Picked up this compressed air dryer from HF online.

http://www.harborfreight.com/compressed ... 40211.html

The regulator on the compressor broke so I've been using a 3 foot hose to another regulator, then the motorguard m60 filter.

I am using this 29 gallon compressor http://www.harborfreight.com/29-gal-2-h ... 61489.html

Now that I have the air dryer, what's the best/correct order to plumb it all in?

I was thinking the compressor -> regulator -> air dryer -> motorguard m60 -> hypertherm air filtration kit (on back of the plasma)

Or do I put the regulator after the air dryer?

Air Dryer install?

-

gamble

- 4 Star Member

- Posts: 950

- Joined: Thu Jan 02, 2014 6:33 pm

Air Dryer install?

Torchmate 2x2 - Flashcut

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

-

Dana gear

- 2 Star Member

- Posts: 54

- Joined: Fri Jan 13, 2017 10:55 pm

Re: Air Dryer install?

We always plumbed our air systems in this order, Air Compressor then water traps with automatic drains (we run two) then on to air drier after that Motor guard air filters and at the end the air regulators. Keep the moisture out of the regulators.

The Hypertherm units we operate have coalescing units on them.

Everybody's needs and uses are different, we have a little higher humidity at time here.

We run both piston and rotary screw compressors and when we are at full throttle the automatic drains on the water traps combined probably dump a gallon of water in a 12 hour cycle and even the driers dribble a little all day.

The Hypertherm units we operate have coalescing units on them.

Everybody's needs and uses are different, we have a little higher humidity at time here.

We run both piston and rotary screw compressors and when we are at full throttle the automatic drains on the water traps combined probably dump a gallon of water in a 12 hour cycle and even the driers dribble a little all day.

-

gamble

- 4 Star Member

- Posts: 950

- Joined: Thu Jan 02, 2014 6:33 pm

Re: Air Dryer install?

I just got done playing and right now i have it as this

compressor -> regulator -> m60 -> dryer

The regulator has a water trap built in. Is that ok or do I need a different one? Looking to keep this as maintenance free as possible too.

Next I need to find a 90* fittings and short pipe so I can add a drain to the comrpessor without getting under it.

compressor -> regulator -> m60 -> dryer

The regulator has a water trap built in. Is that ok or do I need a different one? Looking to keep this as maintenance free as possible too.

Next I need to find a 90* fittings and short pipe so I can add a drain to the comrpessor without getting under it.

Torchmate 2x2 - Flashcut

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

-

urbnsr

- 3 Star Member

- Posts: 329

- Joined: Wed Dec 26, 2012 6:13 am

Re: Air Dryer install?

I don't know which way is better, but this is what I have tried -

Going off of the diagrams I have seen, I have compressor, main regulator with simple water trap, dryer, water trap, air filter, oil filter, and then desiccant dryer. Everything after the dryer was installed to mainly do the job of the dryer to keep moisture out (dirt, too). Now that I have a dryer, I can see the desiccant dryer's pink silica has returned to a white/opaque color and aft water traps have never had any water in them since the dryer was installed. I am almost ready to reduce the number of filters (obstructions) after the dryer, but haven't yet. I believe the water traps work more efficiently when the air is cooler. The main reason I have a regulator before is to protect anything from the higher PSI that the compressor can produce which is higher than the max rating of the dryer and filters in use.

I have not used the motorguard m60 filter, but thought these elements can get saturated greatly reducing air flow. I don't know this, just assuming, guessing.

I have installed 90°elbow under the compressor. Highly recommended!

Going off of the diagrams I have seen, I have compressor, main regulator with simple water trap, dryer, water trap, air filter, oil filter, and then desiccant dryer. Everything after the dryer was installed to mainly do the job of the dryer to keep moisture out (dirt, too). Now that I have a dryer, I can see the desiccant dryer's pink silica has returned to a white/opaque color and aft water traps have never had any water in them since the dryer was installed. I am almost ready to reduce the number of filters (obstructions) after the dryer, but haven't yet. I believe the water traps work more efficiently when the air is cooler. The main reason I have a regulator before is to protect anything from the higher PSI that the compressor can produce which is higher than the max rating of the dryer and filters in use.

I have not used the motorguard m60 filter, but thought these elements can get saturated greatly reducing air flow. I don't know this, just assuming, guessing.

I have installed 90°elbow under the compressor. Highly recommended!

Last edited by urbnsr on Wed Apr 26, 2017 6:27 am, edited 1 time in total.

-

Old Iron

- 3.5 Star Member

- Posts: 681

- Joined: Wed Nov 26, 2014 5:12 pm

Re: Air Dryer install?

If you leave the cartridge in the m60 long enough to be saturated, you've messed up big time.

The cartridges are to be changed out at least once a week. The aluminum will corrode under the powder coat and it will peal off. As the ole saying goes, ask me how I know

The air flow is not diminished enough to even notice.

In my opinion, the M60 is like money in the bank.

The cartridges are to be changed out at least once a week. The aluminum will corrode under the powder coat and it will peal off. As the ole saying goes, ask me how I know

The air flow is not diminished enough to even notice.

In my opinion, the M60 is like money in the bank.

-

gamble

- 4 Star Member

- Posts: 950

- Joined: Thu Jan 02, 2014 6:33 pm

Re: Air Dryer install?

I hope not, those filters are $20 a pieceOld Iron wrote:If you leave the cartridge in the m60 long enough to be saturated, you've messed up big time.

The cartridges are to be changed out at least once a week. The aluminum will corrode under the powder coat and it will peal off. As the ole saying goes, ask me how I know

The air flow is not diminished enough to even notice.

In my opinion, the M60 is like money in the bank.

Torchmate 2x2 - Flashcut

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

Powermax 45 - Machine torch

Taig CNC Mill - Flashcut

Razorweld Distributor

- WyoGreen

- 4 Star Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Air Dryer install?

I'd say the change interval on a M60 depends on where you live. I live in whats considered a high altitude desert. My M60 filter has been in for 4 years now, and still shows absolutely no sign of moisture. I check it often especially when it rains, but all my moisture seems to be caught clear back at the compressor, with a tiny little bit once in a long while caught in my filter/regulator before the M60.

Steve

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

Old Iron

- 3.5 Star Member

- Posts: 681

- Joined: Wed Nov 26, 2014 5:12 pm

Re: Air Dryer install?

gamble wrote:I hope not, those filters are $20 a pieceOld Iron wrote:If you leave the cartridge in the m60 long enough to be saturated, you've messed up big time.

The cartridges are to be changed out at least once a week. The aluminum will corrode under the powder coat and it will peal off. As the ole saying goes, ask me how I know

The air flow is not diminished enough to even notice.

In my opinion, the M60 is like money in the bank.

I started with three and in a year I'm still using the same three.

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Air Dryer install?

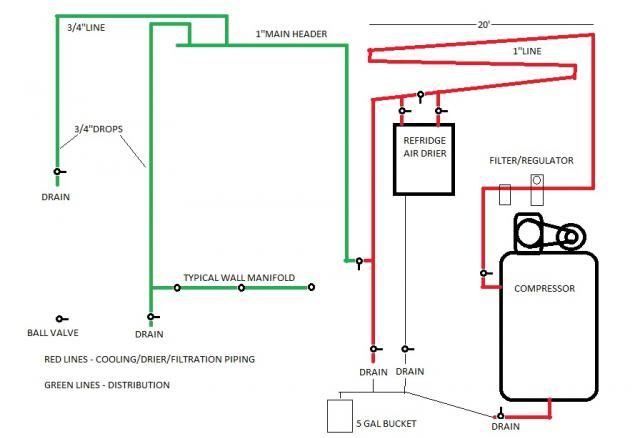

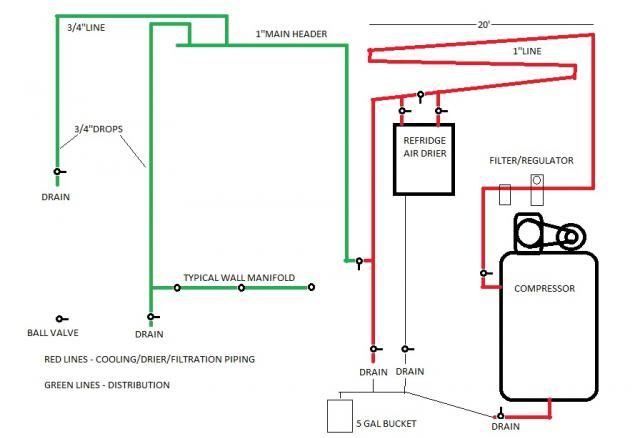

the cooler the air is going into the air dryer the more efficient it will be

if you using rubber hose and daisy chain the components together you have marginal value from the air dryer

50 feet of copper pipe between the compressor to the first component will help a lot to drop the air temps

it doesn't need to be straight pipe, this one is a little extreme but it fits in the space provided and uses one drain

at the shop we dry air for plasma and a paint booth, we rarely have moisture in the red lines

usually due to a malfunction

if you using rubber hose and daisy chain the components together you have marginal value from the air dryer

50 feet of copper pipe between the compressor to the first component will help a lot to drop the air temps

it doesn't need to be straight pipe, this one is a little extreme but it fits in the space provided and uses one drain

at the shop we dry air for plasma and a paint booth, we rarely have moisture in the red lines

usually due to a malfunction

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- steel 35

- 3.5 Star Member

- Posts: 634

- Joined: Sun Jan 11, 2015 11:12 am

- Location: N of Cali.

Re: Air Dryer install?

gamble wrote:I just got done playing and right now i have it as this

compressor -> regulator -> m60 -> dryer

The regulator has a water trap built in. Is that ok or do I need a different one? Looking to keep this as maintenance free as possible too.

Next I need to find a 90* fittings and short pipe so I can add a drain to the comrpessor without getting under it.

(compressor -> regulator -> dryer -> m60)

PPL HDG 4X8

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber