(But after reading all the posts here, I kind of wish that I would have purchased a Hypertherm system just because of all of Jim's awesome help and input here, and everywhere else that he posts on the net.) Anyway I got what I got, and it seems to work fine. I don't cut much light gauge stuff, mostly 1/4 up through 3/4 in. and use the machine's oxy acct torch on the table for heavier stuff.

I have a home built compressor back in the far corner of the shop apx 48 ft. away, under the stairs that go up to the loft in the back of the shop. The compressor is a 60 gallon horizontal tank, a 2 stage compressor head from a 10HP engine driven portable rig that a friend gave me when he bought a new portable compressor yrs. ago. I run it with a Lesson 5 hp electric motor. Top air pressure shuts off at 142 lbs and I regulate to about 110 lbs to the wall filters. I have checked Jim's input about the air holding steady at required pressure, 70lbs-90lbs at torch for material being cut, and it holds the right amount of air pressure evenly all the time.

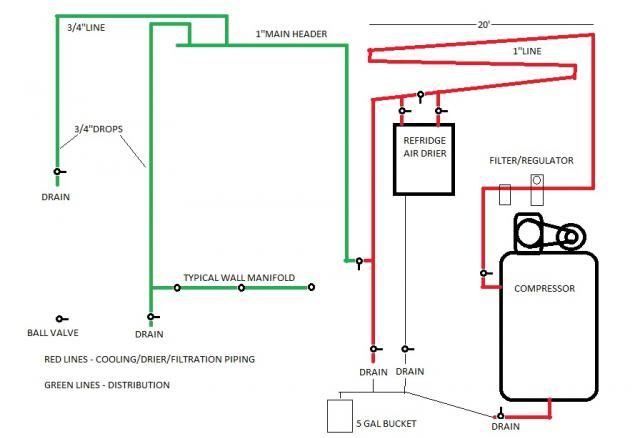

I have piping running to the front of the shop where the table is, so the run is about 48 ft., with 4 drops along the wall with ball valves at the bottom of each drop to drain if it were necessary. The table is connected to the last drop in the front of the shop. This is the order that everything hooks up from there.

From the wall fitting a line runs to a harbor freight desiccant filter, then to a motor guard M26 paper filter, then to the A120. I had hoped that by running the air all the way from the back of the shop to the front of the shop that most moisture would be out of the air by the time it got to, and through the 2 filters at the A120. I know the humidity is extremely high here in the greater Seattle Area, particularly in the winter. Whenever I open the ball valve on the bottom of the tank, (I do this every time I go back to change a Johnny Cash cd for a Tanya Tucker one, or a Hank Snow, Ha Ha,,,) water pours out of the tank and then eventually blows clear. Probably about 5 to 10 seconds. Then I always open the next drop along the wall to check how the air feels, then go back front to the table to work. I am frustrated,

I never get more than 50 to 65 pierces from an electrode before the torch begins not wanting to fire, so I change to a new electrode, and sometimes a tip if the parts being cut need a better edge. Then things are back to normal for another 50 or 60 pierces. I run very close to book specs and keep a log of all cuts. This is real frustrating when you have a few 100 gussets to cut or something else of quantity.

Do I defiantly need a refrigerant air dryer for my system? Will it get me into the 100 to 300 pierces that I read about everywhere. Is the unit sold here a good quality one, the macair? I see that Ingersoll rand makes some small units too, as well as speed air, and hankison. All in the 500.00 to 900.00 range. My table works well, my cut quality seems fine, but I just can?t get the amount of pierces that I hear about on plasma spider or elsewhere.

Also how would I size a dryer for my A120, is this little macair unit big enough for what i have. Help.

Thanks in Advance. Frustrated in Seattle plasmafab