do it around ours. Yes some of us have family who read this forum also. I suggest you clean your act up and become a useful member or quietly slither away.

Rick

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

- little blue choo

- 4 Star Member

- Posts: 1461

- Joined: Mon Mar 02, 2015 10:38 pm

- Location: Cherryville NC

- Contact:

Re: New kid on the block

I can see you have no respect for others nor yourself. So I will not bother with you. You will find that you will get a lot more help from people here if you conduct yourself like a gentlemen. I have already spoken to several who said they didn't like your use of mother f----r or GD and wouldn't help you if you were the last person on here. So man up and change your use of this forum or see how many continue to help you. Heck you may even get kicked off the forum according to the rules and regulations I had to read to join.

Rick

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

dang that sucks, if i had the opportunity to help someone in need that walked into my shop i would! regardless of age, weight, religion , or even if they were voting for Hillary,  lol and i certainly wouldn't send someone on down the road because of there choice of words

lol and i certainly wouldn't send someone on down the road because of there choice of words  . Why ? because were all different people from different backgrounds, who am i to judge?. picture this, you pull over on the side of the road to help an old lady with a flat tire and she says the " i dont know ,fucking thing just went flat" would you just drive off? no of course not. but enough off all that , i guess im just used to forums that dont care. i get it ... ill try to curve it a bit for you folks

. Why ? because were all different people from different backgrounds, who am i to judge?. picture this, you pull over on the side of the road to help an old lady with a flat tire and she says the " i dont know ,fucking thing just went flat" would you just drive off? no of course not. but enough off all that , i guess im just used to forums that dont care. i get it ... ill try to curve it a bit for you folks

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

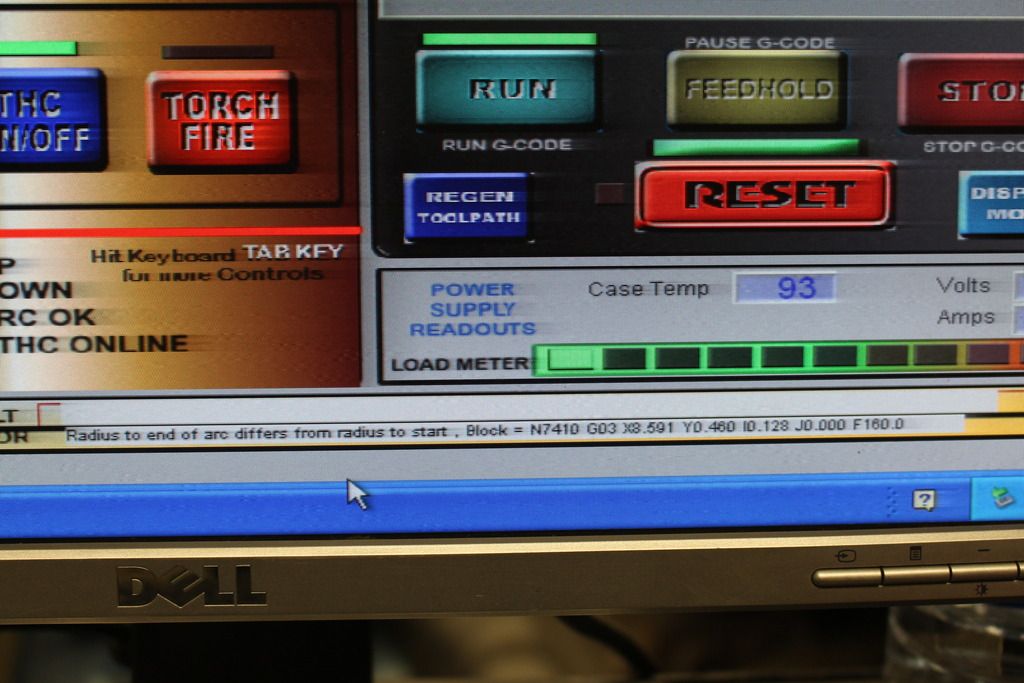

ok so, i changed the above values to 5000 as advised because i figured one thing at a time and gave her hell. this is what i got halfway through a pieceacourtjester wrote:There are a few things you need to look into, one why when you have the magnetic mount dis-locate it does not stop movement with an error.

You may need to add a switch to trigger when the torch uncouples.

Are your motor cables shielded and the shield attached to a common ground at the controller end?

The video shows the Z is loosing it's position and that is why it crashes into the metal at the next start of cut operation.

Yes the Z would be drive 3 and it would not be slaved. When you have an error look on the diagnostic page to see what the actual error is, if nothing is showing it is caused by noise. Look on the General config page at the inputs signal debounce/noise rejection and sett both to 5000 that may help.

E-stop and home/limits will show on the diagnostic page in different locations it they are causing the problem find out why (broken wire, bad switch)

so i cleared the estop, re referenced my z, said alittle prayer, hit the big green magic button and i got this.... not exactly what i prayed for lol

- little blue choo

- 4 Star Member

- Posts: 1461

- Joined: Mon Mar 02, 2015 10:38 pm

- Location: Cherryville NC

- Contact:

Re: New kid on the block

[quote i guess im just used to forums that dont care. i get it ... ill try to curve it a bit for you folks  [/quote]

[/quote]

That would be appreciated.

Rick

That would be appreciated.

Rick

Rick

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

Arclight 9600 4x8 table

Hypertherm PM65

Acc. Plate Marker, 4 inch Pipe Cutter, Wood Router package

Quincy Q54 compressor 2 stage, 5hp, 60 gal

Refrigerated air dryer & 4 stage filtration system

Software Mach 3, Sheetcam, Solid Edge 2D, Inkscape

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8163

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: New kid on the block

The Z failure is very odd I can run G-codes all day long without any motor attached and Mach does not care. Yours is acting like you are running a servo motor which I can see you are not. Looking at the line count on the screen you are well into the G-code so I don't think there is a software switch that is effecting you system. I think you have an electronics problem which is causing a false signal for the first error shown. For the second error line 7410 you may email Les and ask him why that happens or google it which will bring up any post on the web about it. That looks like a software conflict at the end of a cut routing. Like it is trying to cut a closed item where the ends are not going to meet you could look closely at that cut in SheetCam to see if that is what is going on. If you look at the part and cannot move the start point around it is open.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

ranger#1

- 1 Star Member

- Posts: 19

- Joined: Tue Nov 03, 2015 2:24 am

Re: New kid on the block

think i got her whipped. i didn't know if you try to accelerate your steppers too hard they will go into a "rotor lock" situation. even in a rotor lock situation 9 times out of 10 the motor will not draw enough amps to trigger the motor driver fail safe. i de tuned my z-axis and all is well, so far... Holly shit what a learning curve.

-

tcaudle

- 4 Star Elite Contributing Member

- Posts: 1513

- Joined: Tue Feb 28, 2012 6:47 pm

Re: New kid on the block

That unit has current overload on each driver. If you get a dive fault on the same drive then its because that drive power has seen a current spike of over 6A. Since the max it should see in normal operation is no more than 4 something is causing the spike. In DTHC mode (with MACH running the Z with the THC calling the UP and DOWN moves there is NO acceleration curve applied (assuming the moves are all very short and rapid) . A stepper motor will stall (lose steps) if you try to move a load too quickly or at too high an RPM . Since you cannot set the acceleration in MACH for the THC moves you have to slow the THC response RATE. Its in the Settings tab . Its a percentage of Z velocity (motor tuning) so Lower they inneract. Lower it by 20% and if it stops you have your solution. Also depending on the TPI of your Z your overall velocity on Z may be a too high. The nuts on the leadscrew are definite RPM limits. Running lots of fast moves over time cause them to overheat and that will cause binding. If you have the 5TPI (10,000 steps per unit) then about 120 IPM is the top Z speed you can expect. To be safe do not exceed 100. For A 10 TPI its only about 60IPM.

Random driver faults on the same axis come from that axis being overloaded for some amount of time.

Finally its not a good idea to have the control PC in physical contact with the table structure. ANY noise on the table (even if its gounded) has a direct conduit to logic ground (PC ground) and can cause problems. Shielding is only as good as the shield (most shielded cables are for low level shielding of high freq signals.) If you have noise on your signal ground and you tie the shield to that it acts as a long wire antenna! What that means is they would keep the hi-freq signals OFF of your motor wires but do very little to block the low frequency PWM signals come OUT of the motor wires.

Keep your Z leadscrew lubed. Don't run signal or motor wires in parallel (within several inches) over any linear distance with the plasma (torch ) wires. Keep the table side ground separate from the logic (PC side) ground.

water and voltage / electronics do not mix well. Never put your PC or controller in a position where water can make ingress. Damage from water or lightening is not covered by warranty.

Random driver faults on the same axis come from that axis being overloaded for some amount of time.

Finally its not a good idea to have the control PC in physical contact with the table structure. ANY noise on the table (even if its gounded) has a direct conduit to logic ground (PC ground) and can cause problems. Shielding is only as good as the shield (most shielded cables are for low level shielding of high freq signals.) If you have noise on your signal ground and you tie the shield to that it acts as a long wire antenna! What that means is they would keep the hi-freq signals OFF of your motor wires but do very little to block the low frequency PWM signals come OUT of the motor wires.

Keep your Z leadscrew lubed. Don't run signal or motor wires in parallel (within several inches) over any linear distance with the plasma (torch ) wires. Keep the table side ground separate from the logic (PC side) ground.

water and voltage / electronics do not mix well. Never put your PC or controller in a position where water can make ingress. Damage from water or lightening is not covered by warranty.