Plate Marker questions

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Plate Marker questions

I've been looking at some of the Plate Marker art projects the last couple of weeks, and it looks like something I'd like to set up. I have a few questions. I've been watching a few YouTube videos of Plate markers, and it appears there are basically two ways of mounting the scribe. 1 way appears that the scribe assembly is mounted to the gantry z axis carriage, and does not move up and down with the torch mount. The 2nd way seems to mount the scribe assembly to the torch mount, and moves up and down with the z axis. I can see moving the scribe up and down on the z axis so you can set it the same height above the plate, no matter the plate thickness. The other way of mounting, I'm not sure of what the advantages to that are, but there must be a reason.

So can someone with a plate marker discuss how they mounted their scribe, and why?

Thanks, Steve

So can someone with a plate marker discuss how they mounted their scribe, and why?

Thanks, Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

check out my $100 plate marker set up http://www.plasmaspider.com/viewtopic.p ... 130#p73130

our bulltear table has tall clearance over the table for various fixtures and a rotary head for tube

the bulltear table has ~9'' of travel in the z-axis, and the gantry sits 12'' above the table

that would make impossible to mount the head on the gantry head, mine is mounted on the z-axis

i still needed a long air slide to keep the engraver clear of fixtures and get it down to the material

we have a mag mount for the torch head, the plate marker mounts behind the mag mount

also have a video on youtube https://www.youtube.com/watch?v=5O8rjZ_ ... e=youtu.be

our bulltear table has tall clearance over the table for various fixtures and a rotary head for tube

the bulltear table has ~9'' of travel in the z-axis, and the gantry sits 12'' above the table

that would make impossible to mount the head on the gantry head, mine is mounted on the z-axis

i still needed a long air slide to keep the engraver clear of fixtures and get it down to the material

we have a mag mount for the torch head, the plate marker mounts behind the mag mount

also have a video on youtube https://www.youtube.com/watch?v=5O8rjZ_ ... e=youtu.be

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8183

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Plate Marker questions

I have mine hooked to the Z axis I don't have the travel that Ogre has because I don't use the plate marker and torch at the same time I have about 2" up/down cylinder to move the plate marker. If I'm doing a small plate I put plywood on the water table clamp the plate to it. The Z axis gives placement of the scribe tip to about 1-1/2" above the metal and the cylinder make the contact to the metal it only takes about 5 PSI but 90 PSI for the scribe.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

Thanks guys, I appreciate the feedback. One thing I was wondering about is if the single cylinder rotates any as it goes up and down. After looking at acourtjester's setup I'd say the answer is yes, as it appears he has a rail set up to keep the scribe from turning. I'm also concerned about adding weight to the Z axis, and acourtjester's mount looks pretty lightweight.

All good things to think about as I progress on the design and fabrication phase. I'm sure I'll have other questions over the coming weeks, so again, Thanks a Lot.

Steve

All good things to think about as I progress on the design and fabrication phase. I'm sure I'll have other questions over the coming weeks, so again, Thanks a Lot.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

plain ol Bill

- 3.5 Star Elite Contributing Member

- Posts: 689

- Joined: Fri Aug 15, 2008 6:22 pm

- Location: Tenino,WA

Re: Plate Marker questions

the one I built (and now belongs to OldSarge) is on the Z axis and floats above the tip level of the torch. When activated by M command the cylinder drives it down below the torch level to engrave. Engrave first then cut.

plain ol Bill

Hypertherm 1250

Duramax machine torch

Corel Draw X6

Sheetcam

Mach3

5 x 10 self built table

Lots of ineptitude

Hypertherm 1250

Duramax machine torch

Corel Draw X6

Sheetcam

Mach3

5 x 10 self built table

Lots of ineptitude

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8183

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Plate Marker questions

The cylinder is only for up/down movement the rail keeps the scribe from wondering. Its just like the torch you want to control its position for accuracy. You could use round linear guides but you would need two in parallel as you can see in Ogre's video.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

i use a numatics linear slide, 2 guide bars and a single cylinder

new it would be over $500 (also why the kits are pricey), i found this one on ebay for $29

http://www.numatics.com/common/PDF/shseries.pdf

if your going to make your own i'd base it on what you can find cheap on ebay

search on ebay for: air slide, linear air slide, linear slide or any version of that

most are new stock left over from machine builds, though used would work also

new it would be over $500 (also why the kits are pricey), i found this one on ebay for $29

http://www.numatics.com/common/PDF/shseries.pdf

if your going to make your own i'd base it on what you can find cheap on ebay

search on ebay for: air slide, linear air slide, linear slide or any version of that

most are new stock left over from machine builds, though used would work also

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

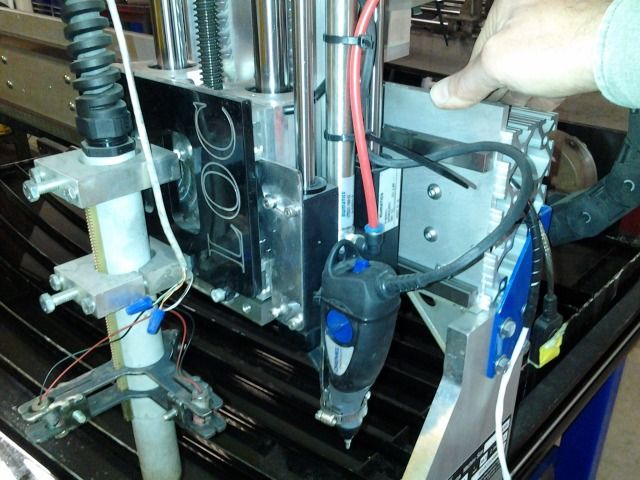

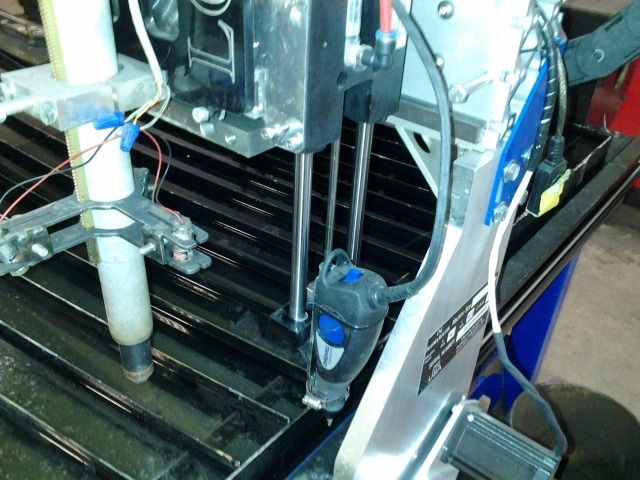

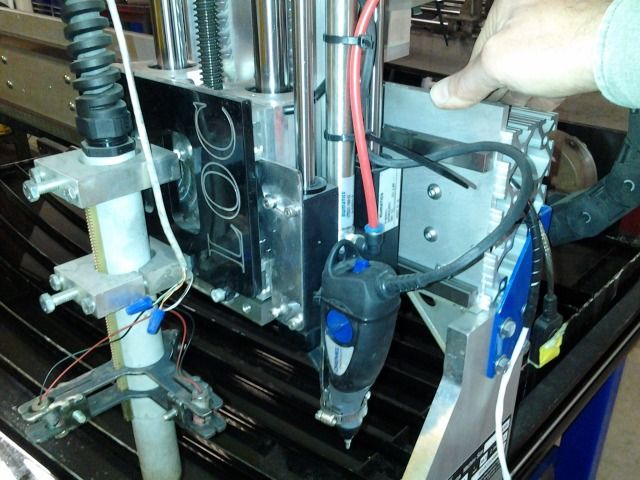

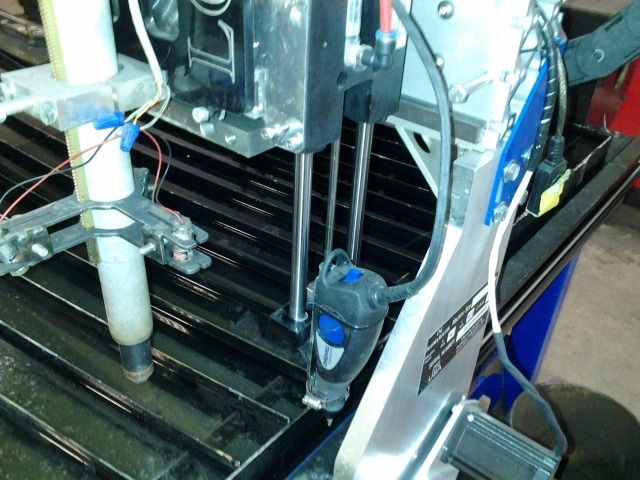

Now that I've got my plate marker working, it's time for pictures and stuff.

Here's a shot of the finished Plate marker from the front and side: And here's the air control setup. What I ended up doing is getting an air valve from the surplus center, which while cheap, was 24 Volt DC, so I made up a power supply for it using a 24 Volt transformer and a bridge rectifier I had laying around from another project. I decided to run the air at 120 psi into the valve, splitting it to 2 air regulators on the normally closed side of the valve, one regulator for the down pressure on the air cylinder, and one to the air scribe (a CP 9361). The normally open side of the valve went to the up pressure on the air cylinder. The air cylinder is a dual rod cylinder I picked up on Ebay. The scribe came from a tool supplier for a decent price.(relative to the cost of the table anyway)

And then a shot of the scribe oiler, which I picked up from the Surplus Center. I took the filter off the end of the scribe hose and put it on the input to the oiler, so I wouldn't running oil thru the filter. I set the scribe up using this document, which was information I copied from various places on the internet. Again, thanks to everyone for your help on this project.

Steve

Here's a shot of the finished Plate marker from the front and side: And here's the air control setup. What I ended up doing is getting an air valve from the surplus center, which while cheap, was 24 Volt DC, so I made up a power supply for it using a 24 Volt transformer and a bridge rectifier I had laying around from another project. I decided to run the air at 120 psi into the valve, splitting it to 2 air regulators on the normally closed side of the valve, one regulator for the down pressure on the air cylinder, and one to the air scribe (a CP 9361). The normally open side of the valve went to the up pressure on the air cylinder. The air cylinder is a dual rod cylinder I picked up on Ebay. The scribe came from a tool supplier for a decent price.(relative to the cost of the table anyway)

And then a shot of the scribe oiler, which I picked up from the Surplus Center. I took the filter off the end of the scribe hose and put it on the input to the oiler, so I wouldn't running oil thru the filter. I set the scribe up using this document, which was information I copied from various places on the internet. Again, thanks to everyone for your help on this project.

Steve

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

grindergary

- 3.5 Star Elite Contributing Member

- Posts: 623

- Joined: Sat Aug 25, 2012 8:08 pm

- Location: Edmonton, Alberta Canada

- Contact:

Re: Plate Marker questions

Thanks for the information,

Gary

Gary

4x8 Home made with Precision Plasma LLC. Gantry

4x8 Home Router made with Precision Plasma LLC. Gantry

Candcnc DHCTII Electronics

Hypertherm Powermax 105 machine torch

Sheetcam, Mach 3

Corel Draw 8, V Carve Pro

Miller CTS 280 Miller Mig

4x8 Home Router made with Precision Plasma LLC. Gantry

Candcnc DHCTII Electronics

Hypertherm Powermax 105 machine torch

Sheetcam, Mach 3

Corel Draw 8, V Carve Pro

Miller CTS 280 Miller Mig

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

nice work wyogreen, the scribe adds a little versatility to the plasma table

i still haven't figured out how to turn off and raise the scribe without manually entering M09 before the last scribe command

otherwise it just drags the scribe across the material to home or drags the scribe along as it goes into plasma mode

on the plus end, i hit a yard sale last weekend. there on a shelf was an air scribe. i asked how much?

she said ''i don't even know what it is, give me a dollar'', i smiled and said ''how about $25''

i don't need anything else to keep me awake at night

i still haven't figured out how to turn off and raise the scribe without manually entering M09 before the last scribe command

otherwise it just drags the scribe across the material to home or drags the scribe along as it goes into plasma mode

on the plus end, i hit a yard sale last weekend. there on a shelf was an air scribe. i asked how much?

she said ''i don't even know what it is, give me a dollar'', i smiled and said ''how about $25''

i don't need anything else to keep me awake at night

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

Ogre, I would have loved to have found a $25 scribe. I did find a $69 dollar one, but when the guy checked it out before shipping, the stylus was broken, so he refunded my money. So I went ahead and bought a new one for $250. Close to your price, just an extra "0" on the end!

As far as the scribe raising up, I just use the newest sheetcam post from CandCNC, and set up the plate marker per the setup instructions for the post. Works like a dream, raises after every scribe'd part.

Good luck on yours, Steve

As far as the scribe raising up, I just use the newest sheetcam post from CandCNC, and set up the plate marker per the setup instructions for the post. Works like a dream, raises after every scribe'd part.

Good luck on yours, Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

ok, now you have my attention

where exactly are you downloading sheetcam post processors?

where exactly are you downloading sheetcam post processors?

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- captdick

- 2 Star Elite Contributing Member

- Posts: 64

- Joined: Mon Dec 21, 2009 11:13 am

- Location: Lodi, Wisconsin

Re: Plate Marker questions

My question too. I only want to change post processor for scribe. When I change post to Mp 1000 thc scribe it changes for all previous tools. Do I have to change post each time I want to use tool.

In other words how do you set up different post processors for different tools so you don't have to change then once set up---Thanks

I tried to run my old tools with the MP 1000 thc scribe post and the don't work.

My old tools work fine once changed back to MP 1000 thc.

I am using an older version of sheet can {3.0.16} I have been reluctant to upgrade to a newer version when all is working well.

In other words how do you set up different post processors for different tools so you don't have to change then once set up---Thanks

I tried to run my old tools with the MP 1000 thc scribe post and the don't work.

My old tools work fine once changed back to MP 1000 thc.

I am using an older version of sheet can {3.0.16} I have been reluctant to upgrade to a newer version when all is working well.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 8183

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Plate Marker questions

I way I have my scribe set up is with a spring return cylinder it is internal to the cylinder. I use a 3 way solenoid which only applies air to the cylinder to go down then the solenoid allows the air to the cylinder to bleed back and the spring pushes the scribe up. I also create a tool for the scribe and choose it just like a plasma tool and use the same post processor for both. The scribe is an different operation then plasma. I did the same thing for the drag knife.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

I download the latest post processors off the CandCNC web site. Right now Tom is working on a do everything post. The latest update loads a custom Mach3 screen, and updates the hub utility and the DTHC firmwares. The pdf with the update has instructions for setting up the Sheetcam tool-table for a plate marker, as well as for a plate marker center-punch, and a plasma drill tool to do peck center punches. It all works pretty well, although being new, it has a couple of minor bugs which Tom is working on. The newest post is DTHC-HYT-TAP_SoftPierce+Marker-rev12.scpost, which last time I looked hasn't been posted on the website. I imagine Tom is waiting to post it until he gets the last little bug fixed. There is a link to the post on the CandCNC Support Board.

I used a double-acting cylinder which uses air for the up and down. I set my up pressure to 90 psi (which is max cylinder pressure) to get a fast up, and my down pressure right now I'm running at 40 psi. I wanted to get my down pressure as light as possible to help protect the scribe stylus, but if I go too low, the cylinder is sometimes kinda slow going down. The scribe I run at 90 psi, which is just below it's max pressure. The CP-9361 has an adjustable air valve on the scribe which can also be adjusted to vary the speed of the scribe blows.

When I set my job up in Sheetcam, I put all the scribe and center-punch operations on one contour and run it first. If I have any plasma peck operations, they go on their own contour and run next. Then I do all the other plasma operations on their own contours. All these different operations are done using the same rev12 post, and just use different tools from the tool table.

Steve

I used a double-acting cylinder which uses air for the up and down. I set my up pressure to 90 psi (which is max cylinder pressure) to get a fast up, and my down pressure right now I'm running at 40 psi. I wanted to get my down pressure as light as possible to help protect the scribe stylus, but if I go too low, the cylinder is sometimes kinda slow going down. The scribe I run at 90 psi, which is just below it's max pressure. The CP-9361 has an adjustable air valve on the scribe which can also be adjusted to vary the speed of the scribe blows.

When I set my job up in Sheetcam, I put all the scribe and center-punch operations on one contour and run it first. If I have any plasma peck operations, they go on their own contour and run next. Then I do all the other plasma operations on their own contours. All these different operations are done using the same rev12 post, and just use different tools from the tool table.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

wyogreen... that doesn't answer my where did you download them question?

i've been all over the candcnc site and found nothing

though i did find the pipefit program, anxious to try it out

what speed do you scribe at?

i've tried 50 ipm and the corners aren't as sharp as when i slow down to 30 ipm

i've been all over the candcnc site and found nothing

though i did find the pipefit program, anxious to try it out

what speed do you scribe at?

i've tried 50 ipm and the corners aren't as sharp as when i slow down to 30 ipm

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

Good morning Ogre,

Sorry I wasn't more specific, I'll do better this time around. First off, here's a link to the CandCNC page. For some reason the downloads are on the manuals page. http://www.candcnc.com/manuals.htm. If you scroll down to the bottom of the page, you'll see a bunch of zip files. The bottom 2 probably contain the stuff you're interested in.

I'm running my scribe pretty slow till I'm sure I've got everything working the way I want. I'm only running 20ipm for now till I'm sure I've got my height where I want it, as I'm afraid higher speeds will put more sideways pressure on the stylus if it's too deep. What I've been noticing is that my water table slats are not perfectly level with my gantry, and a very little amount of height difference will make quite a lot of difference on the scribe. My initial thought was I'd put very little down pressure on the scribe and that would let the scribe float to make up for material warp, etc. But if I get down to 5 psi where I wanted, my air cylinder won't reliably come all the way down. I'm kicking around spring loading the air cylinder to see if that will help out my floating scribe idea.

Steve

Sorry I wasn't more specific, I'll do better this time around. First off, here's a link to the CandCNC page. For some reason the downloads are on the manuals page. http://www.candcnc.com/manuals.htm. If you scroll down to the bottom of the page, you'll see a bunch of zip files. The bottom 2 probably contain the stuff you're interested in.

I'm running my scribe pretty slow till I'm sure I've got everything working the way I want. I'm only running 20ipm for now till I'm sure I've got my height where I want it, as I'm afraid higher speeds will put more sideways pressure on the stylus if it's too deep. What I've been noticing is that my water table slats are not perfectly level with my gantry, and a very little amount of height difference will make quite a lot of difference on the scribe. My initial thought was I'd put very little down pressure on the scribe and that would let the scribe float to make up for material warp, etc. But if I get down to 5 psi where I wanted, my air cylinder won't reliably come all the way down. I'm kicking around spring loading the air cylinder to see if that will help out my floating scribe idea.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

i was all over that site and never found that. thank youWyoGreen wrote:For some reason the downloads are on the manuals page.

i will try the new scribe post, i also cleaned out a lot of posts that i will never use

i found that the less speed and air pressure i have the better the scribe.

i have a 6 or 8 inch slide and have some play in the scribe.

i was setup to run 5psi on down pressure, my ebay 0-15psi gauge went bad

so no i adjust the down pressure to where i can easily pick up the scribe

i do not have my slide set to bottom out or rest on the stops

i could probably scribe corrugated roofing

when metering air you meter in (vs metering out on hydraulics)

i have metering valves on both ends of the slide, the valves meter in, free flow out

this way i can run full pressure up and control the speed with the valve, one less regulator

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

Ogre, your comments on air valves got me to thinking about my air regulator set up. I'll bet my down pressure problem is due to my up pressure regulator restricting the free flow of air from the air cylinder, thus slowing down the down direction. I'll have to go out to the shop and do a little testing.....

Thanks, Steve

Thanks, Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

my slide drops pretty fast for having 5 psi down pressure and i control the flow both up and down

youtube video here https://www.youtube.com/watch?v=5O8rjZ_3c_4

my slide is long, i'd like to have the z axis pick up .25'' instead of the slide working up and down

i really need to figure out how to edit post processors

most of my valves and fittings came from ebay seller mettle air

this is what i plugged into the air valve to get to 1/4'' air line

controlled flow one way, free flow the other

the fittings cost $2 the valves $6

how is that $8 air lubricator holding up?

is it adjustable or set on oil usage?

never been to that surplus center site

looks like a good one

youtube video here https://www.youtube.com/watch?v=5O8rjZ_3c_4

my slide is long, i'd like to have the z axis pick up .25'' instead of the slide working up and down

i really need to figure out how to edit post processors

most of my valves and fittings came from ebay seller mettle air

this is what i plugged into the air valve to get to 1/4'' air line

controlled flow one way, free flow the other

the fittings cost $2 the valves $6

how is that $8 air lubricator holding up?

is it adjustable or set on oil usage?

never been to that surplus center site

looks like a good one

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Plate Marker questions

Ogre, the oil lubricator is adjustable. The scribe instructions said 1 drop per minute. I had the oiler set at the mid point, and didn't really notice any drops when I started out. When the scribe started blowing little oil spots, I figured I might have it set a little high. So now I've got it set all the way down hoping to dry the oil out of the line a bit. If I remember right, you use an electric scribe, so you wouldn't get much out of an oiler! (though maybe it would loosen up those electrons some!)

Still haven't got the down pressure to 5 psi, but have managed to get down to 20 psi, so it's better, but not to the floating stage yet. I ended up drilling out the internal passages of the air cylinder to the same diameter as the air line, which made a big difference. I'm thinking maybe move the air regulator closer to the slide. I didn't want the extra weight on the gantry, but maybe the 12' of air line from the regulator to the cylinder is part of the problem. 5 psi probably doesn't flow all that fast in 1/4 inch air line.

If I don't have my z rapid clearance set the same as my z scribe offset, my z axis goes up and down with the scribe, only it lags a little bit, so the scribe has started moving before the z stops. Another reason to get the floating scribe working better. But maybe you could use that to your advantage on your setup. I suppose it depends on your machine setup and post processor.

Still haven't got the down pressure to 5 psi, but have managed to get down to 20 psi, so it's better, but not to the floating stage yet. I ended up drilling out the internal passages of the air cylinder to the same diameter as the air line, which made a big difference. I'm thinking maybe move the air regulator closer to the slide. I didn't want the extra weight on the gantry, but maybe the 12' of air line from the regulator to the cylinder is part of the problem. 5 psi probably doesn't flow all that fast in 1/4 inch air line.

If I don't have my z rapid clearance set the same as my z scribe offset, my z axis goes up and down with the scribe, only it lags a little bit, so the scribe has started moving before the z stops. Another reason to get the floating scribe working better. But maybe you could use that to your advantage on your setup. I suppose it depends on your machine setup and post processor.

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

thanks, i'll try the surplus center oiler, i did find an air scibe at a yard sale a couple weekends ago

look in your tools setup in sheetcam; you can add a start delay to allow the air scribe to make contact

i had to add 1 sec delay to the scribe, it was moving before the scribe was fully down and engaged

i also have a cut height of .9'' so the torch does a touch off and moves up then over to the scriber offsets

i'm making a new scribe mount for the $25 air scribe, moving the scribe closer to the torch

right now i have a 6'' offset, if i try to scribe too close to the edge of a sheet the gantry runs off

oops, newb error

look in your tools setup in sheetcam; you can add a start delay to allow the air scribe to make contact

i had to add 1 sec delay to the scribe, it was moving before the scribe was fully down and engaged

i also have a cut height of .9'' so the torch does a touch off and moves up then over to the scriber offsets

i'm making a new scribe mount for the $25 air scribe, moving the scribe closer to the torch

right now i have a 6'' offset, if i try to scribe too close to the edge of a sheet the gantry runs off

oops, newb error

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Plate Marker questions

keeping this thread going instead of creating a new one

have my new controls setup for the air scribe; one 120v control valve, one air regulator and one airline in the track

down outlet on the valve has a T, straight thru for air scribe and speed valve for air slide down speed into regulator

my ebay 15psi gauge quit so i just set pressure to where i can easily lift the air slide

the new mount for the air scribe cantilevers over to the torch, this keeps the offsets tighter thus i can scribe closer to the edge

the design exaggerates any play in the slide, i'll need to move it back to the center of the air slide. bummer

have my new controls setup for the air scribe; one 120v control valve, one air regulator and one airline in the track

down outlet on the valve has a T, straight thru for air scribe and speed valve for air slide down speed into regulator

my ebay 15psi gauge quit so i just set pressure to where i can easily lift the air slide

the new mount for the air scribe cantilevers over to the torch, this keeps the offsets tighter thus i can scribe closer to the edge

the design exaggerates any play in the slide, i'll need to move it back to the center of the air slide. bummer

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

scriber post problem

i'm having issues with the scriber post; i've tried the MP1000-THC - with scriber post and the Mach3 THC with scriber post. both have the same issue, maybe someone can explain what i'm doing wrong. here is a simple 2 line, by 2 inches gcode .tap file with my comments in [brackets] my z offset is -5mm

N0010 (Filename: junk12.tap)

N0020 (Post processor: MP1000-THC - scriber.scpost) [scriber post shows as [edited] in sheetcam]

N0030 (Date: 13/12/2014)

N0040 G20 (Units: Inches)

N0050 G53 G90 G40

N0060 F1

N0070 (Part: scribe test)

N0080 (Process: No Offset, LINE, T100: Plate marker) [scriber is tool 100]

N0090 G00 X0.0000 Y0.5000

N0100 G28.1 Z0.12 F19.685

N0110 G92 Z0.0

N0120 G00 Z1.3200 [switch offset]

N0130 G92 Z0.0

N0140 G00 Z0.3937 [z axis has always gone to .3937 scribing but i don't know why]

N0150 Y3.4134

N0160 Z0.7031 [.9'' plasma rapid minus 5mm z axis offset][why 2 z axis moves?]

N0170 M08 [plate marker on]

N0180 G04 P1

N0190 G01 X2.0000 F50

N0200 M09 [plate marker off]

N0210 G04 P0.5

N0220 G00 X0.0000 Y2.9134

N0230 M08

N0240 G04 P1

N0250 G01 X2.0000

N0260 G00 Z0.1968 [z axis dives here, no idea why. scribe is still on]

[this is where i manually enter M09 to turn off scribe]

N0270 X0.0000 Y0.0000 Z0.3937

N0280 M05 M30

if i enter over -14mm in z axis offset line N0260 goes negative and torch crashes

i've been editing line N0260 G00 Z0.9 M09 to set z rapid height and turn off scriber

i use M07 for scriber output on, just yesterday figured out if i edit the scriber post and replace all M08 commands with M07 the post changes the gcode correctly.

for the M09 scriber off at the end of the scribing session, the post does not do this automatically in line N0260. it was suggested to edit the post

''For the M09 issue I checked and it is a bug in the post. Look for

function OnPenUp() and change this line:

if(tool > 99) then

to:

if(tool > 99 or toolClass == "MarkerTool") then''

i did that and still didn't work

ALSO... when starting scribing on any arc or circle the Z axis rises from what ever is on line N0160 to z axis rapid height of .9. the rise is even thru the arc or circle; small circle or large z rises evenly thru out the arc distance.

N0010 (Filename: junk12.tap)

N0020 (Post processor: MP1000-THC - scriber.scpost) [scriber post shows as [edited] in sheetcam]

N0030 (Date: 13/12/2014)

N0040 G20 (Units: Inches)

N0050 G53 G90 G40

N0060 F1

N0070 (Part: scribe test)

N0080 (Process: No Offset, LINE, T100: Plate marker) [scriber is tool 100]

N0090 G00 X0.0000 Y0.5000

N0100 G28.1 Z0.12 F19.685

N0110 G92 Z0.0

N0120 G00 Z1.3200 [switch offset]

N0130 G92 Z0.0

N0140 G00 Z0.3937 [z axis has always gone to .3937 scribing but i don't know why]

N0150 Y3.4134

N0160 Z0.7031 [.9'' plasma rapid minus 5mm z axis offset][why 2 z axis moves?]

N0170 M08 [plate marker on]

N0180 G04 P1

N0190 G01 X2.0000 F50

N0200 M09 [plate marker off]

N0210 G04 P0.5

N0220 G00 X0.0000 Y2.9134

N0230 M08

N0240 G04 P1

N0250 G01 X2.0000

N0260 G00 Z0.1968 [z axis dives here, no idea why. scribe is still on]

[this is where i manually enter M09 to turn off scribe]

N0270 X0.0000 Y0.0000 Z0.3937

N0280 M05 M30

if i enter over -14mm in z axis offset line N0260 goes negative and torch crashes

i've been editing line N0260 G00 Z0.9 M09 to set z rapid height and turn off scriber

i use M07 for scriber output on, just yesterday figured out if i edit the scriber post and replace all M08 commands with M07 the post changes the gcode correctly.

for the M09 scriber off at the end of the scribing session, the post does not do this automatically in line N0260. it was suggested to edit the post

''For the M09 issue I checked and it is a bug in the post. Look for

function OnPenUp() and change this line:

if(tool > 99) then

to:

if(tool > 99 or toolClass == "MarkerTool") then''

i did that and still didn't work

ALSO... when starting scribing on any arc or circle the Z axis rises from what ever is on line N0160 to z axis rapid height of .9. the rise is even thru the arc or circle; small circle or large z rises evenly thru out the arc distance.

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

more scriber post

here is a different post gcode with the same problem. note the z axis offset is -15mm on this one

N0010 (Filename: junk10.tap)

N0020 (Post processor: Mach3 THC with scriber.scpost)

N0030 (Date: 12/12/2014)

N0040 G20 (Units: Inches)

N0050 F1

N0060 G53 G90 G40

N0070 (Part: scribe test)

N0080 (Operation: No Offset, LINE, T100: Plate marker)

N0090 G00 X0.0000 Y0.5000

N0100 G28.1 Z0.12 F19.685

N0110 G92 Z0.0

N0120 G00 Z0.0520

N0130 G92 Z0.0

N0140 G00 Z0.3937 [again the Z0.3937 move. why?]

N0150 Y-2.8465

N0160 Z0.3094 [z rapid .9 minus 15mm z offset]

N0170 M08

N0180 G04 P1

N0190 G01 X2.0000 F50.0

N0200 M09

N0210 G04 P0.5

N0220 G00 X0.0000 Y-3.3465

N0230 M08

N0240 G04 P1

N0250 G01 X2.0000

N0260 G00 Z-0.1969 [notice torch height is negative herefrom the -15mm z offset] [this is where i would edit Z0.9 M09]

N0270 X0.0000 Y0.0000 Z0.3937 [again the Z0.3937 move. why?]

N0280 M05 M30

(z offset -15)

N0010 (Filename: junk10.tap)

N0020 (Post processor: Mach3 THC with scriber.scpost)

N0030 (Date: 12/12/2014)

N0040 G20 (Units: Inches)

N0050 F1

N0060 G53 G90 G40

N0070 (Part: scribe test)

N0080 (Operation: No Offset, LINE, T100: Plate marker)

N0090 G00 X0.0000 Y0.5000

N0100 G28.1 Z0.12 F19.685

N0110 G92 Z0.0

N0120 G00 Z0.0520

N0130 G92 Z0.0

N0140 G00 Z0.3937 [again the Z0.3937 move. why?]

N0150 Y-2.8465

N0160 Z0.3094 [z rapid .9 minus 15mm z offset]

N0170 M08

N0180 G04 P1

N0190 G01 X2.0000 F50.0

N0200 M09

N0210 G04 P0.5

N0220 G00 X0.0000 Y-3.3465

N0230 M08

N0240 G04 P1

N0250 G01 X2.0000

N0260 G00 Z-0.1969 [notice torch height is negative herefrom the -15mm z offset] [this is where i would edit Z0.9 M09]

N0270 X0.0000 Y0.0000 Z0.3937 [again the Z0.3937 move. why?]

N0280 M05 M30

(z offset -15)

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley